A press-fit steel bar straightening machine

A press-fitting and straightening machine technology, applied in the field of steel bar processing, can solve the problems of the overall structure and unfinished movements, and achieve the effect of fast and effective straightening process, ensuring consistency and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

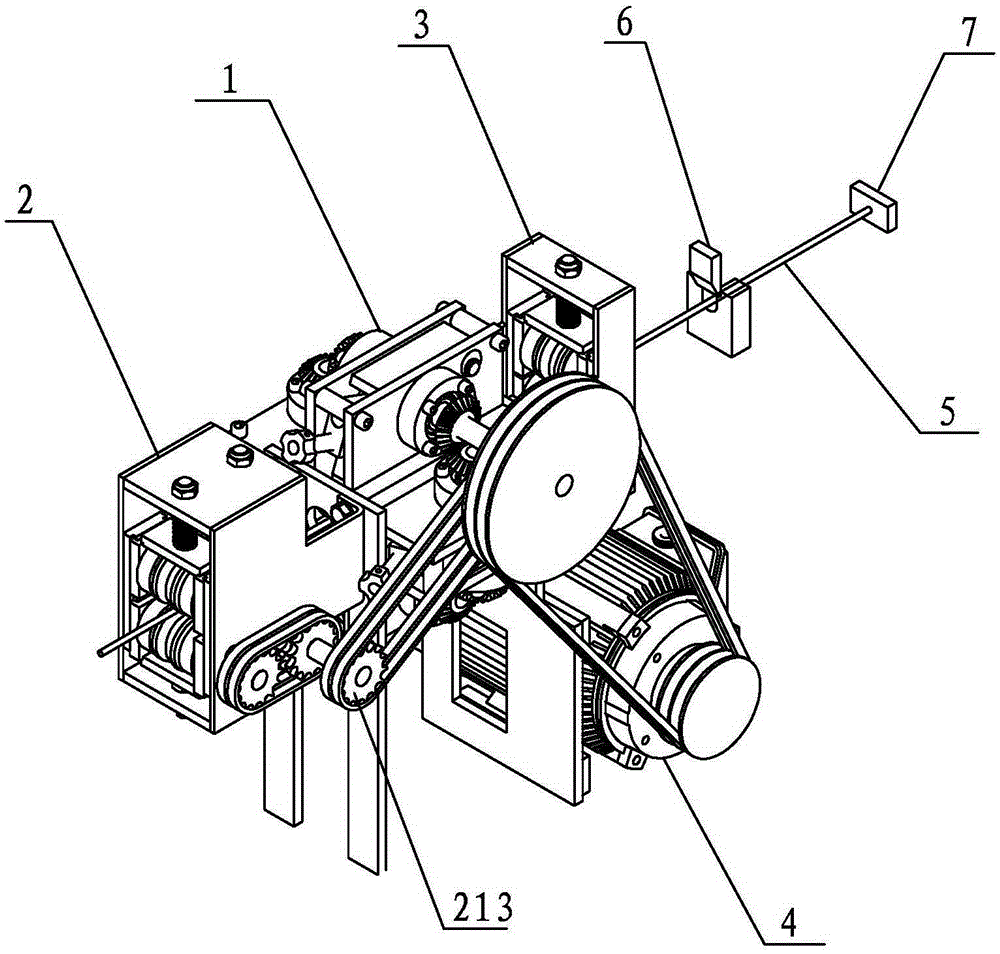

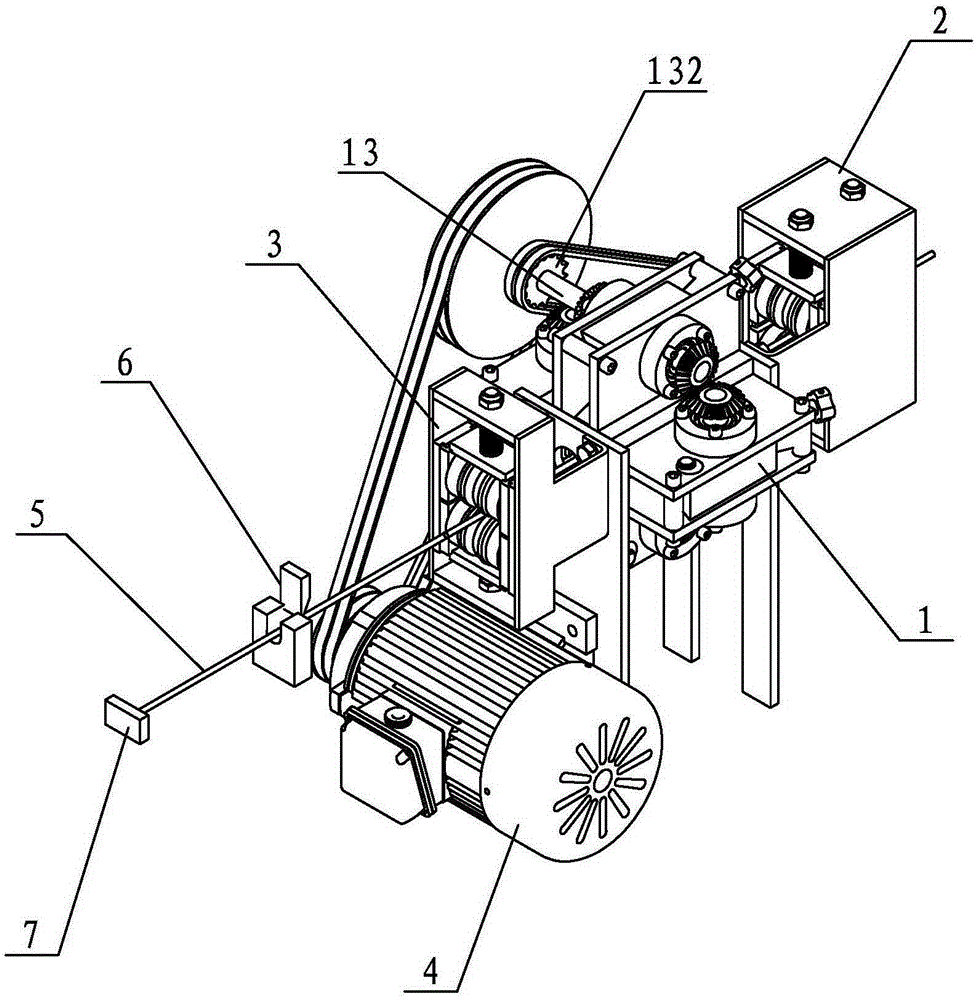

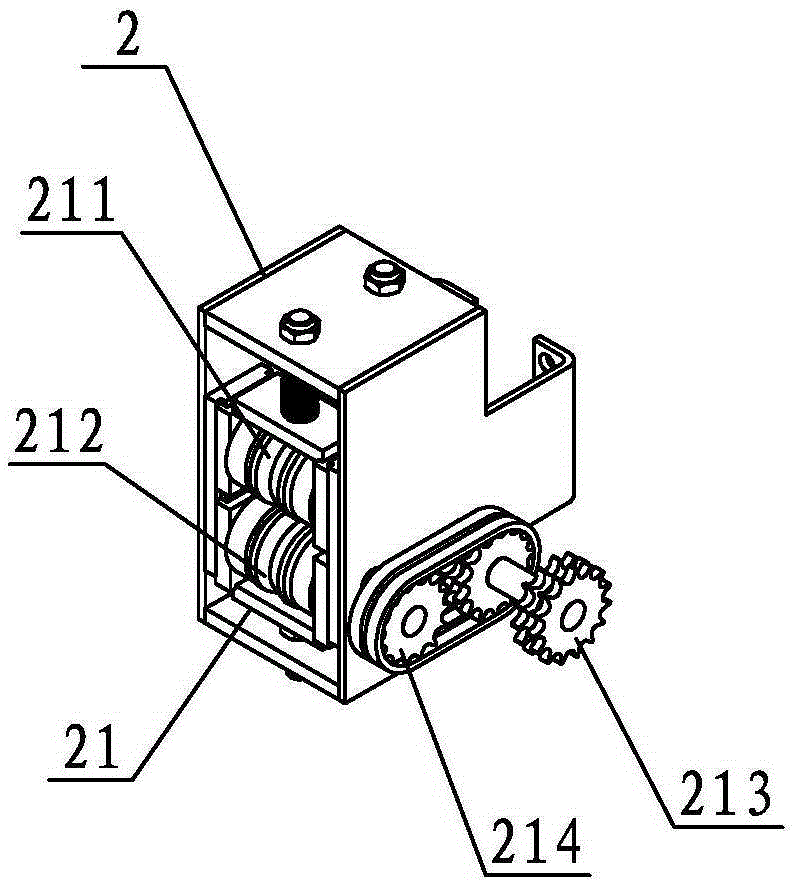

[0035] The press-fit type steel bar straightening machine of the present invention will be described in further detail below with reference to the accompanying drawings.

[0036] refer to figure 1 , figure 2 , a preferred embodiment of the press-fit type steel bar straightening machine provided by the present invention, the press-fit type steel bar straightening machine includes a guide mechanism 2, a press-fit type straightening mechanism 1 and a lead-out mechanism 3 arranged in sequence along the advancing direction of the steel bar 5. In this embodiment, the lead-in mechanism 2 is connected to the driving device for driving the steel bar 5 forward. The lead-in mechanism 2 and the lead-out mechanism 3 cooperate with each other to guide the steel bar 5, so that the steel bar 5 passes through the press-fit adjustment in a roughly straight line. The straightening mechanism 1, and at the same time, the press-fit straightening mechanism 1 performs intermittent squeezing and str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com