Cylinder circular seam simply and automatically welding arm

An automatic welding and circular seam technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low efficiency and quality of manual welding, and achieve a wide market development space, high efficiency, and high welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

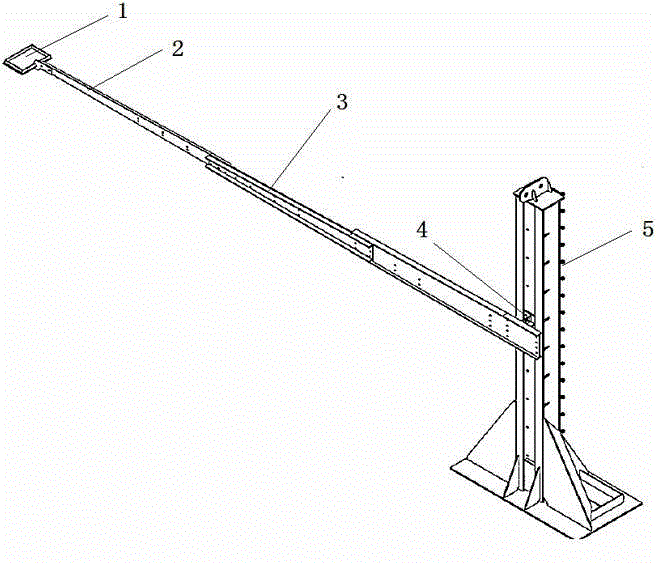

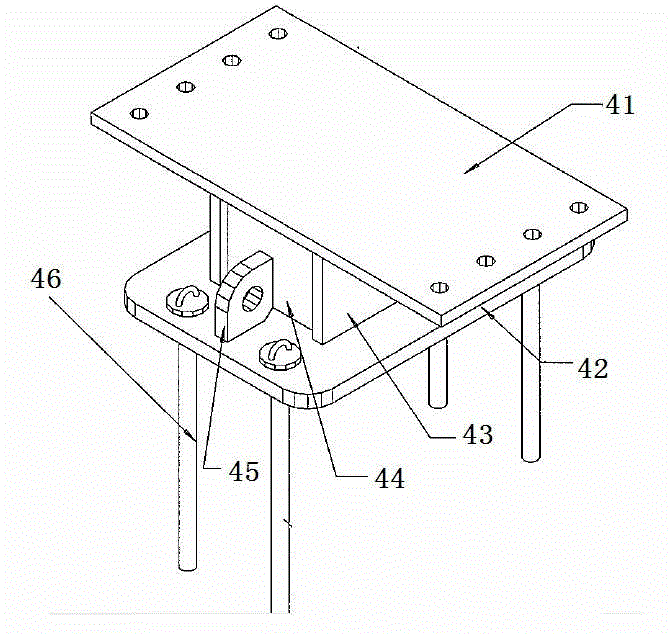

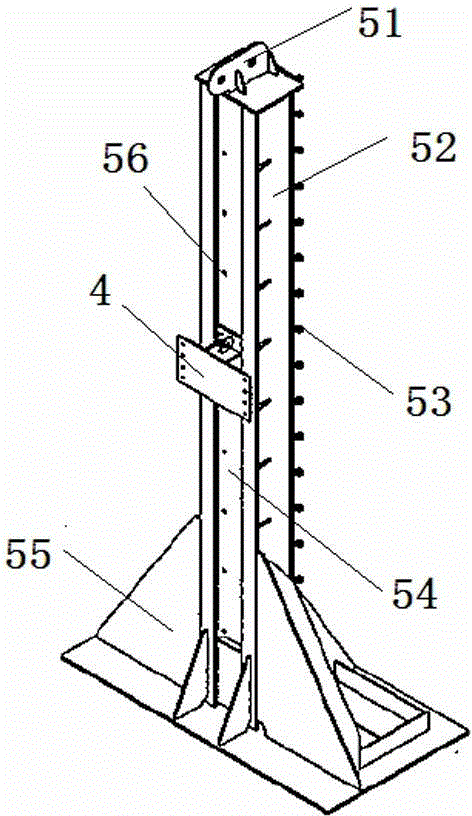

[0017] A simple automatic welding arm for the circumferential seam of a cylinder, including a welding machine platform 1, a front support arm 2, a combined support arm 3, a connector 4, a fixing seat 5, a heating ring 6, a vertical support 7, a horizontal support 8, and a reinforcing rib 9 , connecting plate 41, base plate 42, horizontal plate 43, vertical plate 44, lug 45, inserting rod 46, ring 51, square tube 52, pull ring 53, groove 54, base plate 55 and mounting hole 56, the fixed seat 5 The combined support arm 3 is installed through the connector 4, the combined support arm 3 is composed of multiple sections, and the required length is assembled according to actual needs, the front support arm 2 is installed on the combined support arm 3, and the front support arm 2 is installed with The welding machine platform 1, the front support arm 2 is cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com