An anti-pilling finishing method for thick gauge brushed fabric

A coarse gauge, anti-pilling technology, applied in the direction of fabric kneading/softening, fabric surface trimming, heating/cooling fabric, etc., can solve the problem that the improvement of anti-pilling performance is not as good as that of chemicals, fabric feel and color fastness In order to improve the anti-pilling performance, reduce the probability of pilling, and increase the processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

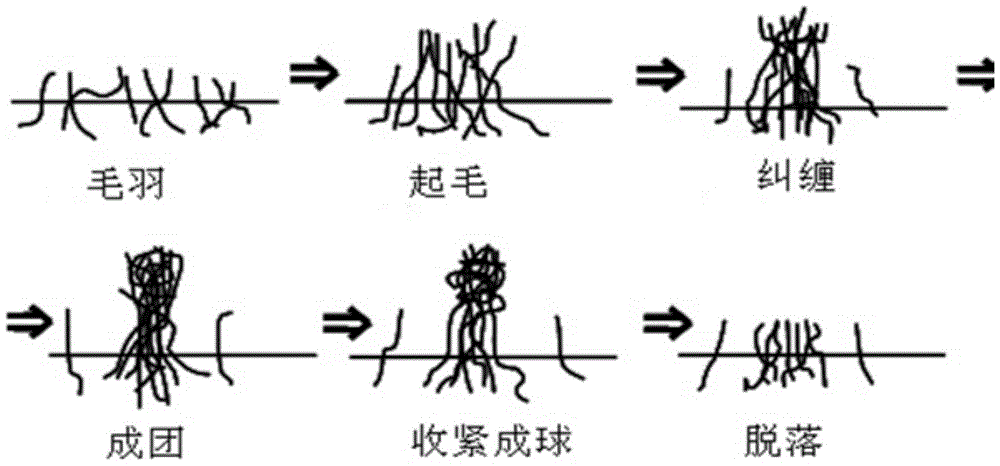

[0032] The physical method for improving the anti-pilling performance of the coarse-gauge fabric of the present invention includes processes such as napping, carding and shearing of the fabric. In the specific implementation of the present invention, the gray cloth used is the coarse gauge terry fabric produced by the coarse gauge loom. By changing the napping process, the fluff hidden between the fiber yarns is pulled out; by changing the carding process, the fluff pulled out is combed to make the fluff stand upright; by changing the shearing process, all the combed floating hairs are cut off, Reduces fuzz hidden between the yarns, thereby reducing the knots of fuzz pilling.

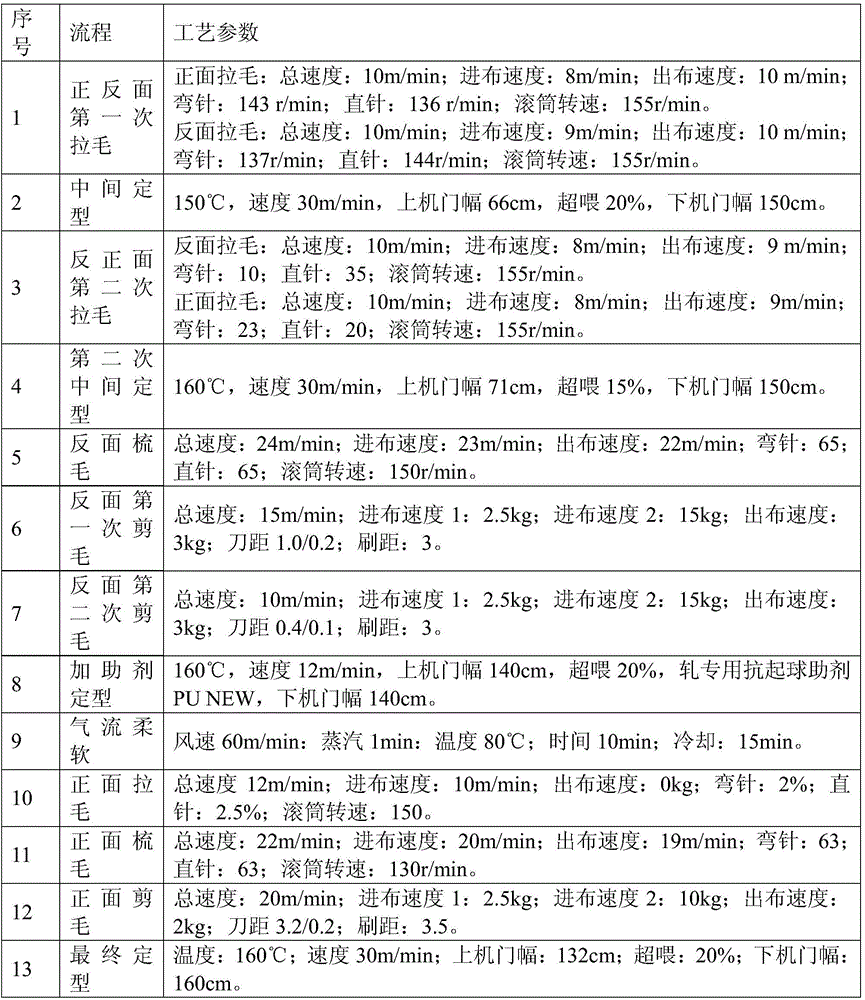

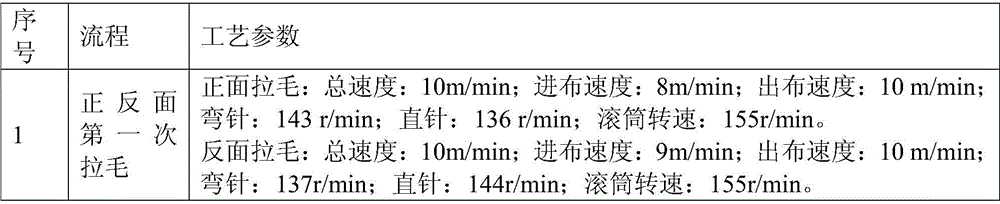

[0033] There is also a shaping process between the drawing, combing and shearing processes of the fabric. The specific process is as follows: the front and back are first pulled, the middle is shaped, the reverse is pulled for the second time, the middle is shaped, the back is combed, the back is sheare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com