Water supply line K-shaped joint with emergency self-recovery capability

A self-recovery, K-shaped technology, applied in the direction of pipe/pipe joint/pipe fitting, pipe element, sleeve/socket connection, etc., can solve the problems of water waste and untimely repair, so as to reduce water waste and reduce The effect of loss of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

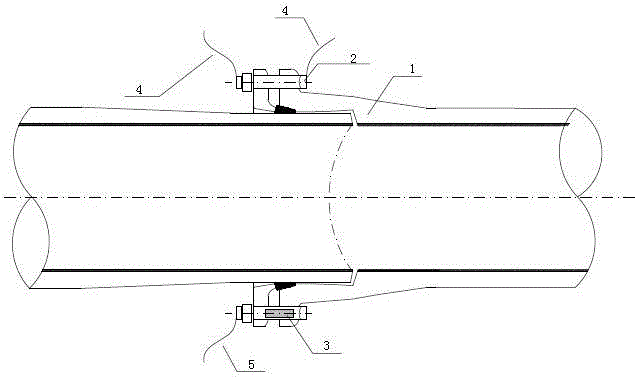

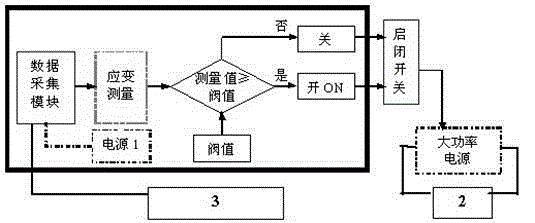

[0012] Example 1: Combining figure 1 , consists of K-shaped mechanical joint 1, shape memory alloy bolt 2, vibrating wire strain sensor 3, power line 4, data line 5 and data processing and emergency response integrated box 6. During installation, first insert the socket of the K-shaped mechanical joint 1 into the socket, and connect the K-shaped mechanical joint 1 with shape memory alloy bolts 2 . Install the vibrating wire strain sensor 3 on the shape memory alloy bolt 2 to measure the strain of the bolt. Then, two ends of the shape memory alloy bolt 2 are connected to the data processing and emergency response integration box 6 with two power lines 4;

[0013] With this device, the strain of the bolt can be monitored in real time. When the lower joint has a large deformation after the earthquake, the data processing and emergency response integration box monitors and finds that the bolt strain reaches a given maximum limit. The memory alloy bolts are energized and heated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com