Manufacturing shop operation adaptive scheduling method and device

A technology for production workshops and scheduling methods, applied in data processing applications, instruments, resources, etc., can solve problems such as incoordination, lag, and inconsistency, and achieve the effect of overcoming lag and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

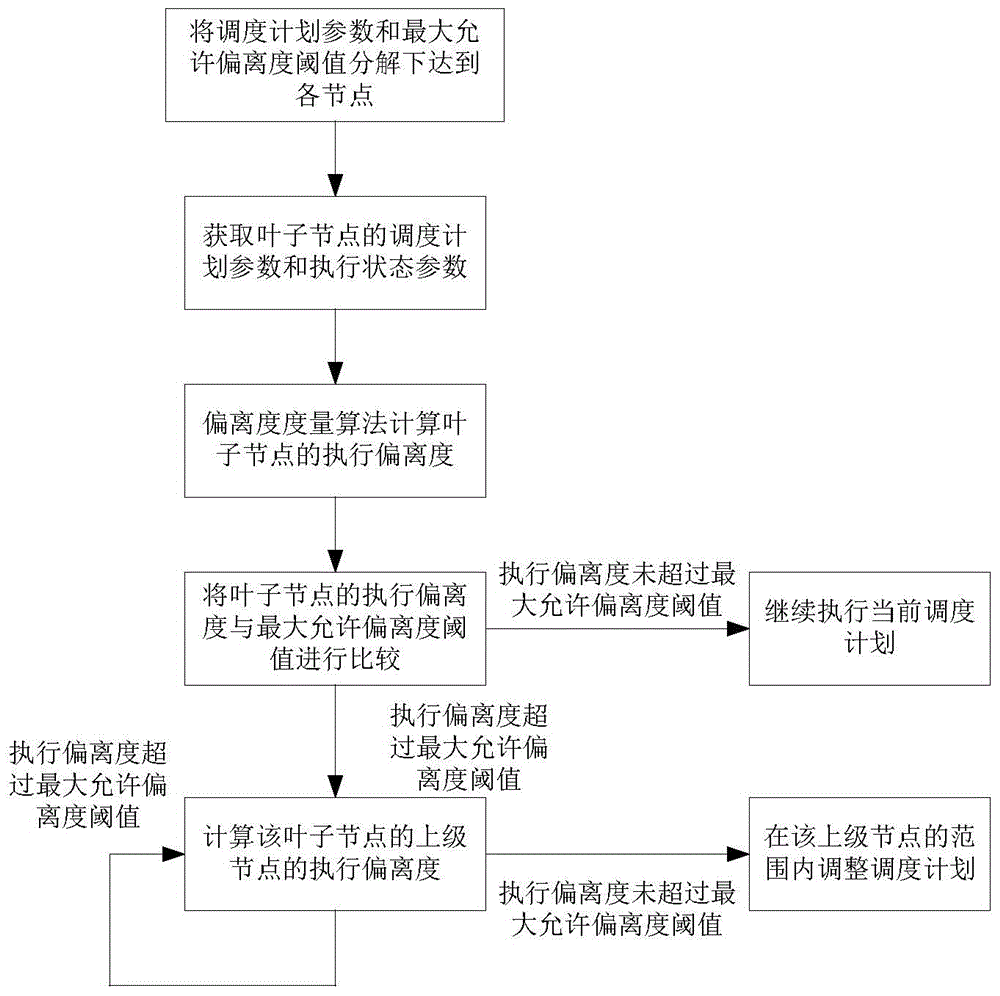

[0044] Such as figure 1 As shown, a method for adaptive scheduling of production workshop operations, the method includes the following steps:

[0045] S1: Divide the production workshop into a multi-layer tree structure, and decompose the scheduling plan parameters and the maximum allowable deviation threshold from top to bottom to reach each node;

[0046]S2: Obtain the scheduling plan parameters and execution status parameters of each leaf node, and calculate the execution deviation degree of each leaf node through the deviation degree measurement algorithm according to the scheduling plan parameters and execution status parameters of each leaf node;

[0047] S3: Compare the execution deviation of each leaf node with the maximum allowable deviation threshold of each leaf node, if the execution deviation does not exceed the maximum allowable deviation threshold, continue to execute the current scheduling plan, if the execution deviation exceeds the maximum allowable deviatio...

Embodiment 2

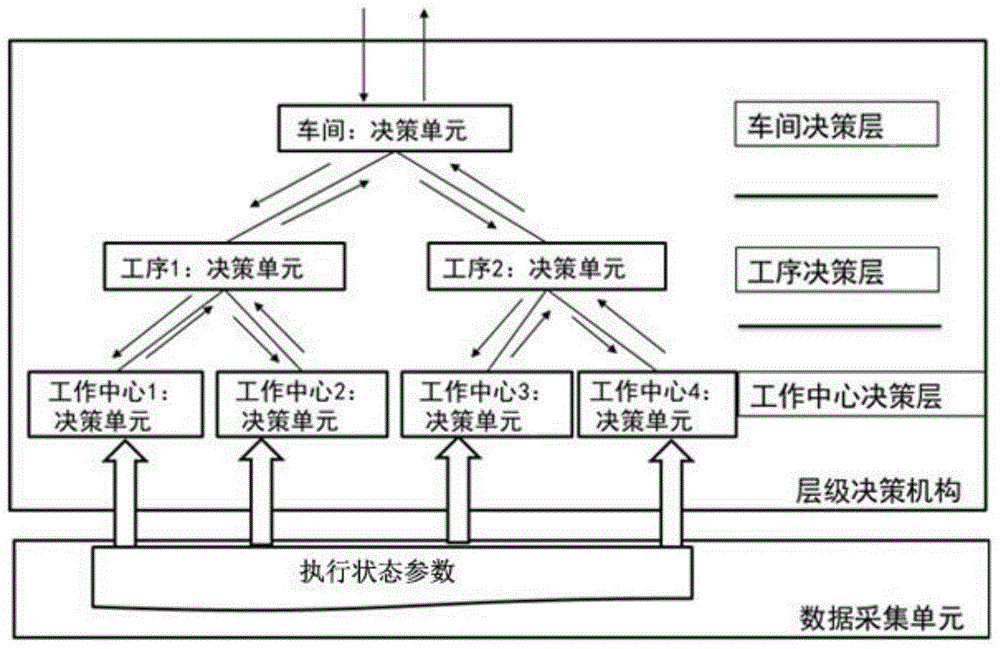

[0066] An adaptive scheduling device for production workshop operations, the device comprising:

[0067] Data collection unit: used to collect execution status parameters, and then send them to the hierarchical decision-making organization through the network;

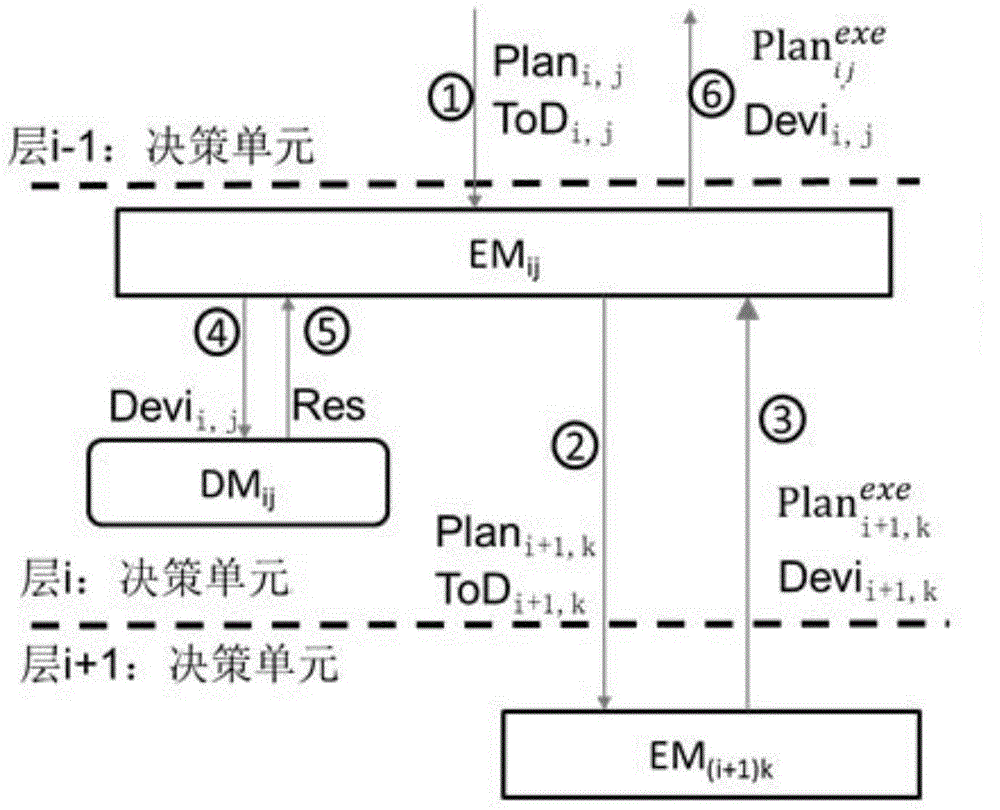

[0068] Hierarchical decision-making body: deployed on the enterprise server, used to calculate the execution deviation of each node layer by layer from bottom to top, and compare the execution deviation of each node with the maximum allowable deviation threshold of the node, and make a decision to continue to execute the current schedule Plan, adjust the scheduling plan within the scope of the node or feed back to the adaptive scheduling decision of the upper node;

[0069] Decision output unit: used to output the adaptive scheduling decision made by the hierarchical decision-making mechanism to the corresponding control device.

[0070] Such as figure 2 As shown, in the specific implementation process, the hierarch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com