Container automatic overturning and opening-closing device for vertical waste compression station

A garbage compression station and automatic turning technology, which is applied in the direction of garbage collection, garbage transmission, storage devices, etc., can solve the high operating cost of the transfer station, and the danger of cumbersome operations such as unlocking, turning up and closing, and locking the feeding door of garbage containers to reduce operating costs, avoid complexity, and simplify operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing.

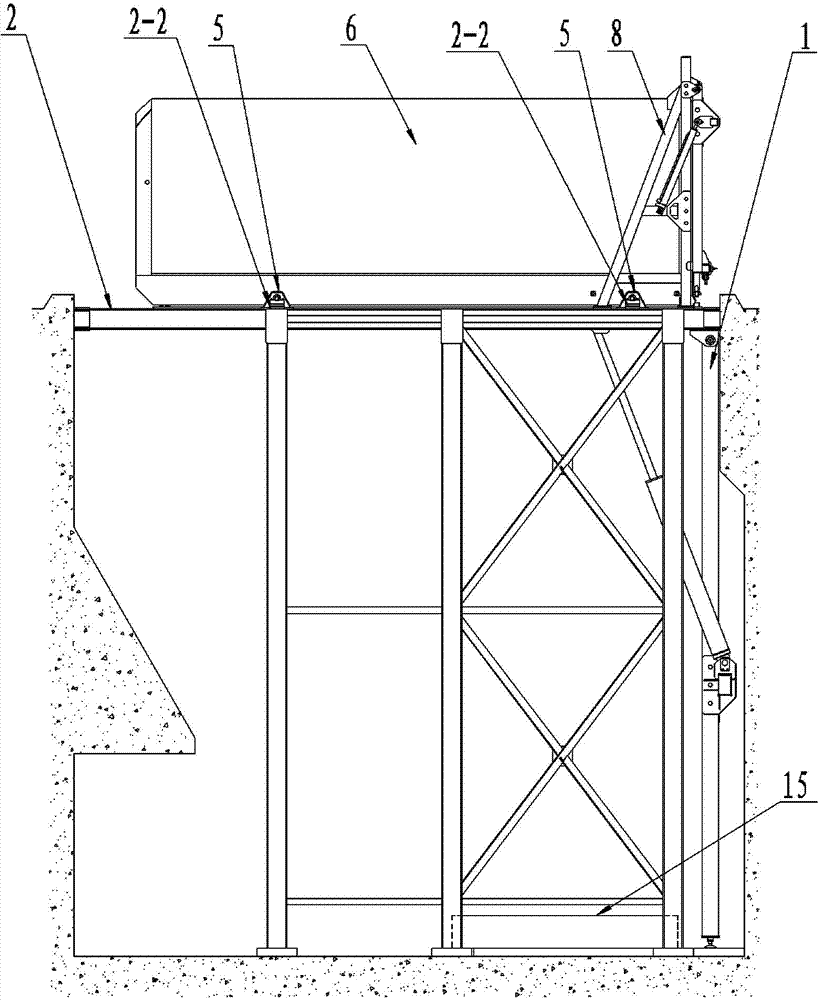

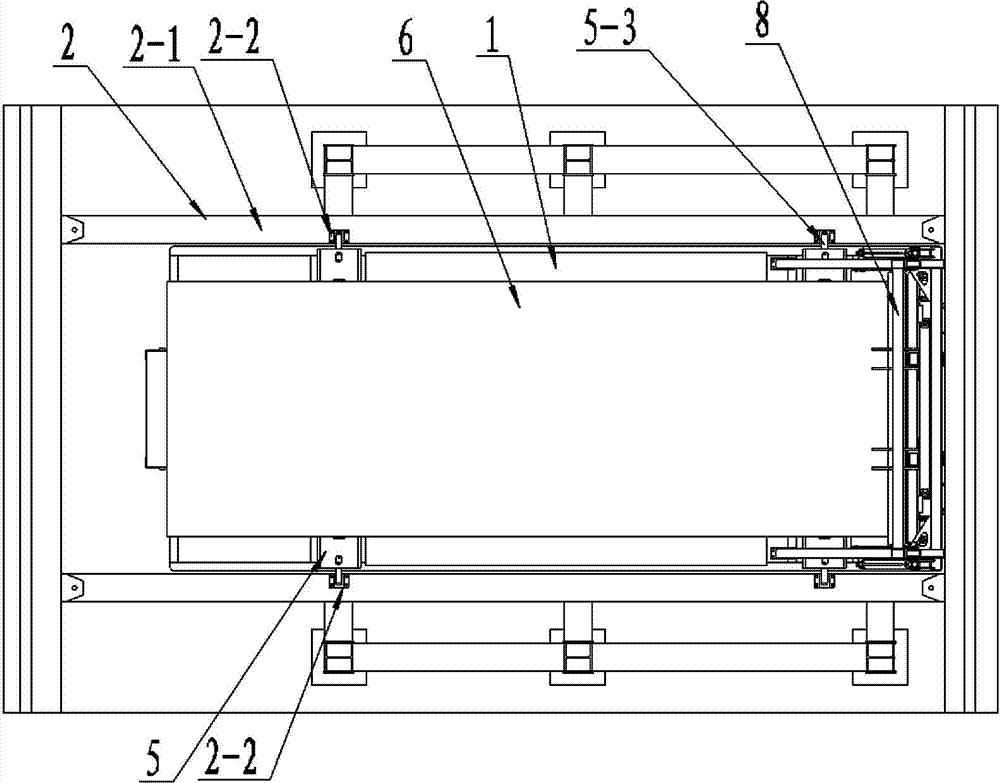

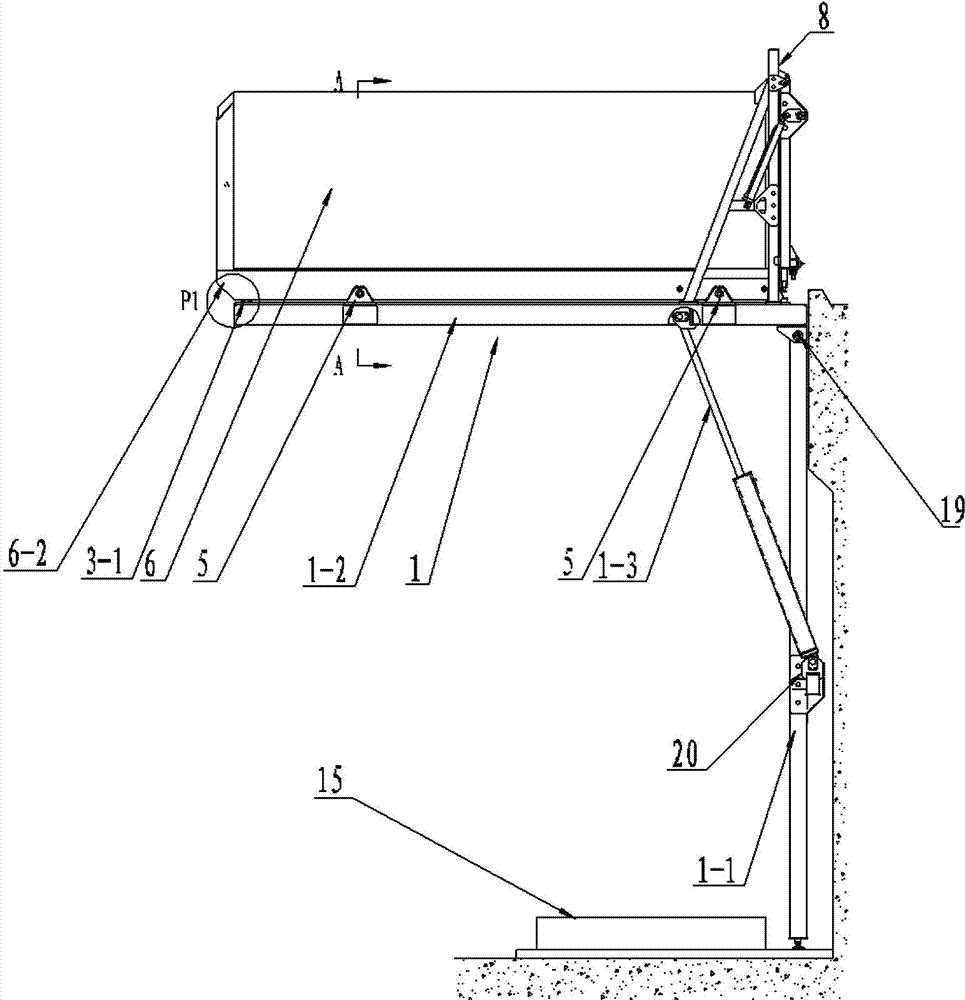

[0051] see Figure 1 to Figure 22 , an automatic container turning and opening and closing device for a vertical garbage compression station, comprising a box turning mechanism 1, a platform positioning frame 2, a latch mechanism 5, a box door turning mechanism 8, a door hanging mechanism 9, and a platform unlocking mechanism 7. The box turning mechanism 1 includes a stand 1-1, a turning platform 1-2, and two first drive cylinders 1-3. The stand 1-1 is installed and fixed in the sinking foundation pit, and the sinking foundation pit The bottom is provided with a supporting platform 15 for supporting the box body after the container is vertically turned over. The turning platform 1-2 adopts a rectangular frame, and the rectangular frame is provided with two platform main beams 1-21 along the longitudinal direction, and a first crossbeam 1 along the horizontal direction. -4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com