Novel flow regulating brake valve

A new type of flow regulation technology, applied in the direction of sliding valve, valve device, engine components, etc., can solve the problems of wasting time, not getting flow, and changing the range of flow, etc., to avoid repeated operations, save time, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

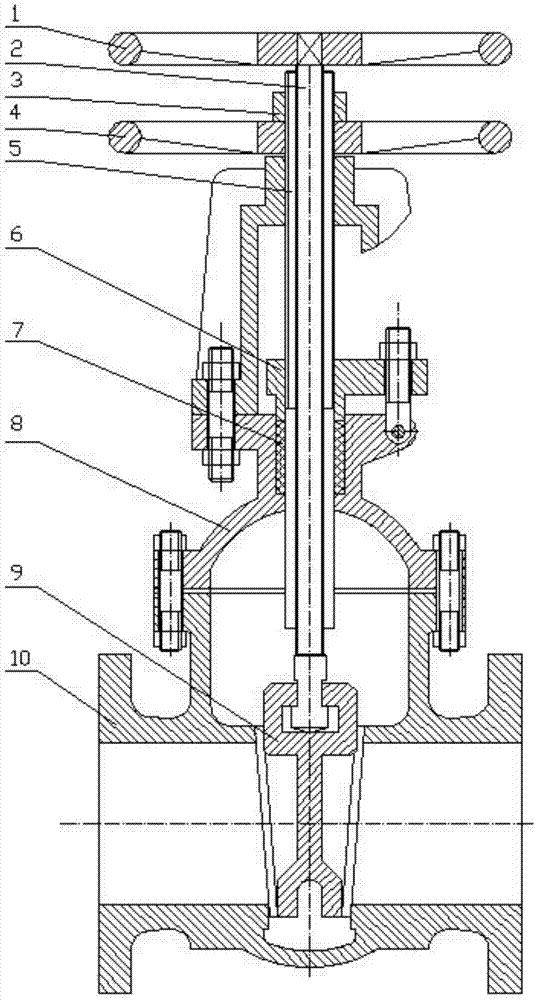

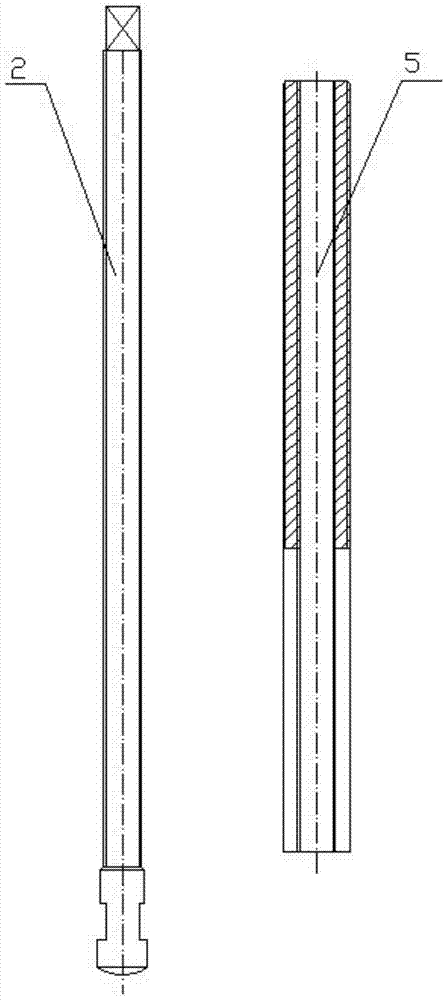

[0013] figure 1 It is a structural schematic diagram of a new type of flow regulating gate valve of the present invention, mainly including a fine-tuning handwheel (1), a fine-tuning valve stem (2), a stem nut (3), a coarse-tuning handwheel (4), and a coarse-tuning valve stem ( 5), packing pressure plate (6), packing (7), valve cover (8), gate (9), valve body (10) and other structures.

[0014] Coarsely adjust the flow rate or when the flow rate is required to be fully open or fully closed, turn the coarse adjustment handwheel (4) to move the coarse adjustment valve stem (5) up and down, which can realize rapid flow changes and save time; when the flow rate is finely adjusted, turn the fine adjustment handwheel (1), hold the coarse adjustment handwheel (4) at the same time, and make the fine adjustment valve stem (2) move up and down slightly, so as to realize the fine adjustment of the flow rate and save time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com