Vehicle and glide feedback control method thereof

A control method and technology of coasting feedback torque, which are applied in the directions of road vehicle drive control systems, control devices, vehicle components, etc., can solve the problems of not fully considering the driver's experience of maximizing energy feedback and a single deceleration curve, and improving energy efficiency. Feedback efficiency, improve driving range, simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

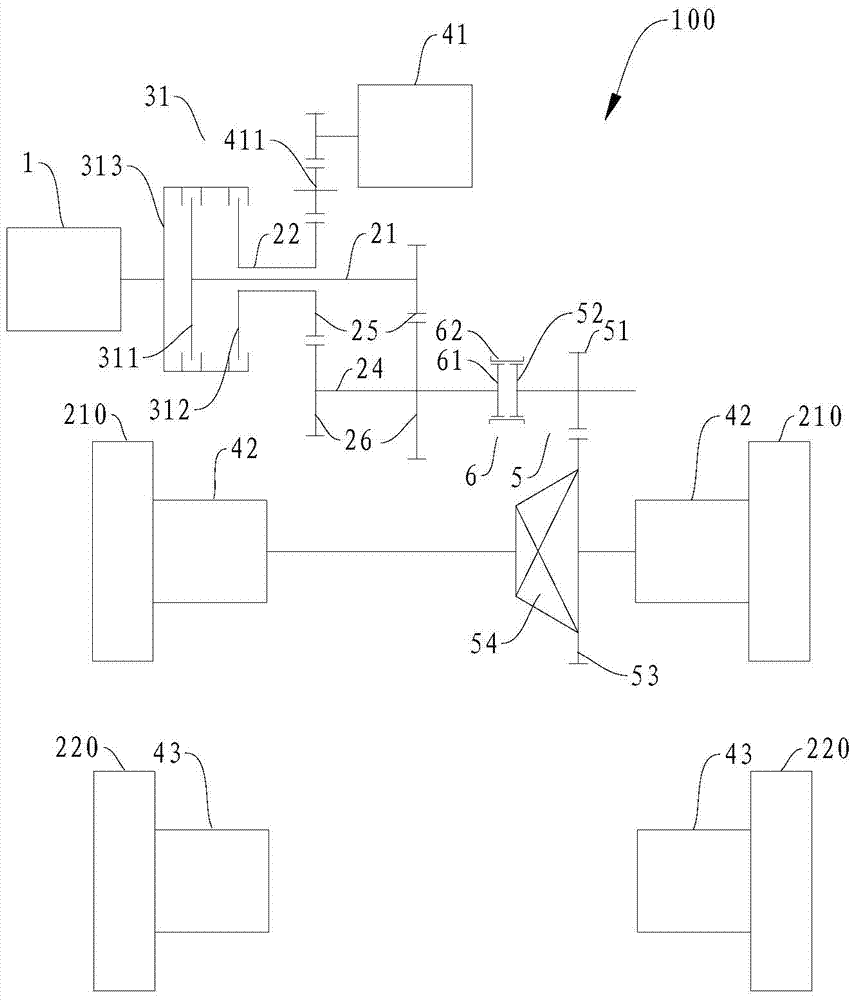

[0158] like figure 2 As shown, the engine unit 1 is connected to the input end 313 of the double clutch 31, the first output end 311 of the double clutch 31 is connected to the first input shaft 21, and the second output end 312 of the double clutch 31 is connected to the second input shaft 22, The second input shaft 22 is coaxially sleeved on the first input shaft 21 .

[0159] A driving gear 25 is fixedly arranged on the first input shaft 21 and the second input shaft 22 respectively, and the first motor generator 41 is indirectly driven with the driving gear 25 on the second input shaft 22 through an intermediate gear 411 . Two driven gears 26 are fixedly arranged on the output shaft 24 , and the two driven gears 26 respectively mesh with the driving gears 25 on the first input shaft 21 and the second input shaft 22 to form two transmission gears.

[0160] The synchronizer 6 is arranged on the output shaft 24, and the driving gear of the main reducer (that is, the output ...

Embodiment 2

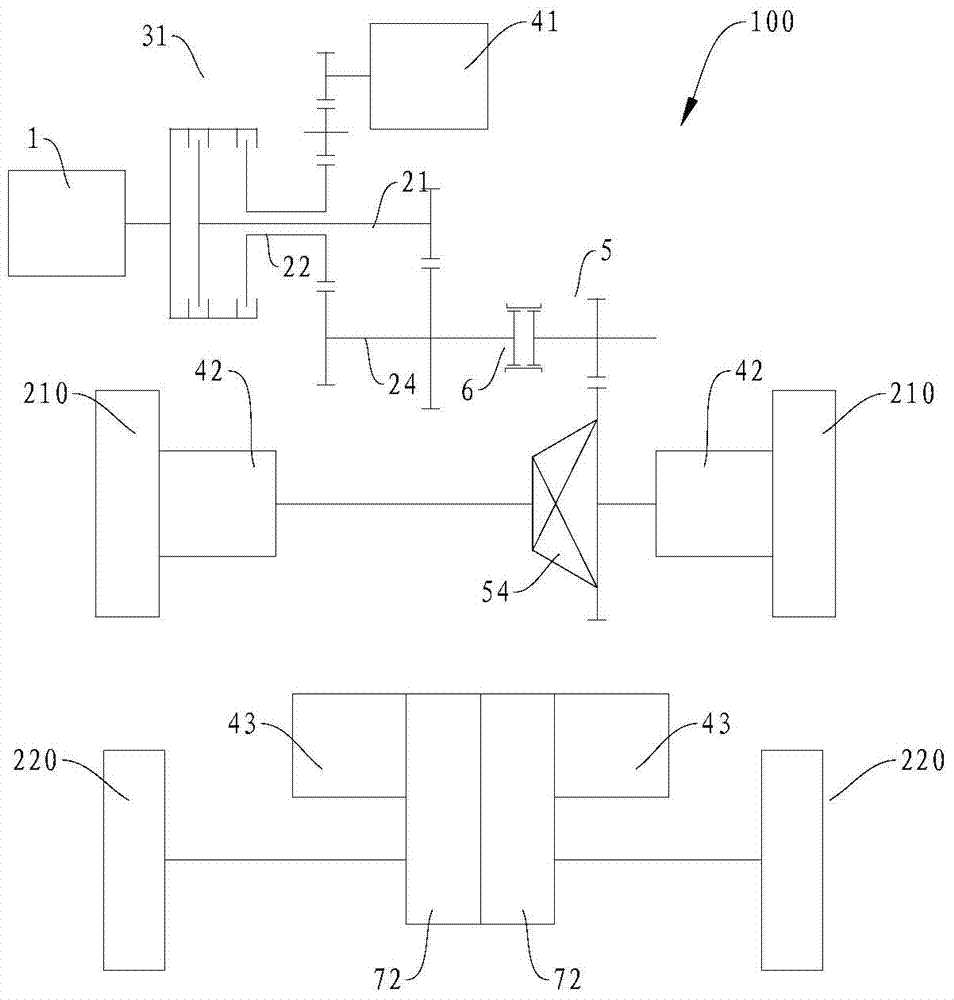

[0188] like image 3 As shown, the power transmission system 100 in this embodiment and figure 2 The difference of the power transmission system 100 in the above may only lie in the arrangement form of the second motor generator 43 . In this embodiment, each second motor-generator 43 drives the corresponding rear wheel 220 through a second speed change mechanism 72, and the remaining parts can be connected with figure 2 The power transmission system 100 in the embodiment is basically the same, and will not be repeated here. As for the specific working conditions, it is related to figure 2 The power transmission system 100 in the embodiment is basically the same, and the only difference is that the power transmission between the second motor generator 43 and the corresponding rear wheel 220 needs to go through the second transmission mechanism 72 , which will not be described in detail here.

Embodiment 3

[0190] like Figure 4 As shown, the power transmission system 100 in this embodiment and figure 2 The difference of the power transmission system 100 in the above may only lie in the arrangement form of the second motor generator 43 . In this embodiment, the second motor-generator 43 is one and drives the corresponding rear wheel 220 through a first speed change mechanism 71, and the remaining parts can be connected with figure 2 The power transmission system 100 in the embodiment is basically the same, and will not be repeated here. As for the specific working conditions, it is related to figure 2 The power transmission system 100 in the embodiment is basically the same, and the only difference is that the two rear wheels 220 are driven by a second motor-generator 43 and a first speed change mechanism 71, so without adding new components, only The differential function of the two rear wheels 220 cannot be realized by a motor and a transmission mechanism, but it can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com