Long wall coal mining roof pressure hydraulic support resistance change characteristic pre-warning method

A hydraulic support and resistance variable technology, applied in mining equipment, mining equipment, earthwork drilling and other directions, can solve problems such as poor accuracy and poor real-time performance, and achieve the effect of preventing adverse effects, predicting in time, and ensuring life safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

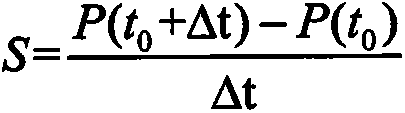

[0028] The method for early warning of the resistance change characteristics of the hydraulic support supported by the longwall mining roof of the coal mine uses the hydraulic support working resistance monitoring device, the pump station switch monitoring device and the hydraulic support resistance change index dynamic monitoring system to carry out early warning; the hydraulic support working resistance monitoring The device is used to record and store the monitored working resistance of the working face hydraulic support and the corresponding time in real time, and can transmit the stored data to the dynamic monitoring system of the hydraulic support resistance variable index; the pump station switch monitoring device is used to The monitored working face hydraulic support injection pump pressure end time is recorded and stored, and the stored data can be transmitted to the hydraulic support resistance change index dynamic monitoring system; the hydraulic support resistance c...

Embodiment 2

[0041] In this embodiment, the data recorded by each hydraulic support working resistance recorder is separately transmitted to the hydraulic support resistance change index dynamic monitoring system, and a resistance change index value is determined after numerical averaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com