Double-line palm closing type reinforcement bar straightening mechanism and double-line palm closing type reinforcement bar straightening machine

A steel bar and fitting technology, which is applied in the field of the new double-wire palm-joining steel bar straightening machine, can solve the problems of needing improvement in efficiency, overall structure, and imperfect action, and achieve consistent amplitude, fast and effective straightening process, and consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

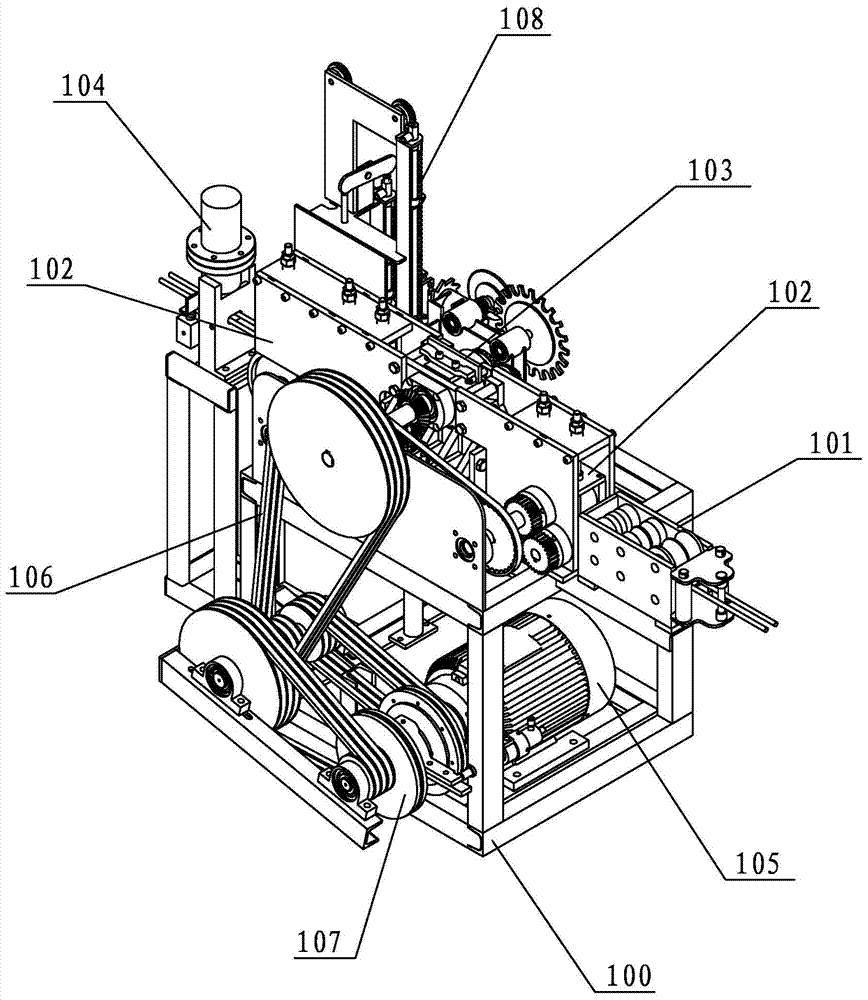

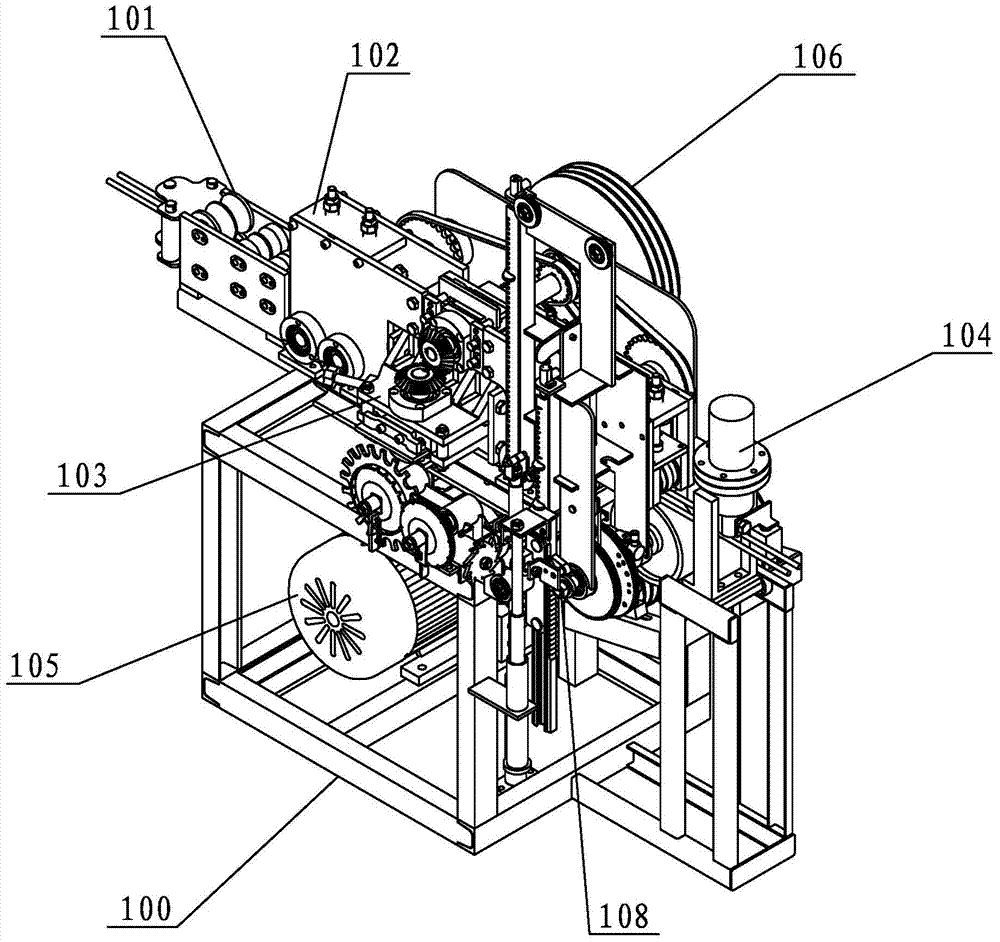

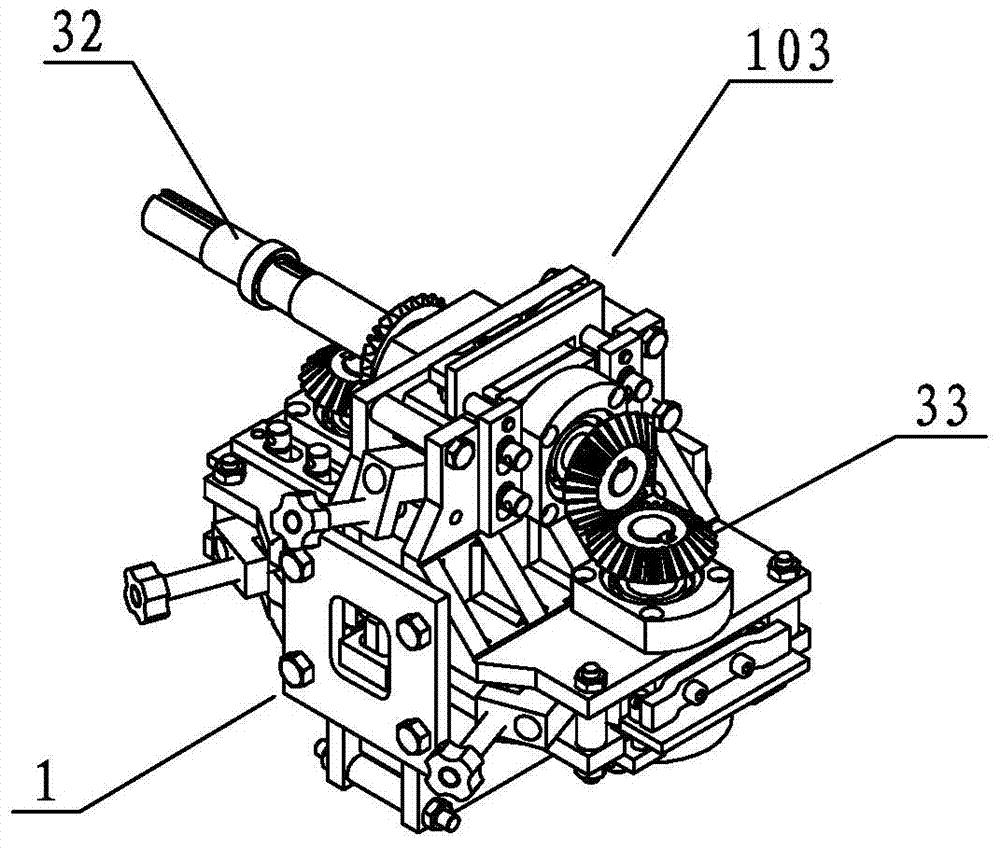

[0032] Reference figure 1 , figure 2 , The new dual-line palm-fitting steel bar straightening machine provided by the present invention includes a frame 100 on which a guide mechanism 101, a feeding mechanism 102, a dual-line palm-fitting steel bar straightening mechanism 103 and a cutting mechanism 104 are provided. The guiding mechanism 101, the feeding mechanism 102, the double-line palm-closing steel bar straightening mechanism 103, and the cutting mechanism 104 are arranged in sequence along the advancement direction of the steel bars. Among them, two feeding mechanisms 102 are provided, which are distributed in the double-line palm-closing steel bar straightening mechanism 103. Front and back. The frame 100 is also provided with a driving motor 105 that drives the feeding mechanism 102 and the double-line palm-closing steel bar straightening mechanism 103. The drive motor 105 connects the feeding mechanism 102 and the double-line palm-closing steel bar straightening mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com