Clamping fixture for externally threaded workpieces

A technology of workpiece clamping and external thread, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of difficult positioning accuracy and low production efficiency, and achieve the effect of solving the difficult control of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

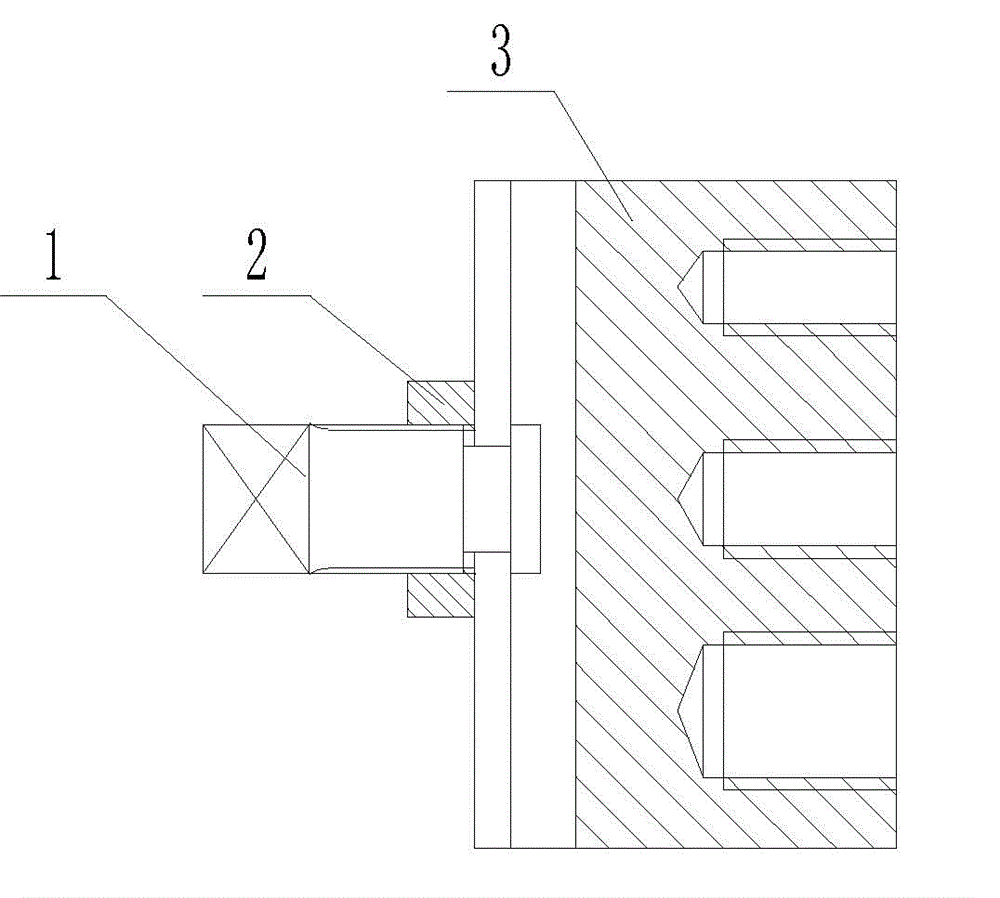

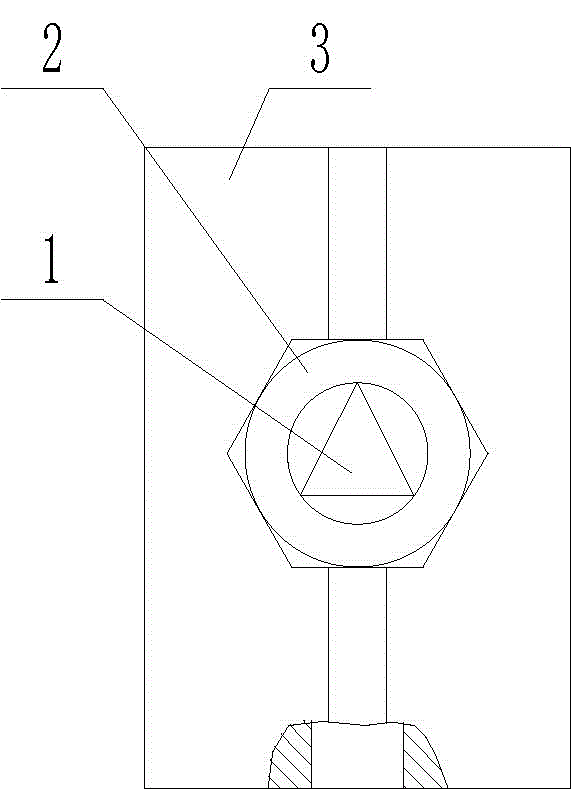

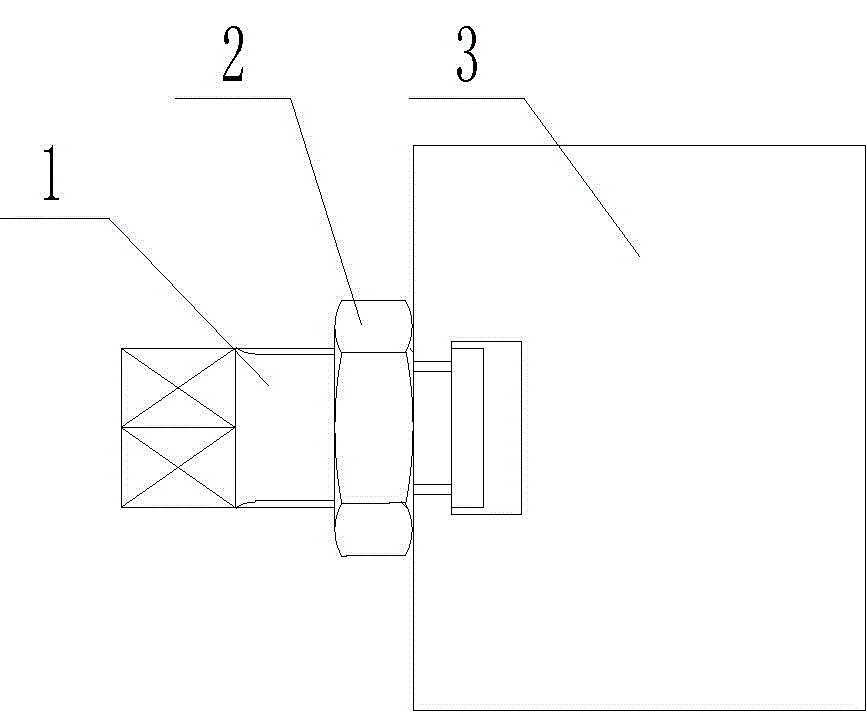

[0017] Embodiment one is basically as attached figure 1 , figure 2 , image 3 Shown: the external thread workpiece clamping fixture, including the rotating shaft 1, the lock nut 2 and the clamping plate 3, the rotating shaft 1 and the clamping plate 3 are detachably connected, the rotating shaft 1 and the locking nut 2 are threaded; the rotating shaft 1 From left to right, there are clamping part, threaded part, shaft neck and stop part; the clamping part is cylindrical, and there are three clamping surfaces on the clamping part, the crotch is disc-shaped, and the threaded part and The diameters of the blocking parts are the same, and the diameter of the shaft neck is smaller than that of the threaded part. The threads of the threaded portion match the threads of the lock nut 2 . The clamping plate 3 is a cuboid, and the front of the clamping plate 3 is provided with three longitudinally arranged threaded blind holes, and the three threaded blind holes are M8, M12, M24 on ...

Embodiment 2

[0022] The difference between the second embodiment and the first embodiment is that the stop part of the rotating shaft 1 is a dovetail block, and the chute is a dovetail groove matching the dovetail block.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap