Mechanical connection structure for detecting dynamic torque by adopting static torque sensor

A technology of mechanical connection structure and static torque, which is applied in the direction of instruments, measuring devices, torque measurement, etc., can solve the problems of high cost of dynamic torque detection of motor shaft, inaccurate and stable detection data, complex structure of dynamic torque sensor, etc. Achieve the effect of simple structure, improved accuracy and stability, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

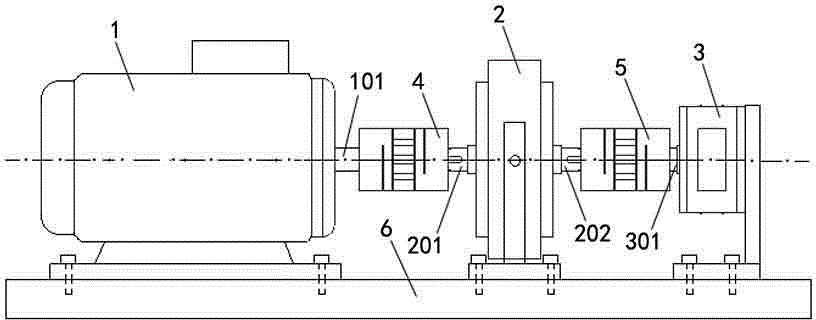

[0022] See figure 2 , the motor 1 to be detected, the magnetic powder clutch 2 and the static torque sensor 3 are installed coaxially on a metal platform 6 through couplings 4 and 5 . The coupling 4 coaxially connects the drive shaft 201 of the magnetic powder clutch 2 with the rotating shaft 101 of the motor 1 , and the coupling 5 coaxially connects the driven shaft 202 of the magnetic powder clutch 2 with the detection shaft 301 of the static torque sensor 4 . Then the magnetic powder clutch 2 is connected with the power supply, and the torque digital display instrument is connected with the power supply and the static torque sensor 3 . Turn on the power supply of the motor 1 to start the motor 1, adjust the working current of the magnetic powder clutch 2, and this current makes the friction disc fixed together with the driven shaft 202 inside the magnetic powder clutch 2 and the friction disc fixed together with the drive shaft 201 to generate Mechanical friction coupling...

Embodiment 2

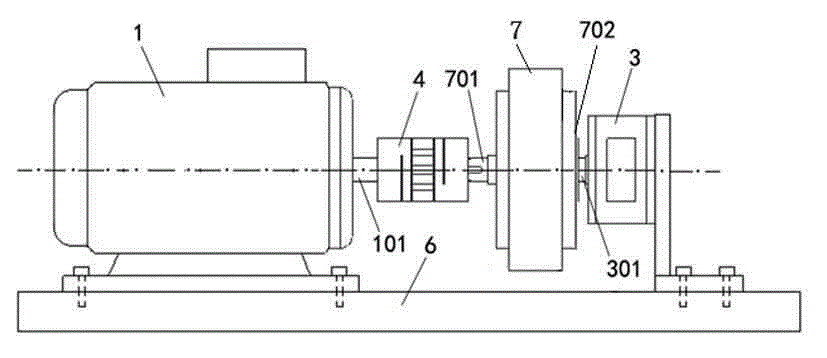

[0024] See image 3 , similar to Embodiment 1, the difference is that the motor 1 to be tested, the magnetic powder brake 7 and the static torque sensor 3 are installed coaxially on a metal platform 6 through a coupling 4 . That is, the rotating shaft 701 of the magnetic powder brake 7 is connected to the rotating shaft 101 of the motor 1 through the coupling 4 . The rear casing 702 of the magnetic powder brake 7 opposite to the rotating shaft 701 is coupled with the detection shaft 301 of the static torque sensor 3 . Then the magnetic powder brake 7 is connected with the power supply, and the torque digital display instrument is connected with the power supply and the static torque sensor 3 . Turn on the power supply of the motor 1 to start the motor 1, adjust the working current of the magnetic powder brake 7, this current makes the friction disc fixed together with the 7 rotating shaft 701 inside the magnetic powder brake and the friction plate fixed together with the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com