Active flexible heating body and preparing method and application of active flexible heating body

A heating element and flexible technology, which is applied in the field of new heating materials, can solve the problems that the heating temperature cannot reach a high value, does not have compression resistance, bending resistance, and has large application limitations, and can meet the needs of irregular heating or flexible heating. , Change the effect of poor softness and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

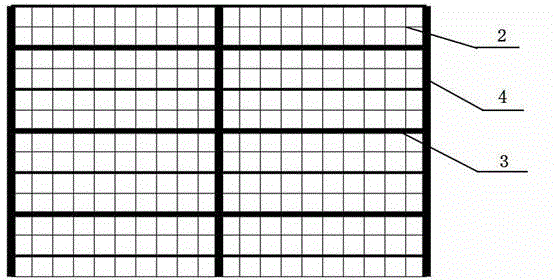

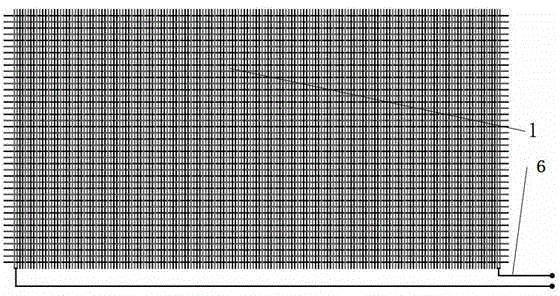

[0027] Such as figure 2 As shown, an active flexible heating element 1 is connected to a power source through a conductive wire 2, and the active flexible heating material 1 can generate heat evenly.

Embodiment 2

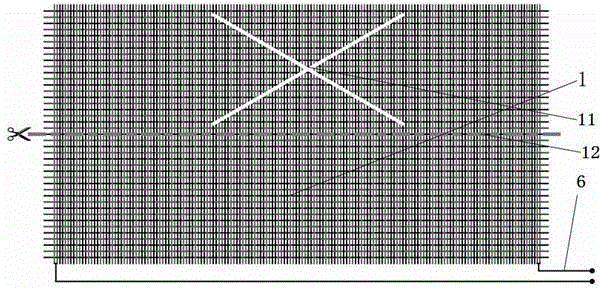

[0029] Such as image 3 As shown, an active flexible heating element 1 cuts off a part 11 of the heating element along the cutting line 12, and the heating element 1 is connected to a power supply through a wire 6, so that an active flexible heating material 1 can generate heat evenly, and The heating effect at the same voltage is equivalent to that of Example 1; since the heating body provided by the application combines electrodes and heating materials in an interlaced manner, the resulting corresponding products can be cut horizontally and vertically, and can be changed by selecting different heating materials The power of the heating body is then adapted to the needs of different fields.

Embodiment 3

[0031] Such as Figure 4 As shown, an active flexible heating element 1 is covered with an insulating film 5 on both sides, the lowermost layer 9 is a heat insulating layer, and the uppermost layer 10 is a surface layer. An active flexible heating element 1 is connected to a power supply and a controller 8 through a wire 6 , then an active flexible heating material 1 can be made into a blanket-shaped heating body, wherein the surface layer 10 can be floor leather, carpet, bamboo mat, heat-resistant cloth or other sheet-like items in industrial and agricultural production and daily life.

[0032] Applied in agricultural production to provide heat for overwintering plants such as Figure 5 shown;

[0033] Similar heating elements can also be used in aquaculture, such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com