High-speed conveying system of high-speed precise paper cutting machine

A technology of conveying system and paper cutting machine, which is applied in the direction of sending objects, transportation and packaging, thin material processing, etc., which can solve the problems of high cost and maintenance cost, high operating noise, and low uniformity of cutting edges, so as to ensure safety Conveying, reducing manufacturing cost, and saving conveying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Figure 1 to Figure 12 An embodiment of the invention is shown.

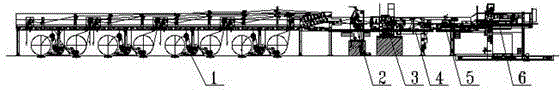

[0030] Such as figure 1 Shown: The high-speed precision paper cutter includes 1-unwinding frame system, 2-slitting system, 3-cross-cutting system, 4-high-speed conveying system, 5-folding system, 6-stacking system. 4- The role of the high-speed conveying system is to ensure that the paper web is conveyed smoothly during the production process and smoothly enters the stacking area in an accelerated manner.

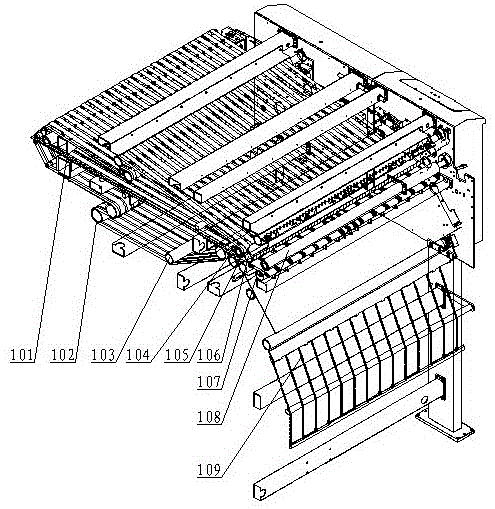

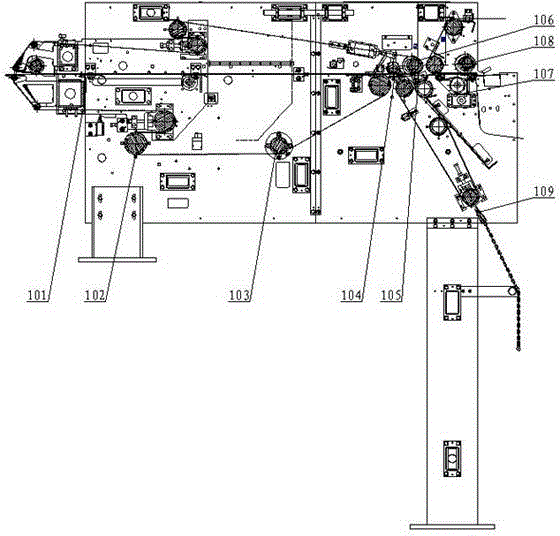

[0031] Such as figure 2 , image 3Shown: The high-speed conveying system of the high-speed precision paper machine includes 101-paper receiving trolley, 102-driving device, 103-tracting roller, 104-broken paper door device, 105-transporting platform, 106-regulating roller, 107-high-speed belt device , 108-pressure roller, 109-broken paper conveying device. When the cut paper web enters the 101-paper receiving trolley from the cross-cutting system, it will be clamped by the upper and lower belts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com