Pixel structure and electrowetting display device comprising same

A pixel electrode and pixel technology, applied in the field of electrowetting display devices, can solve problems such as poor stability, achieve the effect of increasing storage capacitance and improving display stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

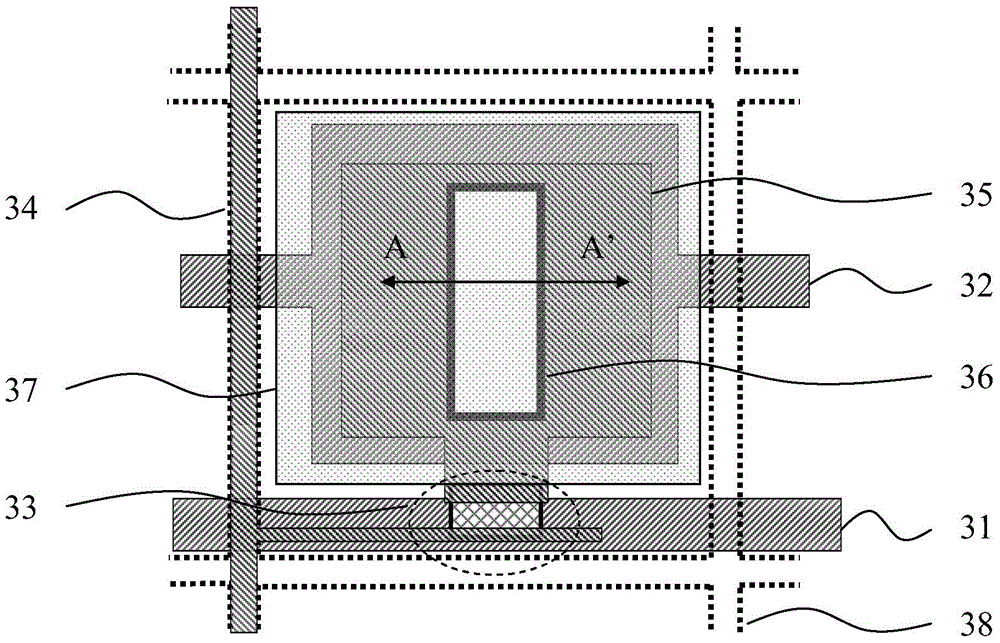

[0035] Figure 4 It is a schematic plan view of the pixel structure in Embodiment 1 of the present invention. Such as Figure 4 As shown, in the pixel structure, the storage capacitor is formed by the first metal layer M1, the gate insulating layer GI, the second metal layer M2, the passivation layer PAS, and the ITO transparent electrode layer. The size of the storage capacitor is increased through the double storage capacitor structure of the upper and lower layers, and the stability of the display is improved.

[0036] Such as Figure 4 As shown: the array substrate described in Embodiment 1 is sequentially distributed on the substrate as the scanning line 31 composed of the first metal layer M1, the common electrode connecting line segment 32a, and the metal pixel electrode 35; the array substrate composed of the second metal layer M2 Data line 34 , common electrode 32 b , pixel electrode connection line 39 . It also includes an extension of the data line 34 along the ...

Embodiment 2

[0047] Image 6 It is a schematic plan view of the pixel structure of Embodiment 2 of the present invention. Such as Image 6 As shown, in the pixel structure, the storage capacitor is formed by the metal layer M1, the gate insulating layer GI, the metal layer M2, the passivation layer PAS, and the ITO transparent electrode layer. The size of the storage capacitor is increased through the double storage capacitor structure of the upper and lower layers, and the stability of the display is improved.

[0048] Such as Image 6 As shown: the array substrate described in Embodiment 2 is sequentially distributed on the substrate as a scanning line 31 composed of the first metal layer M1, a common electrode connection line segment 32a, and a metal pixel electrode 35; Data line 34 , common electrode 32 b , pixel electrode connection line 39 . The scan line 31 , the semiconductor layer, the data line 34 , and the pixel electrode connection line 39 form a conventional thin film tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com