F sectional steel connecting structure for medium-low-speed magnetic levitation system

A connection structure and maglev technology, which is applied in roads, tracks, buildings, etc., can solve the problems of insufficient temperature expansion and contraction of rail rows, and achieve the effects of preventing vertical and lateral misalignment, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

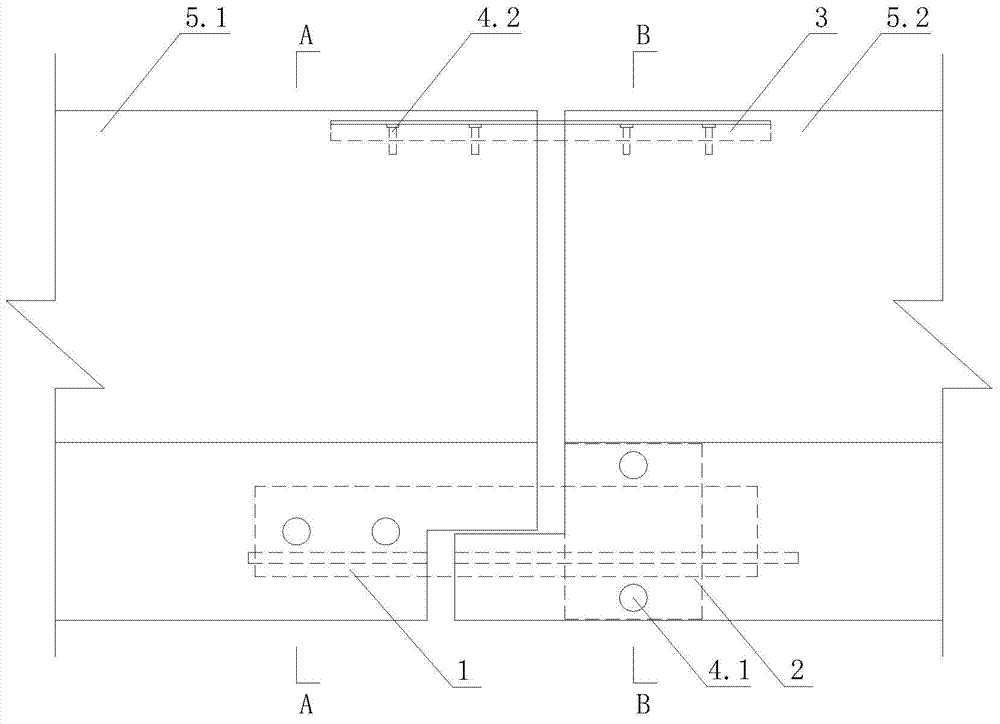

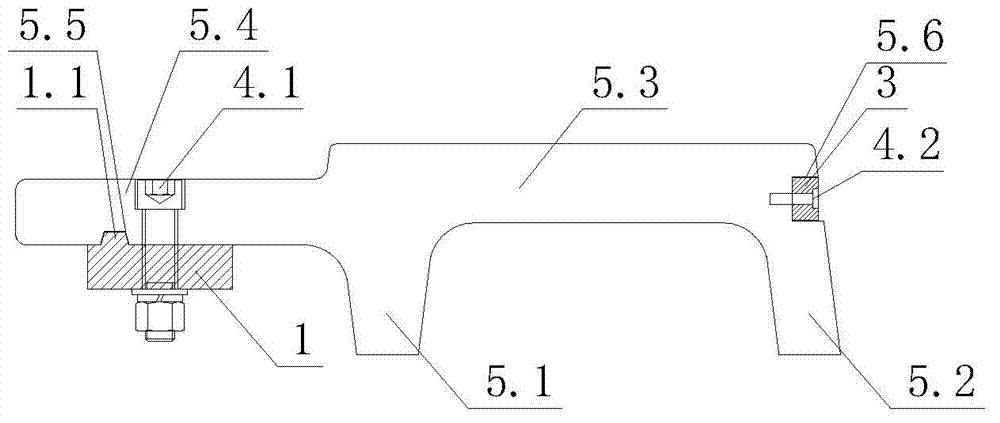

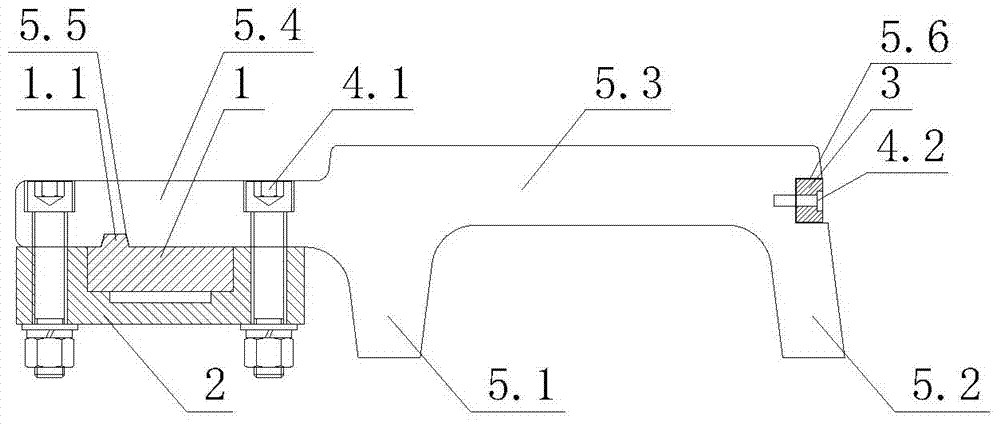

[0018] Embodiment: An F-shaped steel connection structure for a medium-low speed maglev system, including a lower connecting plate 1, a splint 2, an outer leg side connecting plate 3, and two inner legs 5.1, outer legs 5.2, web 5.3 and wing plates 5.4 F-shaped steel 5, the two ends of the lower connecting plate 1 of the wing plate are respectively connected to the wing plates 5.4 on both sides through the first bolt 4.1 and the splint 2, and the side wall of the outer leg 5.2 is provided with a Groove 5.6, the outer leg side connecting plate 3 is provided with a long slot hole 3.1 on the side close to the splint 2, the outer leg side connecting plate 3 is provided with a round hole 3.2 on the side away from the splint 2, the outer leg side connecting plate 3 is provided with a round hole 3.2, the outer The leg side connecting plate 3 is fixed in the groove 5.6 by the second bolt 4.2. The bottom surface of the wing plate 5.4 is provided with a limiting groove 5.5 extending long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com