Mixing reaction granulation all-in-one machine and method and application of granulation

An all-in-one machine and granulation technology, applied in mixers, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve the problems of uneven mixing, small processing capacity, and difficult to seal, and achieve a reasonable overall structure design. , the effect of uniform mixing and simple granulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

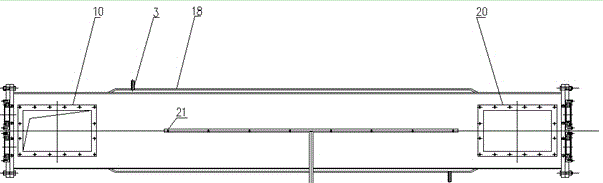

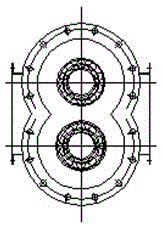

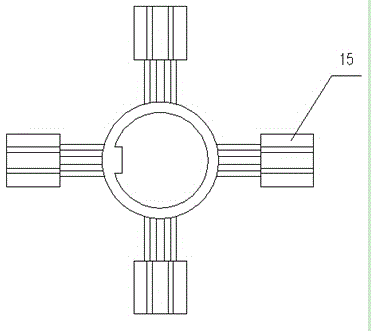

[0032] Reference attached figure 1 , a mixing reaction granulation integrated machine, a motor 1, a reducer 2, a differential 5, a housing 9 and a mixing and kneading mechanism; the housing 9 has an inlet 10 and an outlet 20, and the housing 9 has two The end is connected to the flange cover 6 by bolts; the mixing and kneading mechanism has two auxiliary transmission shafts arranged in parallel on the housing 9 through the bearing 7, and the junction of the two auxiliary transmission shafts and the two ends of the housing 9 is provided with a mechanical seal or a packing seal. The sealing structure 8, and the two auxiliary transmission shaft ends are connected with the differential 5, and the reducer 2 equipped with the motor 1 is connected to the differential 5 through the main transmission shaft 3; the two auxiliary transmission shafts include the feeding section from front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com