Hydraulic system for stereoscopic garage

A technology of hydraulic system and three-dimensional garage, applied in the field of hydraulic system, can solve problems such as inability to perform power output, and achieve the effects of reducing frequent starts, avoiding injuries, and reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

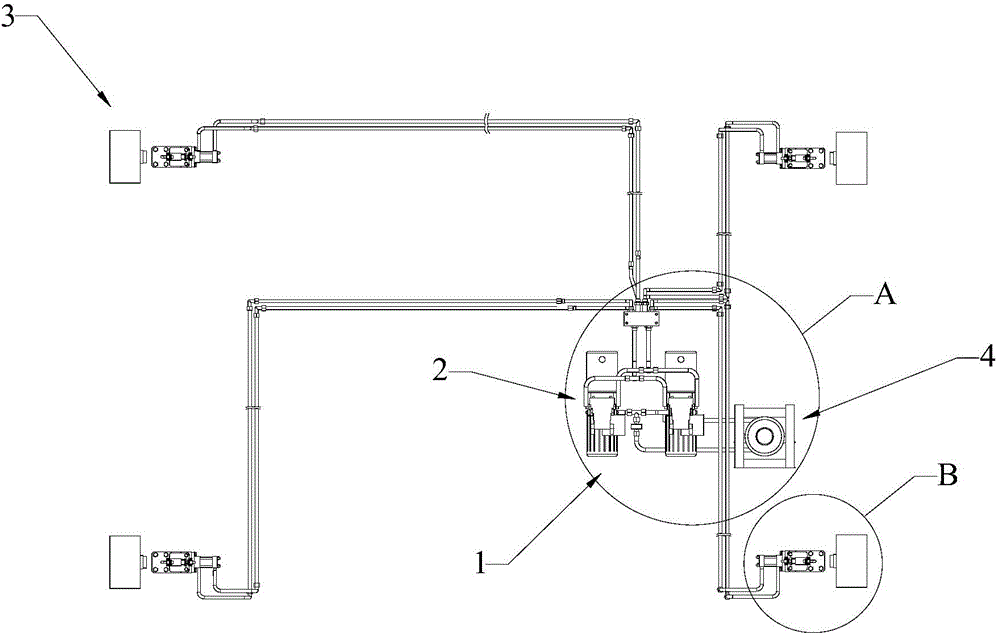

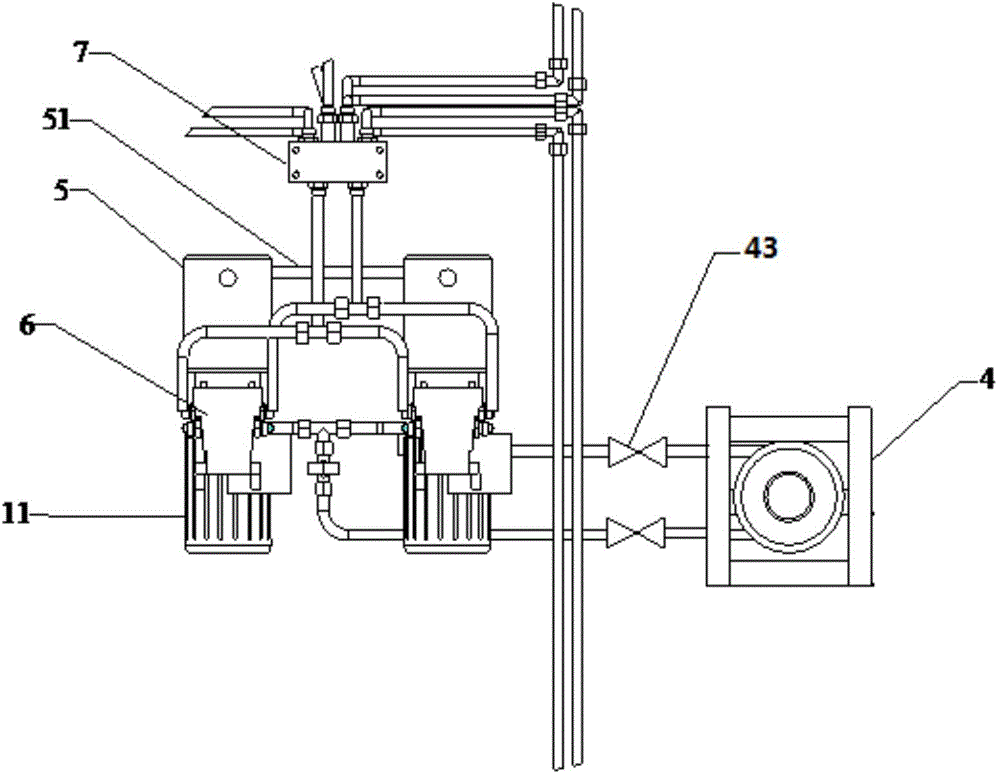

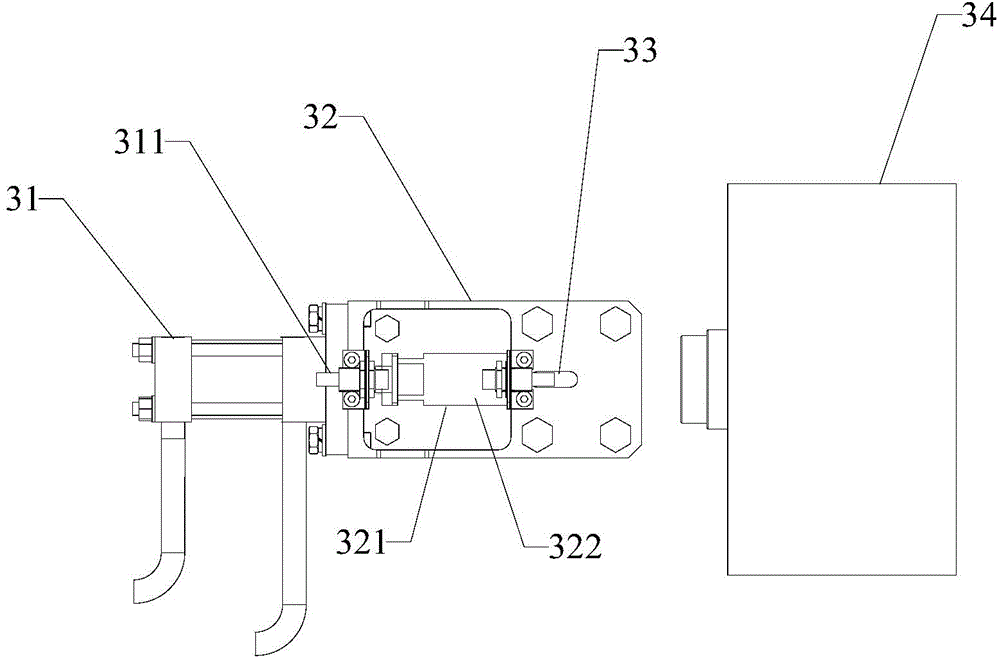

[0036] Please refer to Figure 1 to Figure 5 , Embodiment 1 of the present invention is:

[0037]A hydraulic system for a three-dimensional garage, including a motor oil pump 11, a fuel tank 5, a solenoid valve integration 6, an energy storage unit 4, an oil circuit block 7 and four execution units 3, the motor oil pump 11 is connected to the fuel tank 5, and the connection between the two fuel tanks 5 A fuel tank connecting pipe 51 is installed between them, and the fuel tank connecting pipe 51 communicates with the inner spaces of the two fuel tanks 5 . The energy storage unit 4 is connected to the outlet of the motor oil pump 11, connected to the solenoid valve assembly 6, and then divided into two pipelines to connect to the oil circuit block 7, and then diverted from the oil circuit block 7 to connect to each execution unit. The execution unit 3 includes a hydraulic cylinder 31, a support base 32, a positioning shaft 33 and a positioning sleeve 34. The support base 32 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com