Reel centering device for non-woven fabrics

A centering device and non-woven fabric technology, applied in the direction of winding strips, transportation and packaging, and thin material handling, etc., can solve the problems of easy deviation of the reel and poor consistency of non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

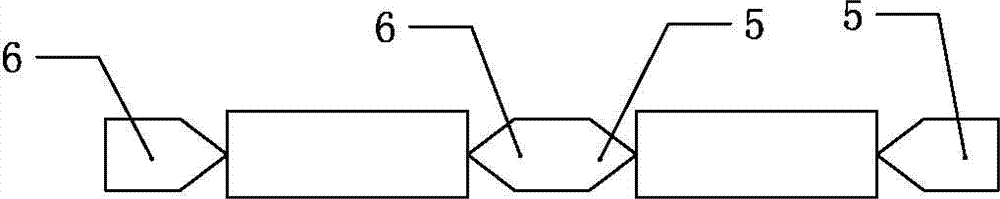

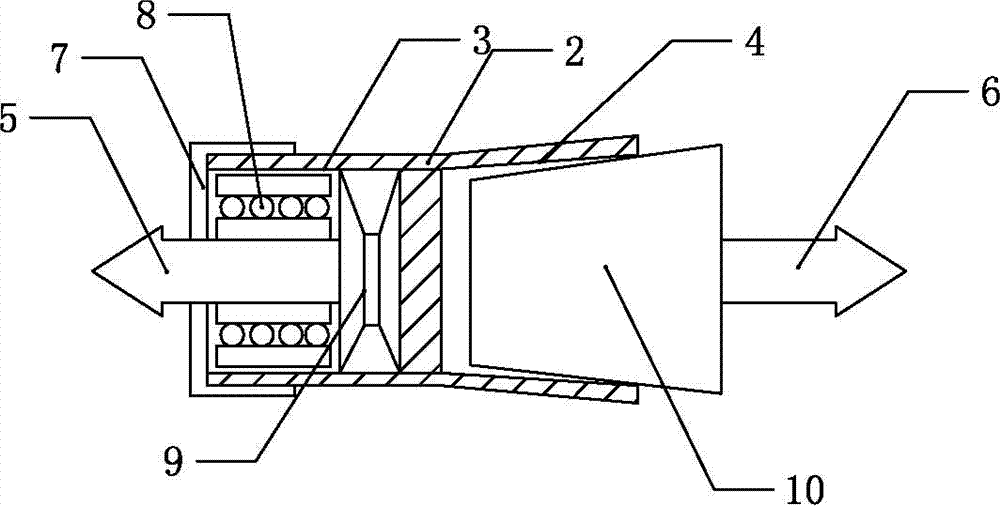

[0016] Such as figure 1 , image 3 As shown, the reel centering device for nonwoven fabrics of the present invention includes two fixed shafts 1 and three centering clips located at both ends of the fixed shafts 1. The fixed shaft 1 is a hollow shaft body, and the centering clips specifically include shells. body 2 and the first top body 5, the shell 2 is a sleeve with an I-shaped longitudinal section, and one side of the I-shape is the first groove 3, and the other side of the I-shape is the second groove 4, and the first groove 3 is provided with a mandrel, the side wall of the mandrel is slidingly connected with the inner wall of the housing 2, a sliding bearing 8 is arranged between the inner wall of the first groove 3 and the outer wall of the mandrel, and the end of the mandrel located in the housing 2 is in contact with the first recess Belleville springs 9 are arranged between the bottoms of the grooves 3, the other end of the mandrel is located outside the housing 2,...

Embodiment 2

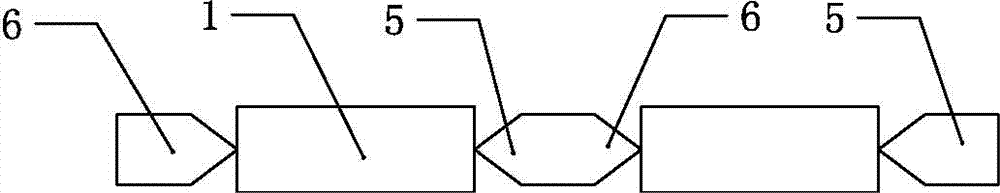

[0019] Such as figure 2 and image 3 As shown, compared with Embodiment 1, in Embodiment 1, "the center of one end of the fixed shaft 1 is against the first tip body 5, and the other end of the fixed shaft 1 is against the second tip body 6" is replaced by: The center of one end of the fixed shaft 1 abuts against the first tip body 5, and the other end of the fixed shaft 1 abuts against the second tip body 6; Both ends of 1 are offset against the second top body 6.

[0020] The first tip body 5 on the left side of the first centering clip is not installed, and the second tip body 6 on the right side is installed, and the first tip body 5 and the second tip body 6 are respectively installed at both ends of the second centering clip. The left side of the third centering clip is equipped with the first tip body 5, and the right side is not equipped with the second tip body 6. The left end of the first fixed shaft 1 is offset against the second tip body 6 of the first centering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com