Automatic evaluation and control method for quality risk in research and development process of power tool

A technology of heavy-duty machine tools and control methods, which is applied in the direction of data processing applications, instruments, resources, etc., can solve the problems of lack of standards such as scoring measurement standards, evaluation method risk ratings, high subjectivity in the review process, and unsatisfactory, so as to improve identification and control ability, improve the effect of science and correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

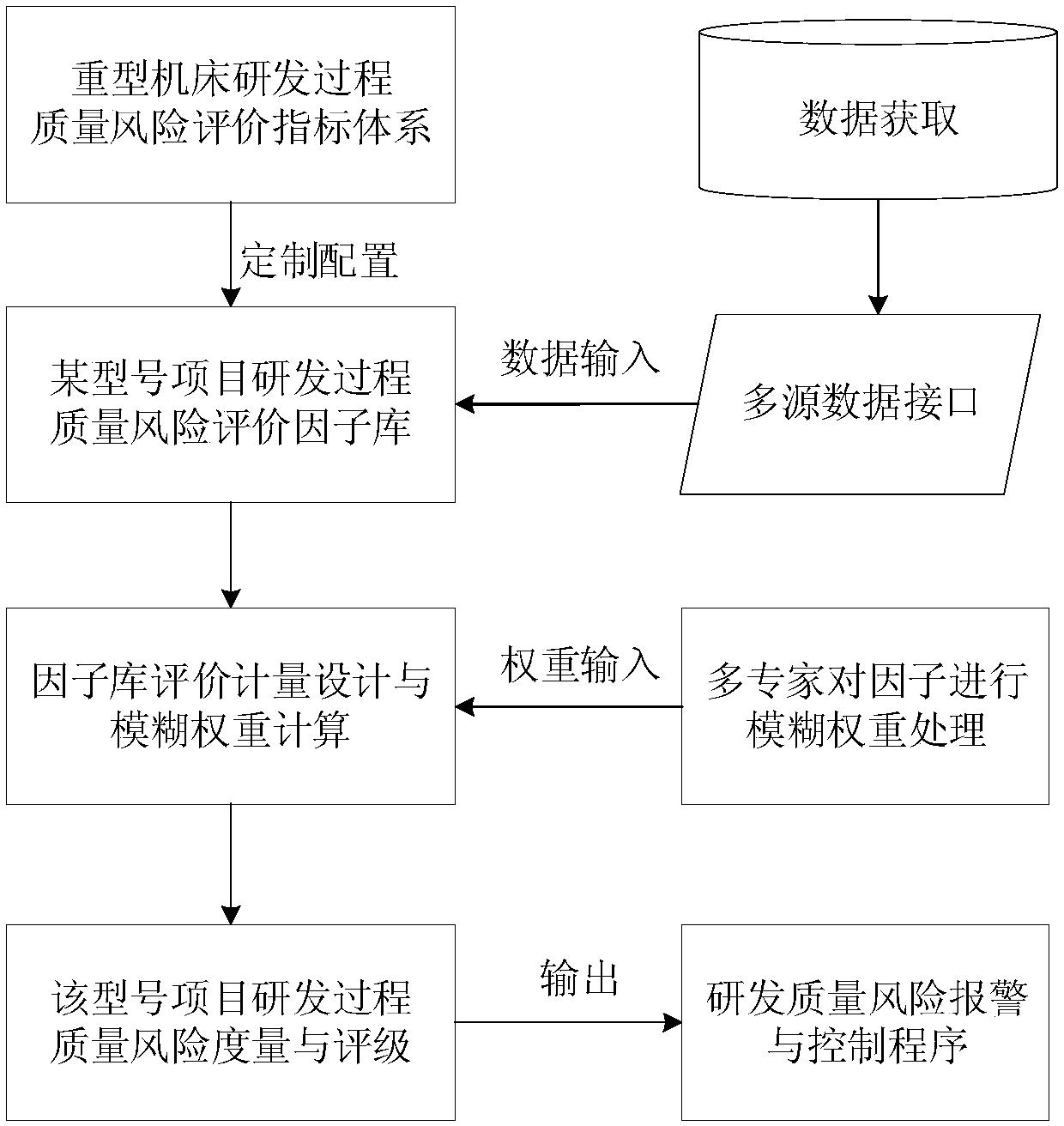

[0029] A method of quality control for heavy machine tools, see figure 1 , the quality control method includes the following steps:

[0030] 101: Construct an evaluation index system that reflects the quality risk of the heavy-duty machine tool research and development process. The system includes 8 first-level indicators and 40 second-level indicators;

[0031] Among them, the evaluation index system is constructed according to the characteristics and status quo of the R&D process of heavy-duty machine tools, and the requirements of heavy-duty machine tool enterprises for modern quality risk control in the R&D process.

[0032] 102: Use the data interface to connect with the information system of the research and development process of the heavy machine tool enterprise to realize the real-time collection of online data;

[0033] 103: According to the actual quality risk assessment requirements of R&D projects, customize and configure the required indicators from the indicato...

Embodiment 2

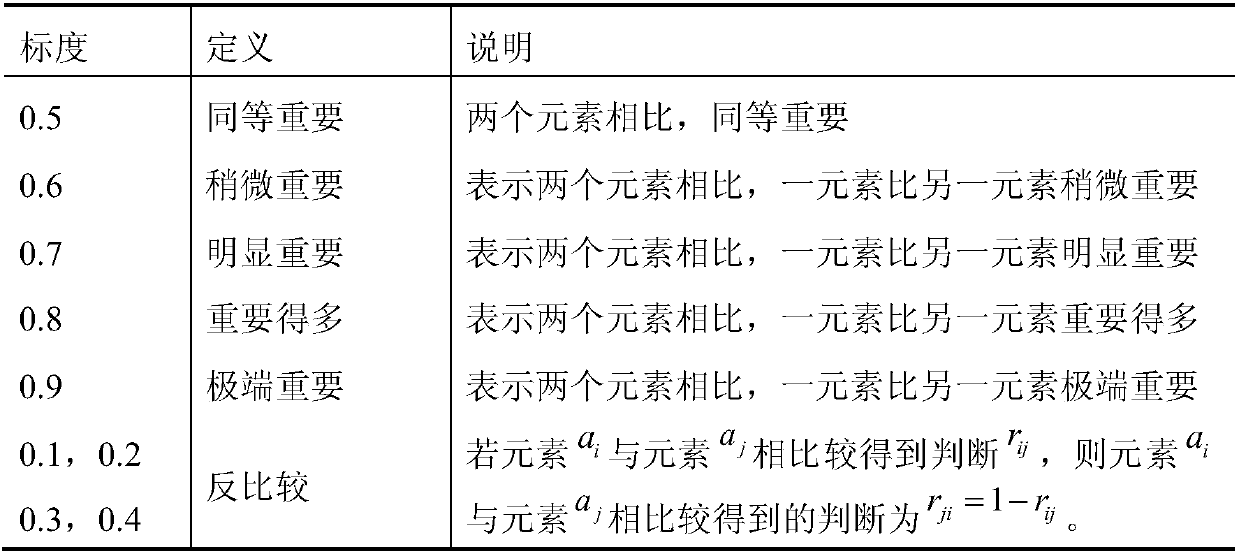

[0044] Combine below figure 1 , specific examples, and calculation formulas further introduce the scheme in Embodiment 1, see the following description for details:

[0045] 201: Build an evaluation index system that reflects the quality risk of the heavy machine tool R&D process, which includes 8 first-level indicators and 40 second-level indicators;

[0046] In the embodiment of the present invention, by investigating the quality characteristics of the research and development process of heavy-duty machine tools, combined with the characteristics of research and development of heavy-duty machine tools and the status quo of enterprise informatization, the embodiment of the present invention constructs the quality risk management index system structure of the research and development process of heavy-duty machine tools, involving eight categories X1 to X6 R&D process quality risk, 40 secondary indicators. By constructing a configurable quality risk management index system, th...

Embodiment 3

[0088] The following specific examples, figure 2 The scheme in embodiment 1 and 2 is carried out feasibility verification with experimental data, see the following description for details:

[0089] The embodiment of the present invention is the quality risk control of the research and development process of a CK-XXXX heavy-duty turning and milling machining center system of a certain enterprise. The quality risk management index system construction evaluation task of this method is used for configuration, and the enterprise information platform research and development process data corresponding to all indicators, Automatic collection, fusion, and processing are performed through the data interface to form a set of quality risk control factors for the CK-XXXX heavy-duty turning and milling machining center system R&D process for experts to evaluate the factor weights.

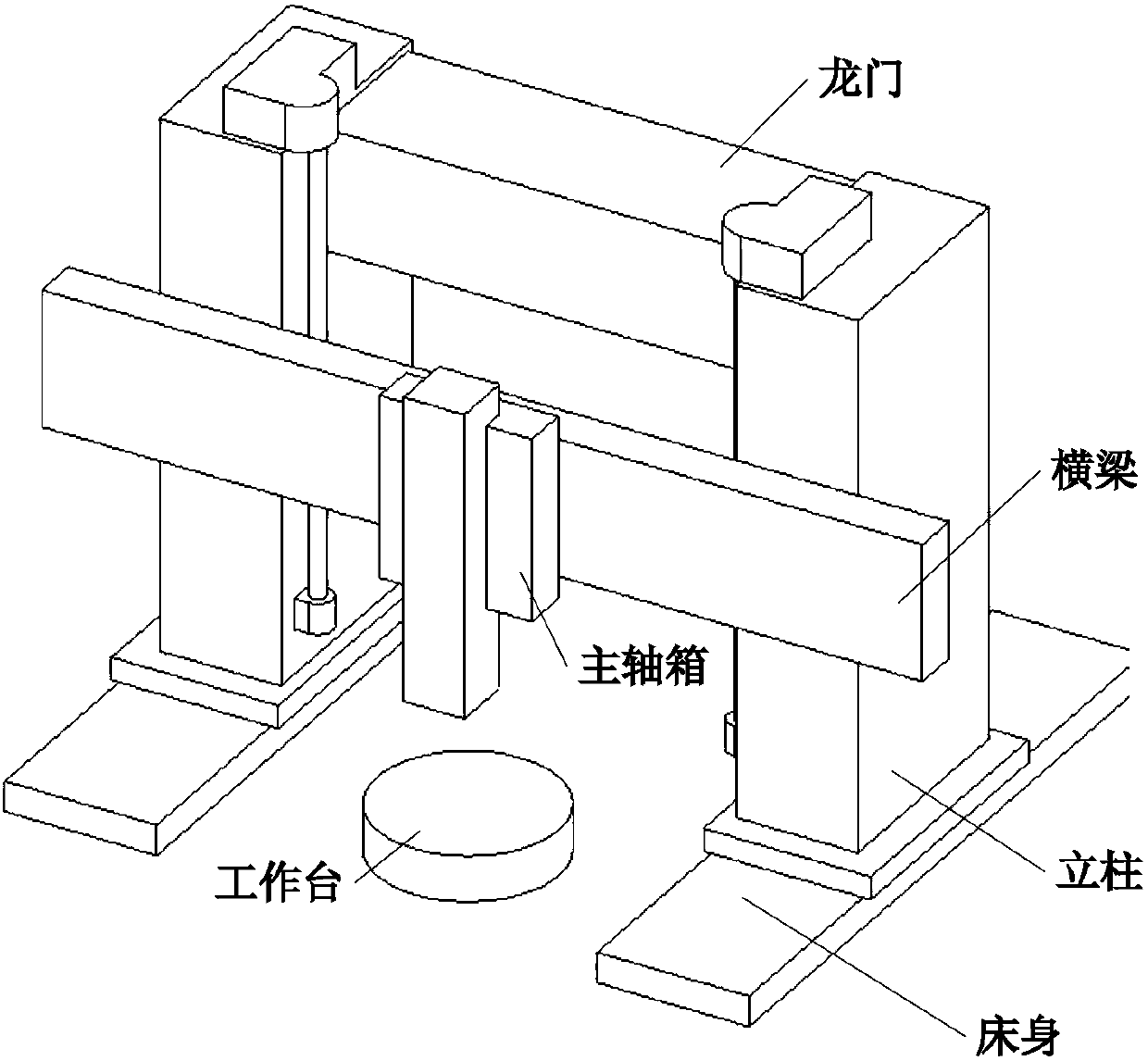

[0090] A CK-XXXX heavy-duty turning and milling machining center system includes: structural system, electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com