A tension-compression vibration energy harvester

A technology of energy harvesters and transducers, which is applied in the field of new energy and power generation, can solve problems such as low reliability and poor environmental adaptability, and achieve the effects of improving reliability, effective frequency bandwidth, and good low-frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

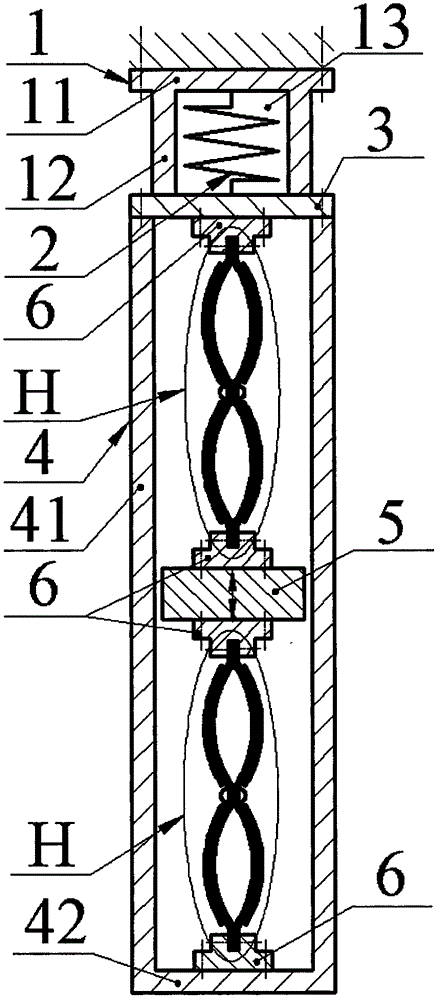

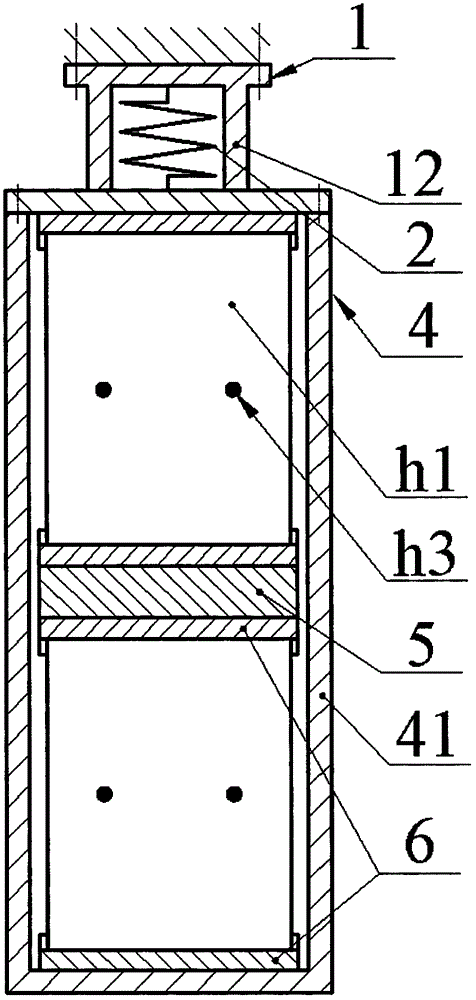

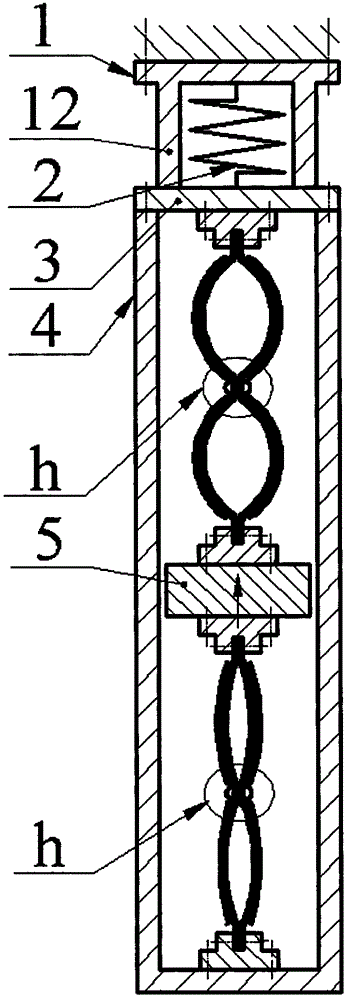

[0014] like Figure 1 to Figure 5 As shown, the upper wall 11 of the hanger 1 is fixed on the vibration main body through screws, and the upper wall 11 of the hanger 1 is fixed with a tension spring 2, and the extension spring 2 is enclosed in the inner cavity 13 of the hanger 1, and the lower end of the tension spring 2 Fixed on the cover plate 3, the cover plate 3 is in contact with the end face of the tube wall 12 of the hanger 1; In the inner cavity; two metal sheets h1 bonded with piezoelectric sheet h2 on their arc sections are riveted to each other by rivets h3 to form a piezoelectric vibrator h, and the piezoelectric vibrator h and the supports 6 riveted by rivets at both ends together form a replacement The upper and lower sides of the inertia block 5 are respectively connected with the supports 6 on the two transducers H by screws, and the other support 6 of the transducer H above the inertia block 5 is fixed on the cover plate by screws 3, another support 6 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com