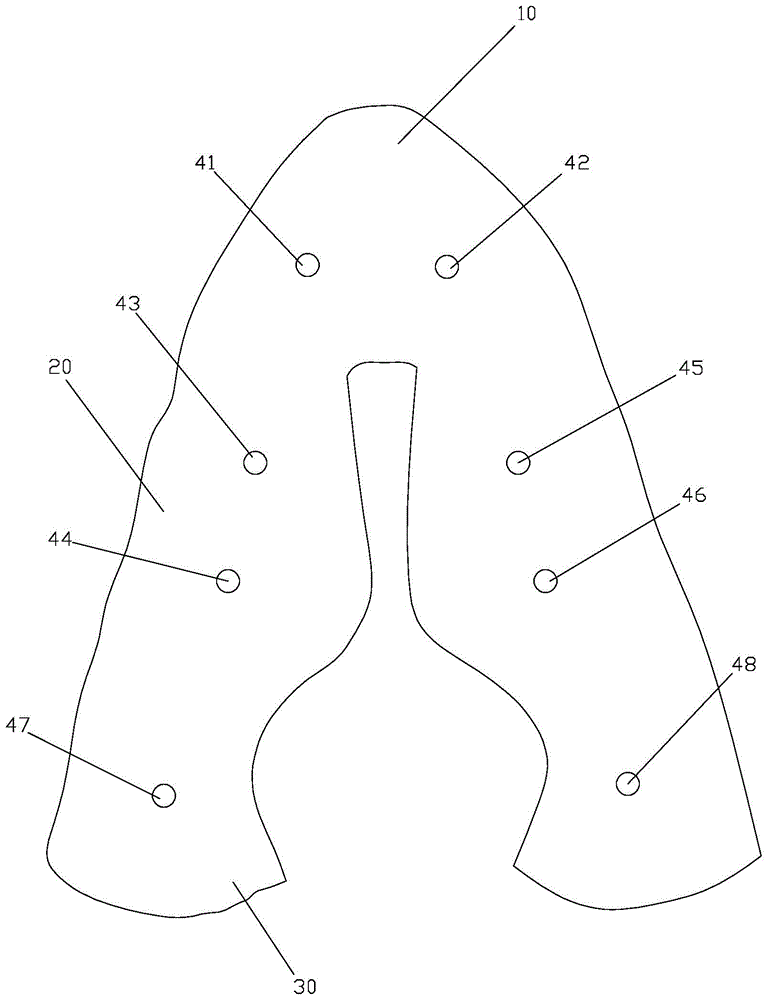

Method for manufacturing integral flat knitted shoe uppers

A manufacturing method and flat knitting technology, which is applied to shoe uppers, footwear, boot legs, etc., can solve problems such as inability to meet special requirements for shoe uppers, and achieve the goals of improving market competitiveness, reducing material costs and labor costs, and reducing manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for manufacturing an integrated horizontally knitted shoe upper, comprising the following steps:

[0023] 1. Special yarn for weaving shoe heels: 1 piece of 150D hot-melt yarn and 3 pieces of 150D polyester yarn, using air-covered yarn technology.

[0024] 2. Special yarn for weaving the middle surface of shoes: one 210D spandex yarn as the core material and one 150D polyester yarn, using mechanical double-covered yarn technology.

[0025] 3. Special yarn for weaving the toe surface: one piece of 40D spandex yarn as the core material and one piece of 150D hot-melt yarn, and the transition thread is woven by mechanical single-covered yarn technology, and the transition thread is combined with three pieces of 150D polyester yarn Air-covered yarn is used to weave special yarn for shoe toe surface.

[0026] 4. According to the pre-programmed pattern of the flat knitting machine, weave the special yarn for the heel, the special yarn for the middle surface of the sh...

Embodiment 2

[0039] A method for manufacturing an integrated horizontally knitted shoe upper, comprising the following steps:

[0040] 1. Special yarn for weaving shoe heels: 1 piece of 75D hot-melt yarn and 2 pieces of 150D polyester yarn, using air-covered yarn technology.

[0041] 2. Special yarn for weaving the middle surface of shoes: one 210D spandex yarn as the core material and one 150D polyester yarn, using mechanical double-covered yarn technology.

[0042] 3. Special yarn for weaving the toe surface: one piece of 40D spandex yarn as the core material and one piece of 100D hot-melt yarn, and the transition thread is woven by mechanical single-covered yarn technology, and the transition thread is combined with two pieces of 150D polyester yarn Air-covered yarn is used to weave special yarn for shoe toe surface.

[0043] 4. According to the pre-programmed pattern of the flat knitting machine, weave the special yarn for the heel, the special yarn for the middle surface of the shoe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com