Special jig for relieving and grinding the clearance angle of chamfering tools on cylindrical grinders

A technology for cylindrical grinding machines and special fixtures, which is applied in the direction of manufacturing tools, grinding workpiece supports, and other manufacturing equipment/tools. It can solve the problems of short tool life, rough machined surface, and low equipment utilization, and achieve equipment utilization. The effect of low efficiency, extended service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

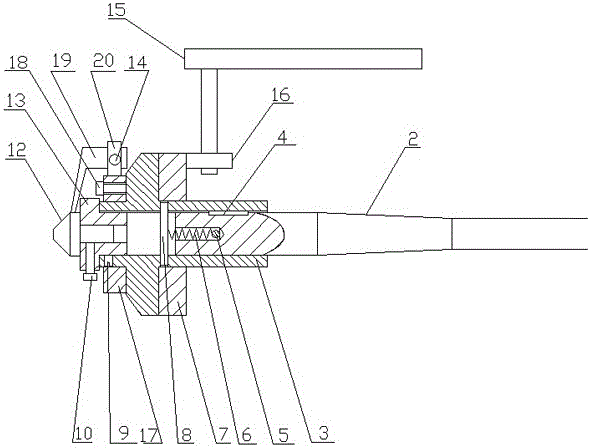

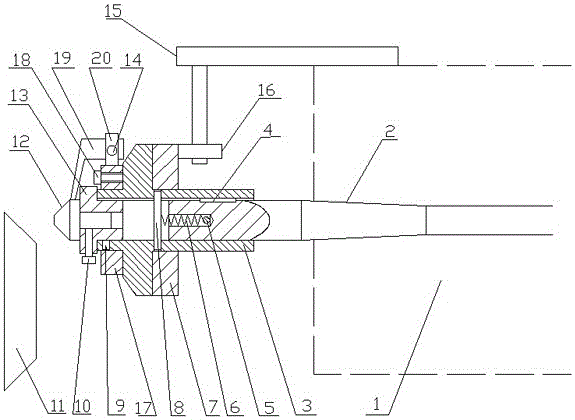

[0025] The specific implementation, structure, features and functions of the special jig proposed according to the present invention for shoveling the back corner of a chamfering knife on a cylindrical grinder are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0026] see figure 1 , the special fixture for relief grinding the back angle of the chamfering knife on the cylindrical grinder of the present invention includes a Morse taper shank sliding shaft 2, an axial cam 7, and an adjustment member 14, wherein: the end of the Morse taper shank sliding shaft 2 A sliding sleeve 3 is installed, and a guide key 4 is provided between the Morse taper shank sliding shaft 2 and the sliding sleeve 3. The axial cam 7 is fixed on the sliding sleeve 3, and the replaceable workpiece sleeve 13 is fixed on the end of the sliding sleeve 3. , the chamfering knife 12 is installed in the inner hole of the replaceable workpiece sleeve 13; the Mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com