Fixing structure of drying agents for automobile lamp

A fixed structure, desiccant technology, applied in the direction of light source fixation, fixed lighting devices, motor vehicles, etc., can solve the problems of affecting the next assembly process, the adhesion is not firm, and the drying effect is lost, so as to solve the fogging problem and facilitate replacement. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

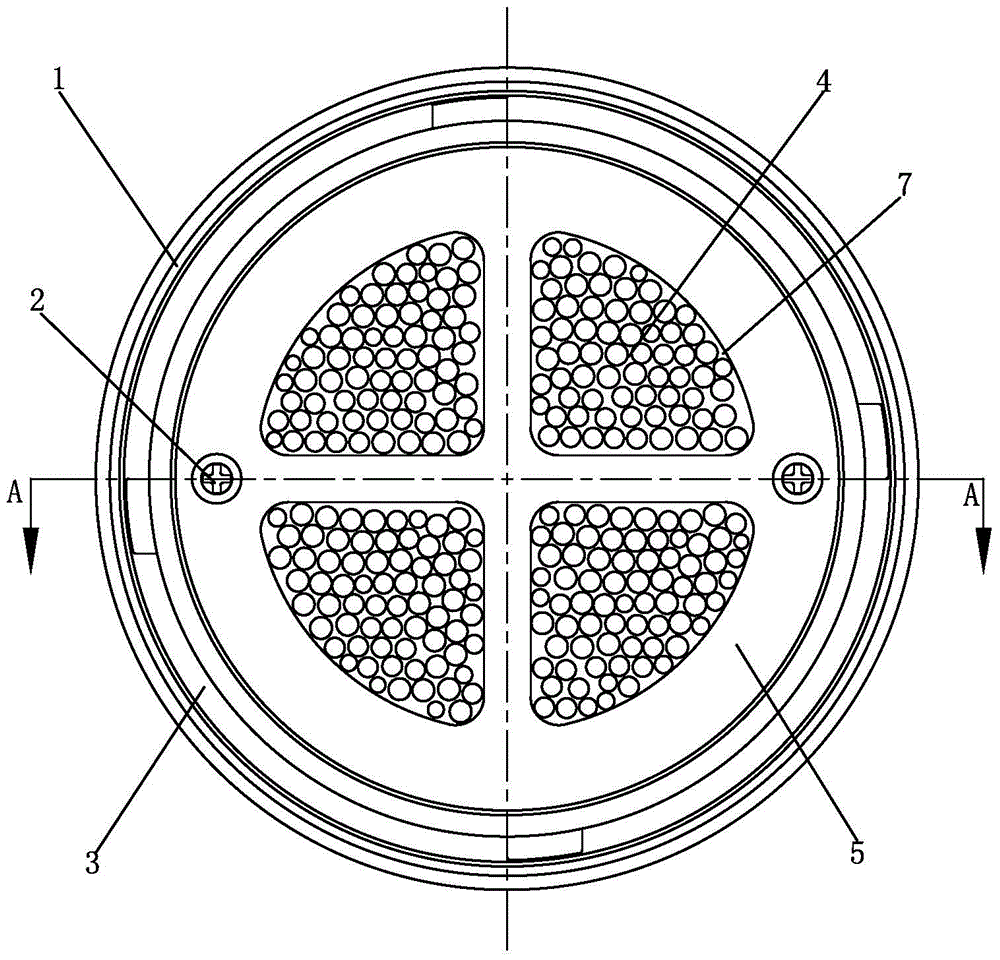

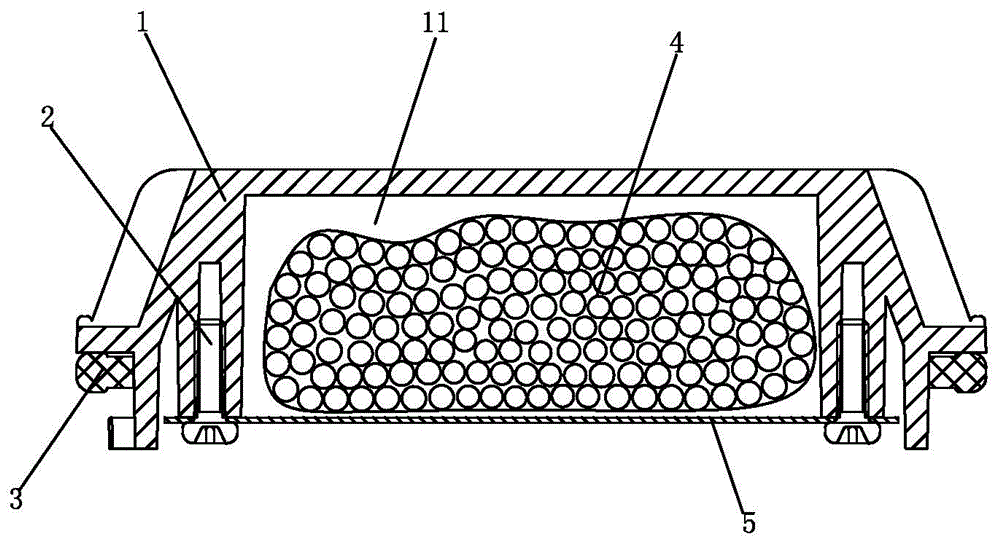

[0015] see figure 1 , 2 , a fixing structure for a desiccant for car lights, comprising a back cover 1 and a pressure ring 5, the back cover 1 is provided with a storage tank 11 for storing the desiccant 4, the pressure ring 5 is fixed on the back cover 1 to seal the desiccant 4 In the storage tank 11, the desiccant 4 is first placed in the storage tank 11, and then the pressure ring 5 is installed in the two screw holes on the rear cover 1 through two self-tapping screws 2 to complete the fixing of the desiccant 4; 5 is provided with two or more desiccant ventilation holes 7, which can be used for the air circulation between the desiccant and the lamp body and can absorb the moisture in the lamp body.

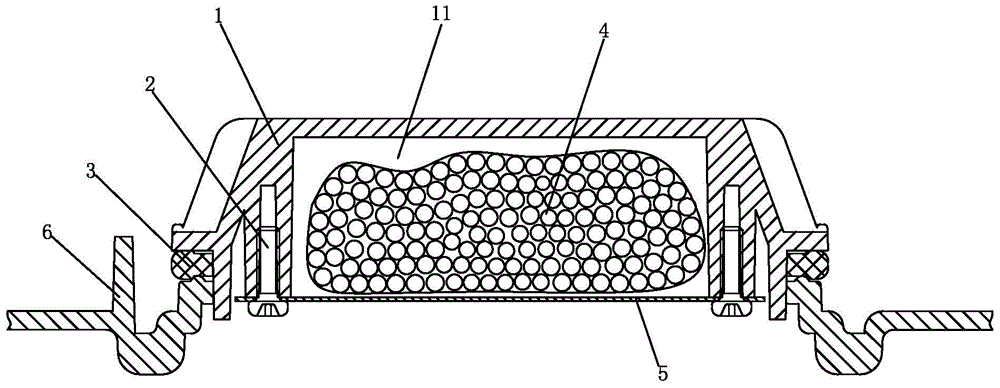

[0016] Such as image 3 It is a schematic diagram of the cooperation between the present invention and the lamp body. The desiccant 4 is fixed in the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com