Circle shear overlap amount controller parameter optimizing method based on brainstorming

A technology of brainstorming and optimization methods, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems that affect product quality, difficult to achieve optimal control, and control accuracy cannot meet technical requirements, and achieve improved control. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

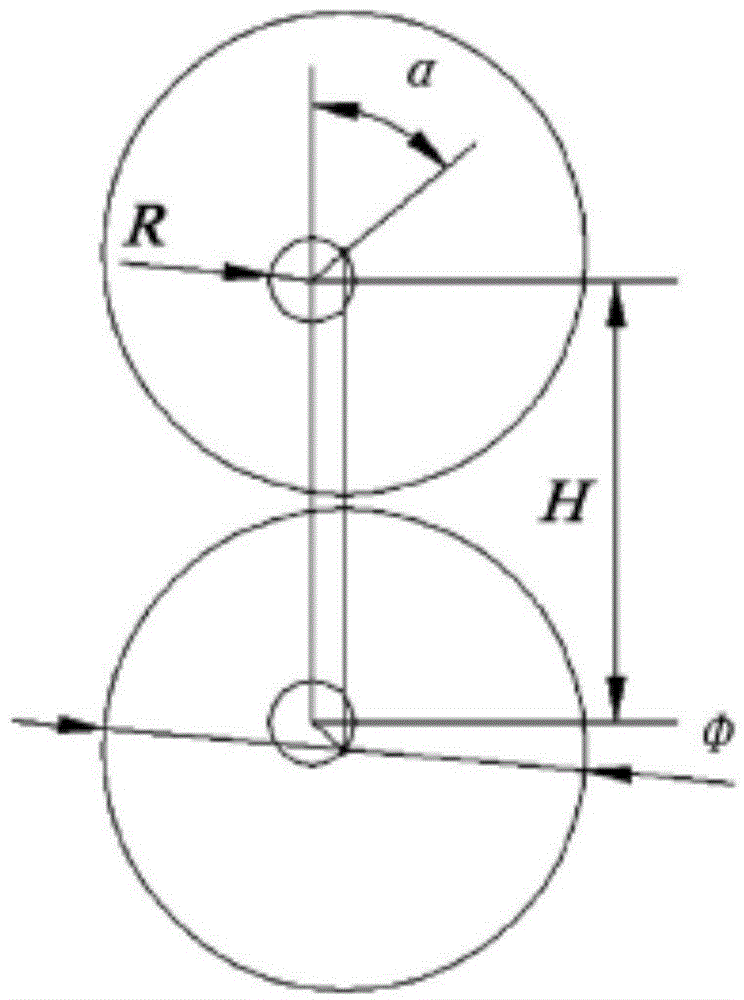

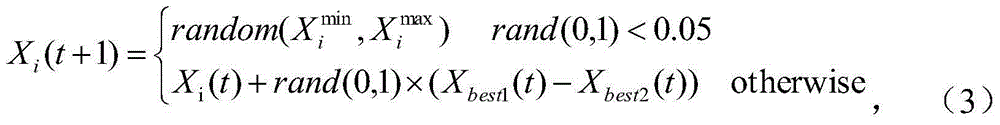

[0033] The method of the present invention aims to learn from the optimization idea of brainstorming, aiming at the mathematical model between the change of overlapping amount and the rotation angle of the eccentric sleeve, to solve the control problem of cutting edge disc shears in the field of industrial control, and to use the brainstorming idea to control the disc shears. The controller parameters of shear overlap are optimized and adjusted to solve the quality problems caused by some bad cutting that may occur when the disc shears trim the steel plate.

[0034] The brainstorm-based parameter optimization method of the disk shear overlap controller in the present invention is specifically implemented according to the following steps:

[0035] Step 1: Establish a mathematical model for parameter control of the overlap amount

[0036] re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com