Hole and end face perpendicularity test tool

A technology of verticality and inspection tools, applied in measuring devices, instruments, and mechanical devices, etc., it can solve the problem that the accuracy of detection results is limited by the operator's detection operation level, the shape error of the large hole of the connecting rod has a great influence, and it is difficult to adapt to production, etc. problem, to achieve the effect of high parallelism, good integrity and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

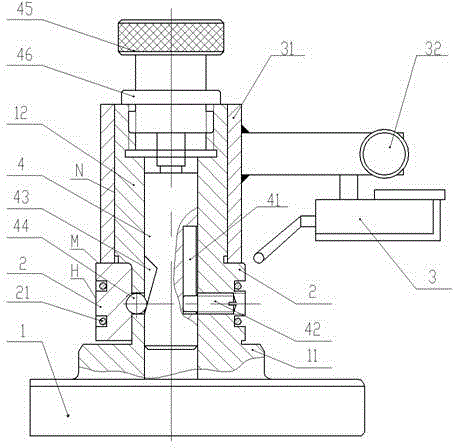

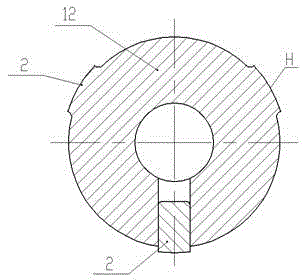

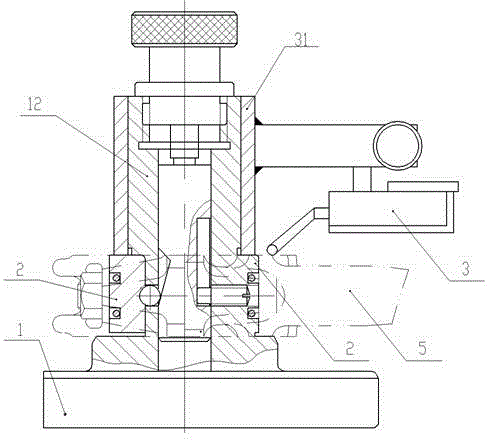

[0029] The inspection tool for verticality between the hole and the end surface of the present invention includes a main body 1 of the inspection tool, and three positioning blocks 2 are arranged along the circumference of the main body of the inspection tool 1 for axial positioning and installation of the inner diameter surface of the workpiece hole to be inspected, at least one of which is The three positioning blocks 2 can be adjusted radially on the main body 1 of the inspection tool. The main body 1 of the inspection tool is also provided with a detection meter 3 that can rotate around the axis, and the axis and detection table composed of three positioning blocks 2 The axes of rotation in Table 3 are parallel or coincident.

[0030] The outer diameter surface of the positioning block 2 is an arc structure, and its arc diameter is smaller than or equal to the inner diameter of the workpiece hole to be detected, and the detection gauge 3 is a dial indicator or a dial gauge....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com