Multipart insulating element, in particular for a fuel injection device

A technology for a fuel injection device and an isolating element, which is applied in the directions of a fuel injection device, a special fuel injection device, a fuel injection device with noise reduction measures, etc. Stress reduction, improved noise damping, reduced deflection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

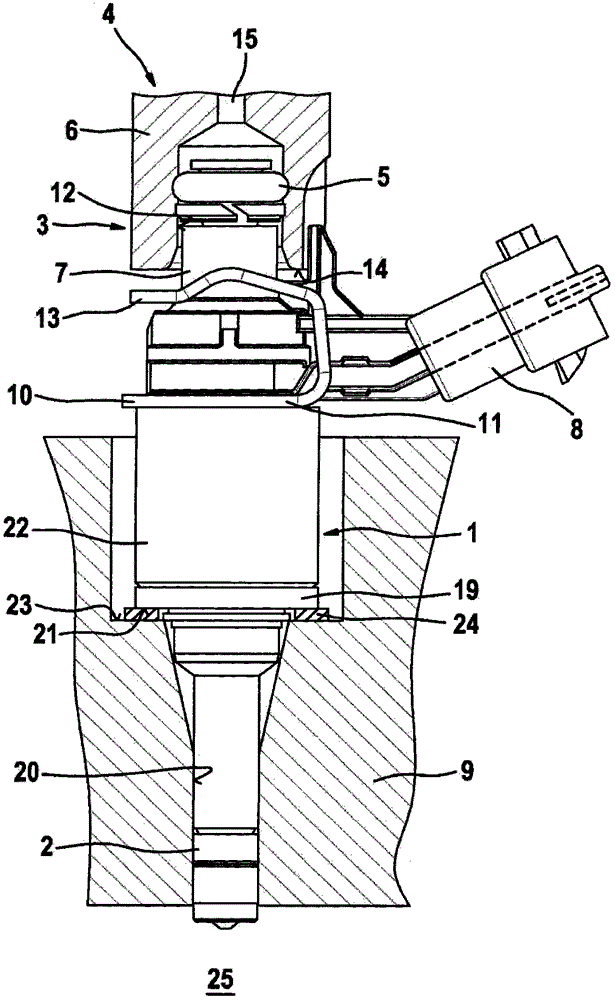

[0020] In order to understand the present invention, next by means of figure 1 Known embodiments of fuel injection systems are described in more detail. figure 1 An exemplary embodiment of a valve in the form of an injection valve 1 for a fuel injection system of a hybrid compression external ignition internal combustion engine is shown in side view. The fuel injection valve 1 is part of a fuel injection system. The fuel injector 1 , which is designed as a direct injection valve for injecting fuel directly into the combustion chamber 25 of the internal combustion engine, is inserted with its downstream end into the receiving bore 20 of the cylinder head 9 . Sealing ring 2 (especially made of Teflon constituted) for optimal sealing of the fuel injector 1 against the wall of the receiving bore 20 of the cylinder head 9 .

[0021] A flat intermediate element 24 is inserted between the shoulder 21 of the valve housing 22 and the projection 23 of the receiving opening 20 , whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com