Laser Ignition Liquid Fuel Burner

A technology of laser ignition and liquid fuel, which is applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of insufficient safety and reliability, difficulty in controlling ignition time, poor anti-interference ability, etc., and achieve control of ignition intensity and ignition time , avoid multiple ignition, safe and reliable ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

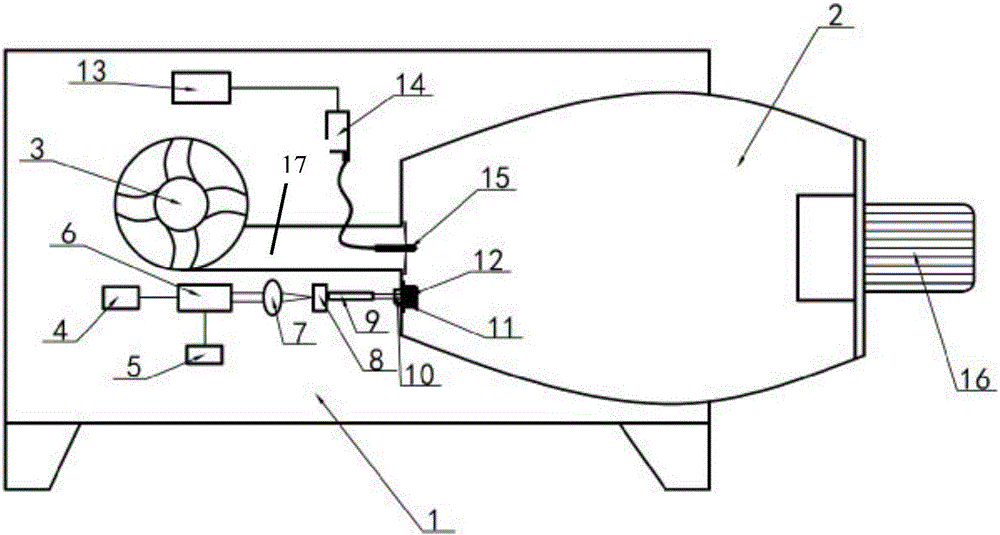

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited thereto.

[0017] like figure 1 As shown, the laser ignition liquid fuel burner of the embodiment of the present invention includes a body 1, the front end of the body 1 is provided with an arc-shaped groove, and the combustion chamber 2 with an arc-shaped outer peripheral surface is fixed at the arc-shaped groove, and the combustion chamber 2 The right end face is pierced with a combustion head 16, and the combustion head 16 part extends into the combustion chamber and is closely connected with the combustion chamber 2. The body 1 is also provided with an air supply device 3, a fuel supply device and a laser ignition device, and the air supply device 3 is supported by a bracket and fixed on the body 1 through the bracket, and the outlet pipe 17 of the air supply device 3 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com