Full-angle high-luminance light-emitting lamp filament bulb and manufacturing method thereof

A full-angle lighting, high-illuminance technology, applied in the field of lighting, can solve the problems of low illumination, difficult lighting industry and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiment 1 of the present invention will be further described below in conjunction with the accompanying drawings.

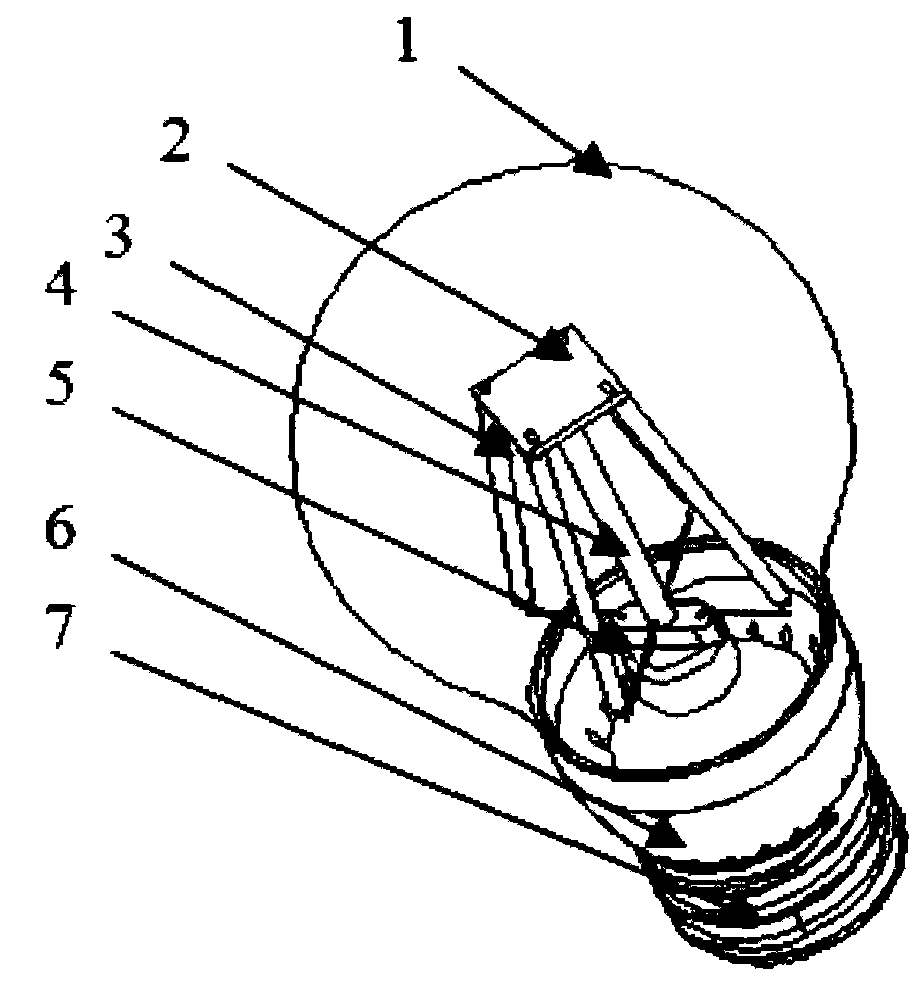

[0030] The present invention proposes an all-angle light bulb, its structure is as follows figure 1 As shown, it includes full-angle light-emitting filament 3, stem 4, LED light-emitting substrate 2, lampshade 1, heat-conducting gas 5, lamp cap plastic part 6, lamp cap 7; one end of the stem 4 is provided with a bell mouth to communicate with the The lampshade mouth of the lampshade 1 forms a sealed lamp body, and the lamp body is provided with a stem exhaust pipe, and the heat-conducting gas 5 is punched in the lamp body, and the lamp body is connected to the plastic part 6 of the lamp cap. There is a lamp holder 7 outside; the stem 4 extends into the lampshade 1; the stem 4 extends into the lampshade 1; Angle luminous filament; one end of the full-angle luminous filament is connected to the conductive lead wire on the stem 4, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com