A support for annealing soft alloy wire

An alloy wire, annealing technology, applied in the direction of furnace, furnace type, heat treatment equipment, etc., can solve the problems affecting the quality of the wire, and achieve the effect of easy manufacturing, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

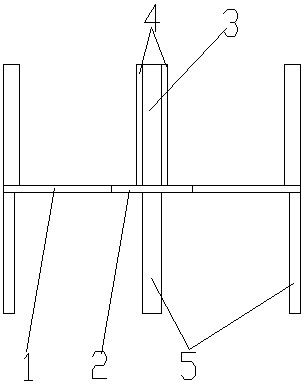

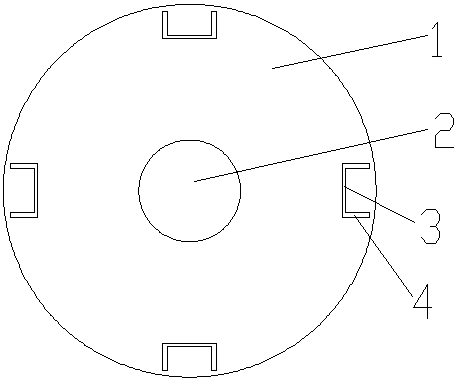

[0018] Such as figure 1 and figure 2 Shown, a kind of support for the annealing of soft state alloy wire rod, it comprises base 1, shaft core 2, frame and inserting plate 5, described base 1 is circular, and its circle center has a circular hole, and inside the circular hole A shaft core 2 matching the diameter of the circular hole is worn, and four frames are vertically fixed at equal intervals on the same side of the circumference of the circular base 1, and the frames include a limiting plate 3 and a supporting plate 4. The limiting plate 3 is an arc vertical plate facing the center of the circular hole, and its two ends are respectively provided with a supporting plate 4 perpendicular to the limiting plate 3 at the center of the circular hole. The plate 4 forms a "ㄩ"-shaped structure; the side of the circular base 1 facing away from the frame is vertically provided with a plug-in board 5 equal to the number of the frame at the corresponding position of the frame, and the...

Embodiment 2

[0023] Same as Example 1, the difference is that three frames are fixed at equal intervals on the same side of the circumference of the circular base 1, which can ensure that the alloy wire becomes soft after the alloy wire reaches a certain annealing temperature and holding time. The lower wires are prevented from being indented by the upper ones, and the quality of the wires is improved, the usage of the frame is minimized, and the cost is reduced.

Embodiment 3

[0025] Similar to Embodiment 1, the difference is that five frames are fixed at equal intervals on the same side of the circumference of the circular base 1, which can improve the overall structural strength of the annealing support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com