Ultrasonic flow meter

A flowmeter and ultrasonic technology, applied in the field of ultrasonic flowmeters, can solve problems such as disturbing the propagation of sound wave signals and reducing the accuracy of measuring liquid flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

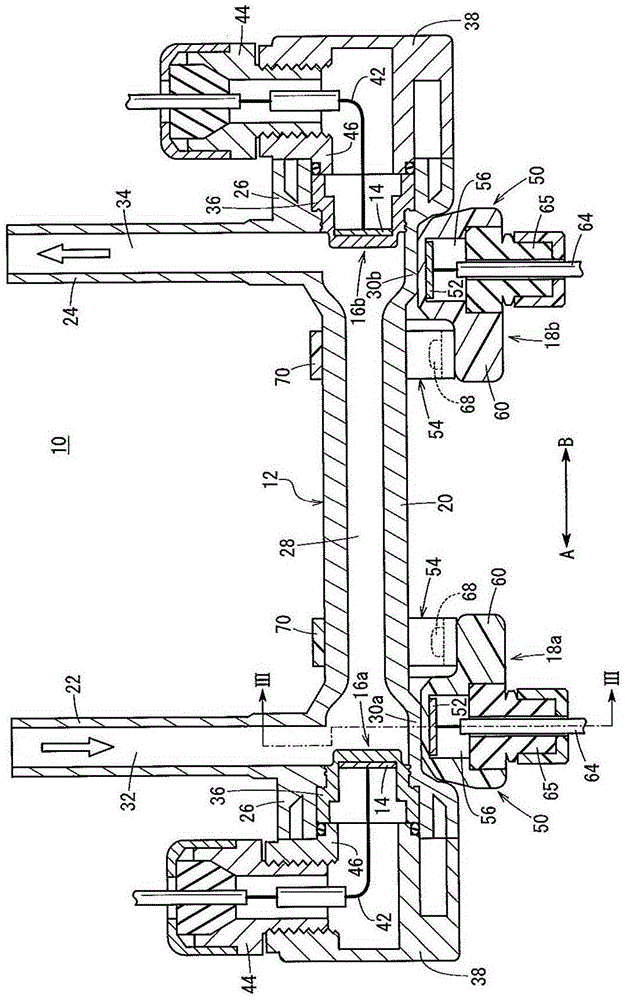

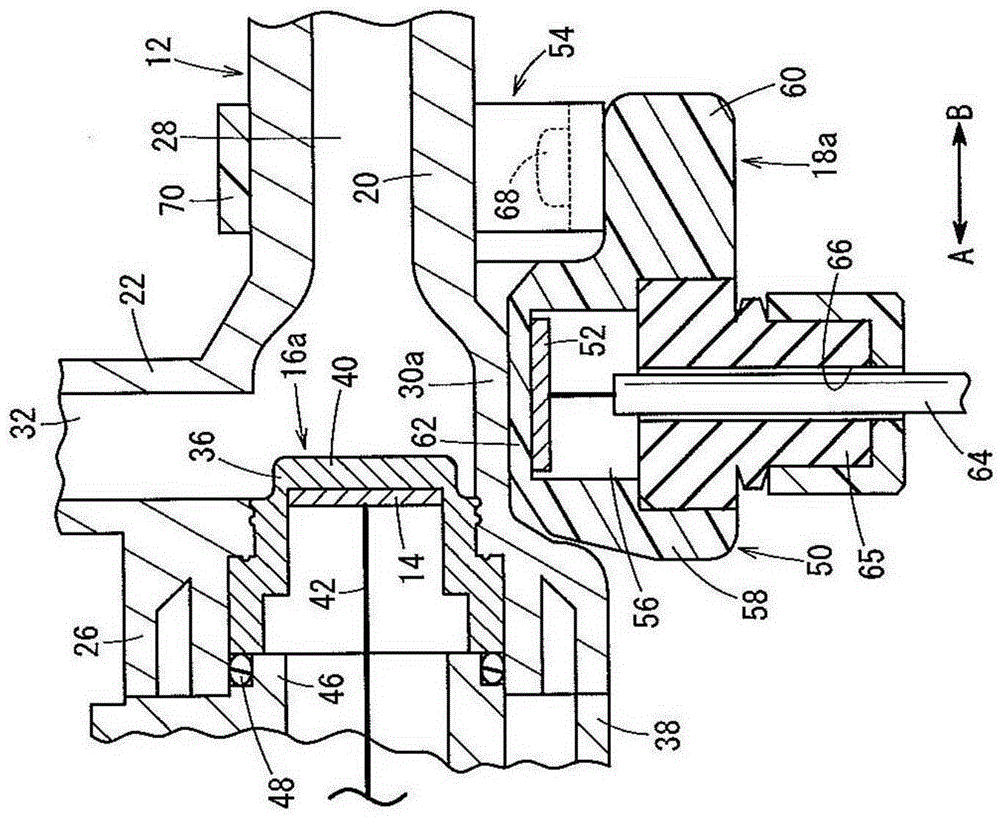

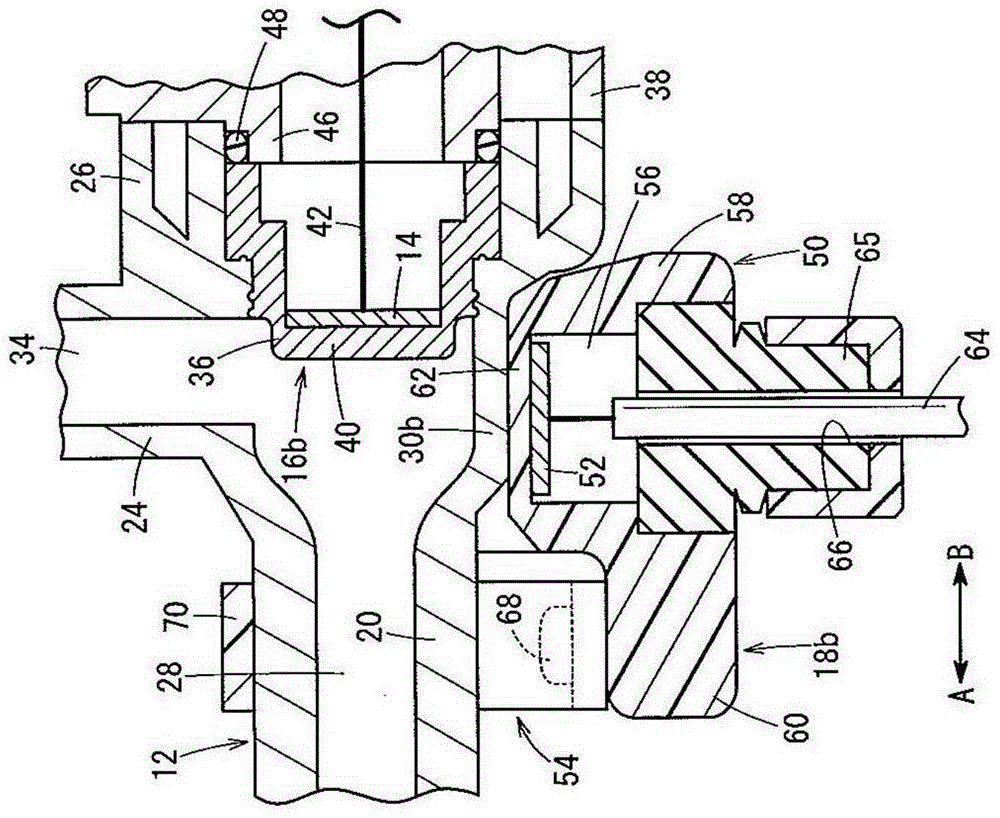

[0015] Such as figure 1 As shown, an ultrasonic flowmeter 10 according to an embodiment of the present invention includes: a housing (housing) 12 having a passage 28 to which fluid such as water, chemical solution, etc. is supplied; a pair of detection units 16a, 16b, The detection unit is arranged on the opposite end of the casing 12, and is installed therein an acoustic wave transmitting and receiving unit 14 for transmitting and receiving acoustic waves; and a pair of vibration generating mechanisms 18a, 18b, which are provided on the detecting unit. The position on the outer peripheral side of l6a, l6b.

[0016] The housing 12 includes: a piping 20 formed in a straight line of, for example, a metallic material such as stainless steel; a supply portion (port) 22 connected substantially perpendicularly to one end of the piping 20; and a discharge portion (port) 24 , the discharge portion is connected substantially perpendicular to the other end of the pipeline 20 . The sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com