Metallic magnesium reduction tank changing method and device

A reduction tank and metal magnesium technology, which is applied in the special equipment for metal magnesium smelting and the field of metal magnesium reduction tank replacement, can solve problems such as loosening, furnace wall falling off, and uneven business quality, so as to reduce gaps, prolong service life, The effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1 A kind of metal magnesium reduction tank replacement tank method and device composition and effect of each part:

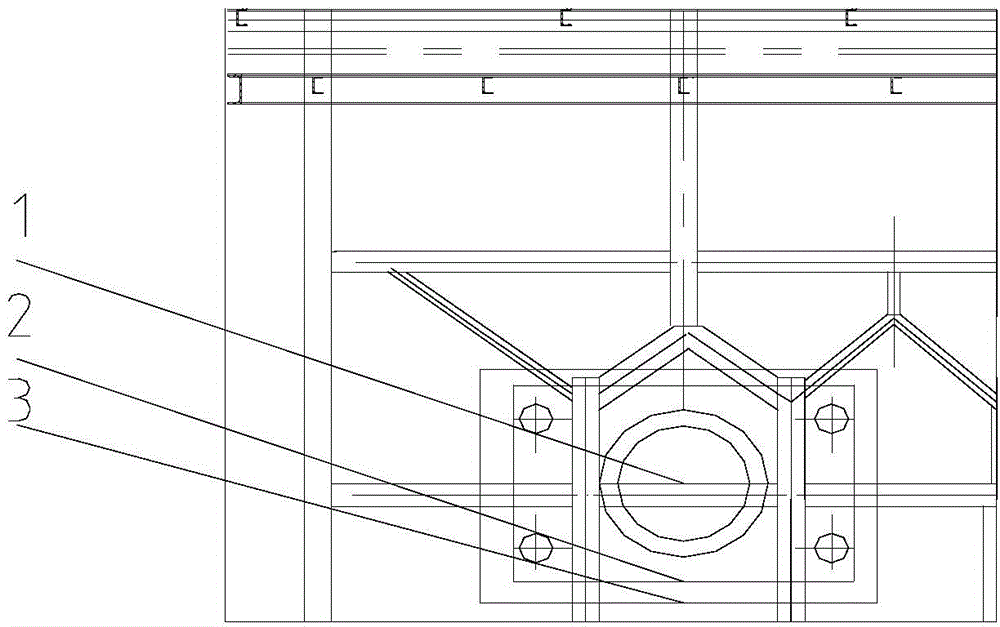

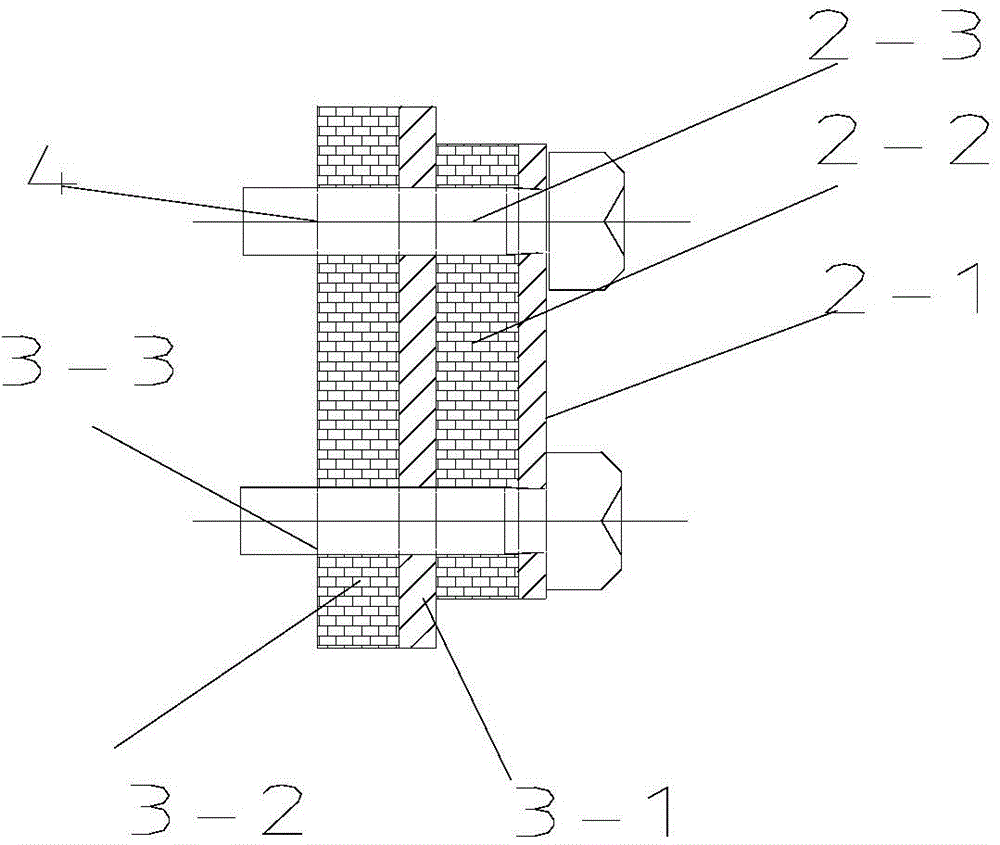

[0013] The can changing device consists of a reduction tank 1, a refractory brick structure part 2 set for the tank body, a tank change structure part 3 of the reduction furnace set, and a connecting bolt 4. It is characterized in that it is a method and device for changing a metal magnesium reduction tank. , the refractory brick structure part 2 of the tank body is connected or disassembled and replaced with the tank replacement structure part 3 of the reduction furnace set by using the connecting bolt 4 . The refractory brick structure part 2 of the tank body is composed of a surface metal plate 2-1, a lining refractory brick 2-2, and connecting bolt holes 2-3. The can replacement structure part 3 of the reduction furnace set is composed of a surface metal plate 3-1, a lining refractory brick 3-2, and a connecting bolt hole 3-3.

Embodiment 2

[0014] Embodiment 2 A kind of metal magnesium reduction tank replacement method and device working process:

[0015] When changing the tank, spot-weld the refractory brick structure part 2 of the tank body on the reduction tank 1, and then connect the tank change structure part 3 of the reduction furnace set on the reduction furnace wall with the connecting bolt 4 to get final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com