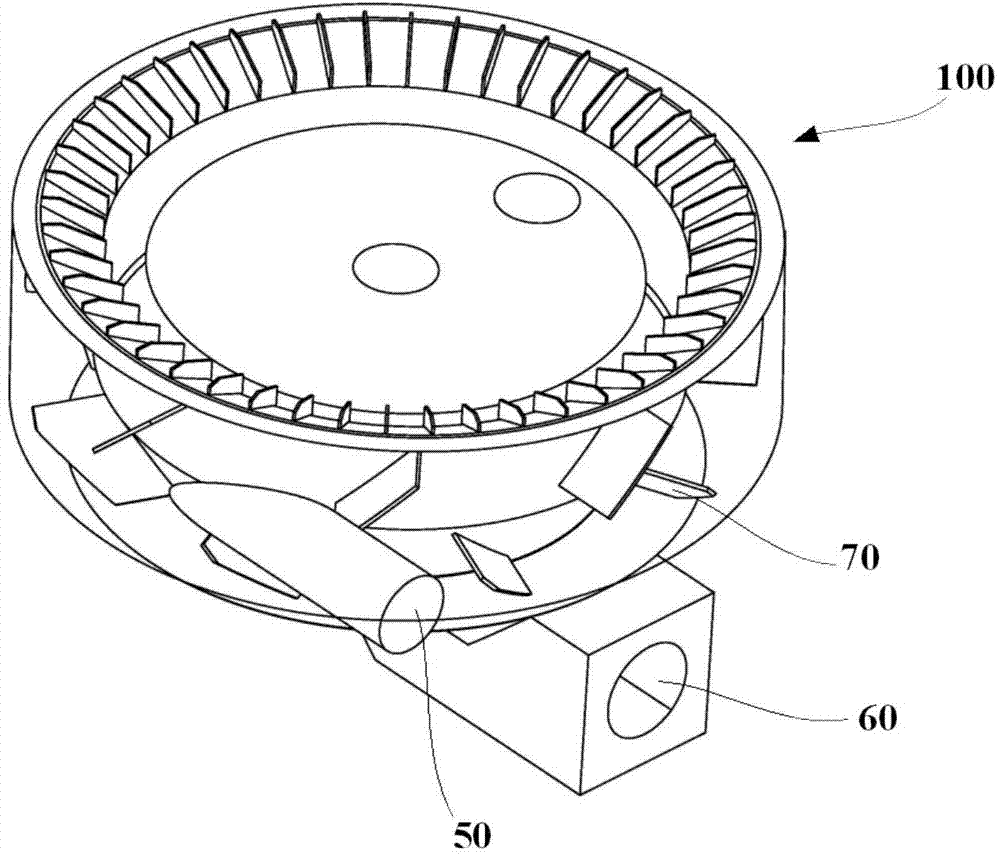

Fracturing blender tank, fracturing blender truck and fracturing truck unit

A sand mixing tank and tank body technology, applied in mixers, mixers with rotary stirring devices, dissolution and other directions, can solve the problems of poor fracturing fluid uniformity, high stirring energy consumption, and affecting fracturing quality, etc. The effect of improving fracturing quality and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

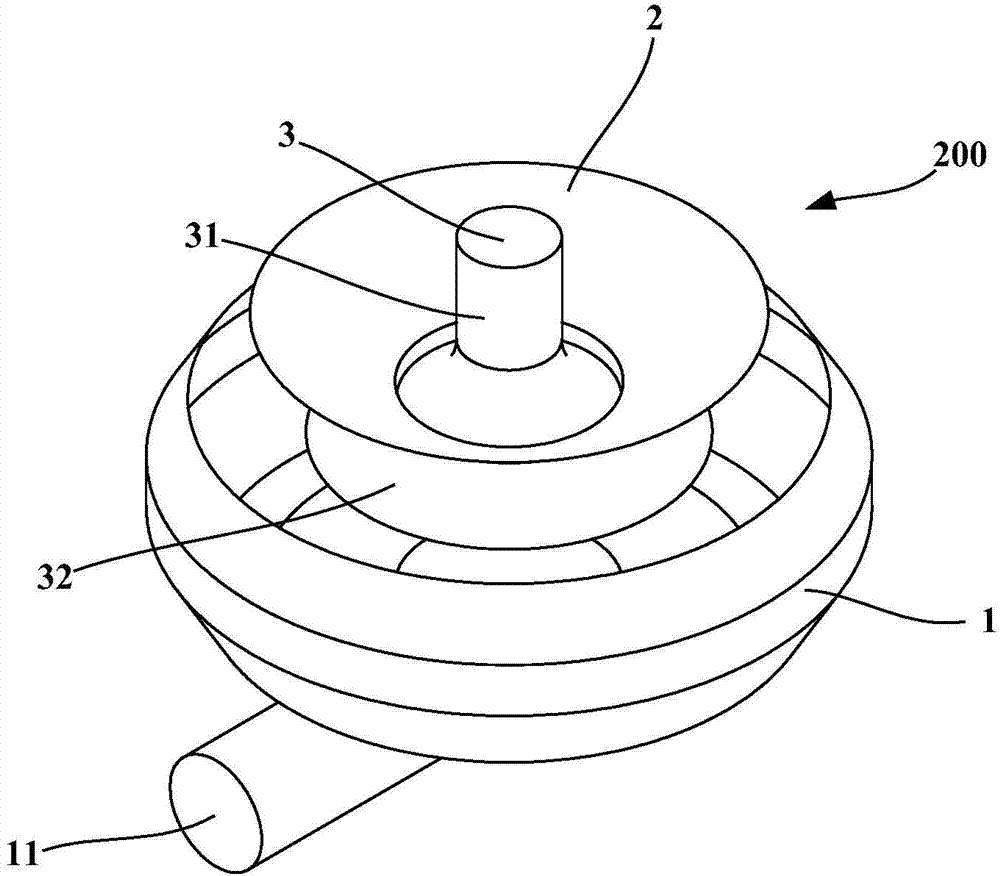

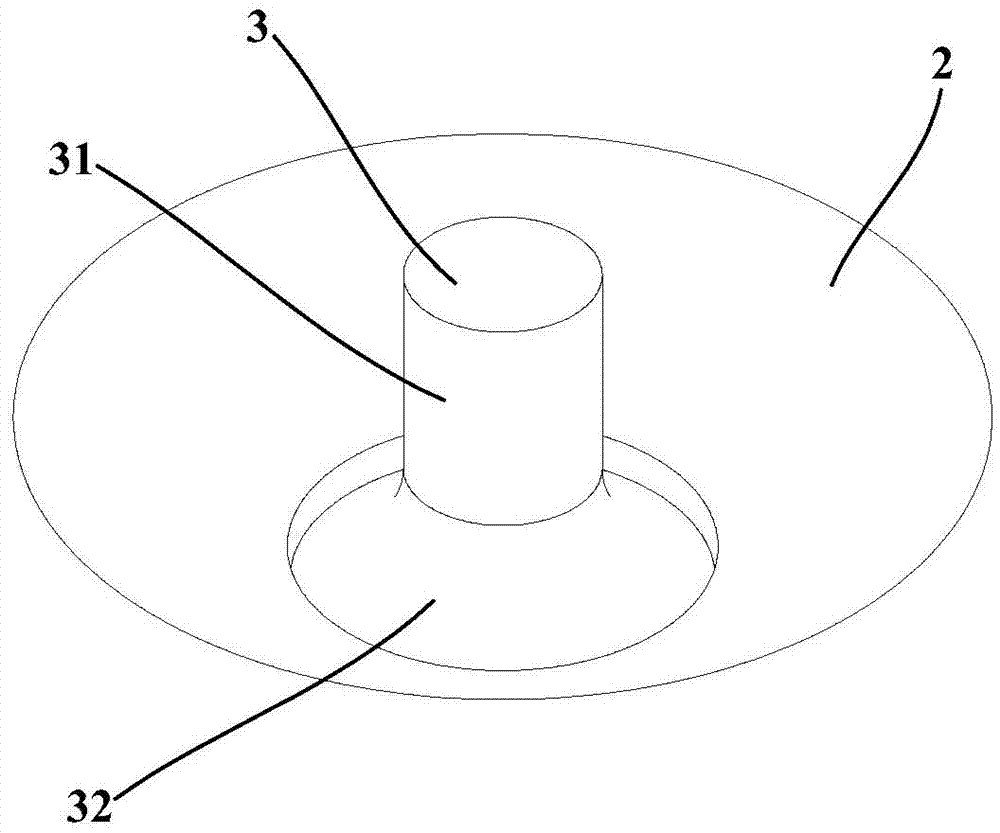

[0042] In order to improve the uniformity of the fracturing fluid, improve the quality of fracturing, and reduce the energy consumption of the equipment, the embodiment of the present invention provides a sand mixing tank, a sand mixing truck and a fracturing train unit. The present invention will be described in detail below with specific embodiments and in conjunction with the accompanying drawings.

[0043] The sand mixing tank provided by the first embodiment of the present invention includes a tank body, a leakage plate, an inlet pipe and a lower plate arranged coaxially arranged in the tank body in sequence from top to bottom, wherein: the top of the tank body is open, and the bottom has The fracturing fluid outlet; the inlet pipe includes a nozzle and a flared portion, the bottom opening of the leaky plate pierced by the nozzle protrudes upwards, and there is a gap between the flared portion and the bottom opening of the leaky plate; between the lower plate and the flare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com