Integrated active muffler integrated with high pressure liquid filling pipeline

A liquid-filled pipeline and muffler technology, which is applied to pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems that the muffler cannot track the noise frequency and cannot adapt to the change of the noise frequency of the pipeline system The sound effect is good, the effect of the noise reduction frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

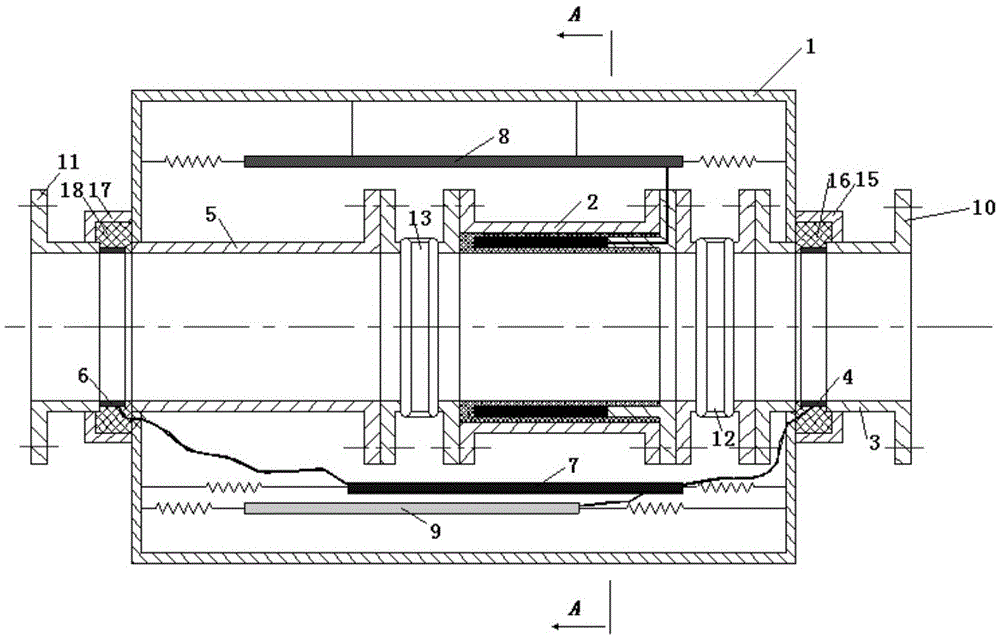

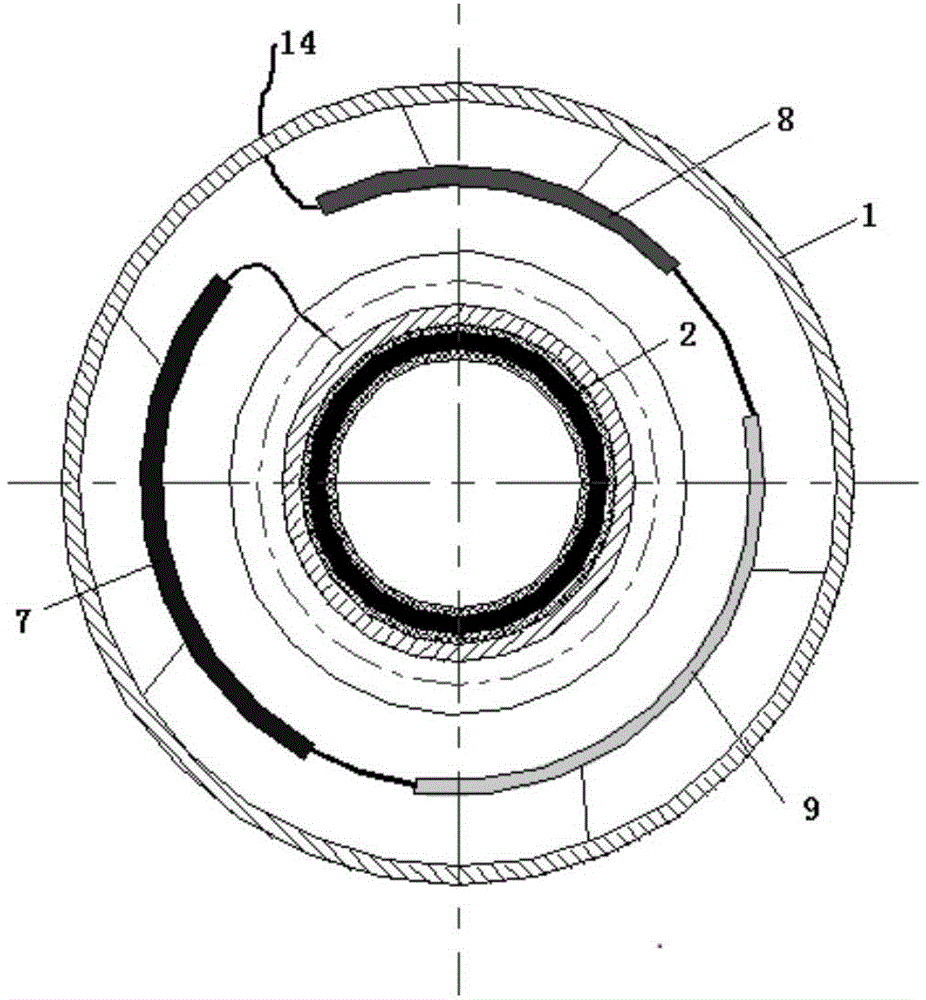

[0016] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

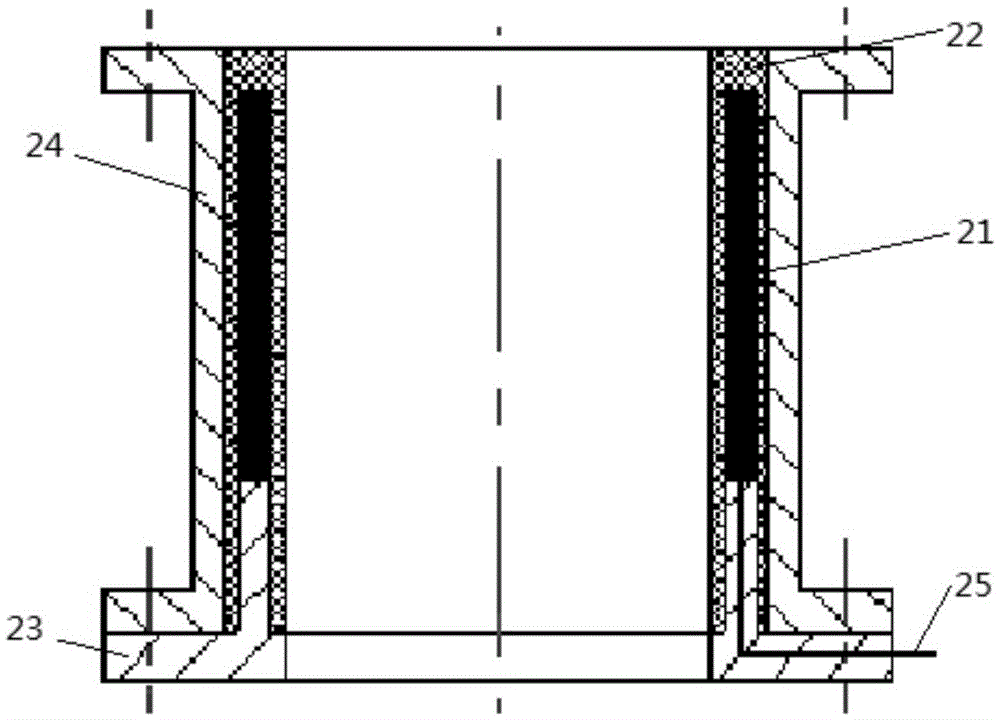

[0017] combine Figure 1-Figure 3 , the high-pressure liquid-filled pipeline integrated active muffler based on tubular piezoelectric ceramic actuators of the present invention includes a shell 1, a tubular piezoelectric ceramic actuator 2 arranged in the middle of the shell, an upstream pipe section 3 and its Inner upstream pipeline pressure pulsation sensor 4, downstream pipeline section 5 and downstream pipeline pressure pulsation sensor 6 installed inside it, signal pickup and conditioning system 7, power amplification system 8, DSP-based high-speed signal processing system 9, upstream and downstream connection method Blue 10,11, elastic connection 12,13.

[0018] The present invention is installed in the pipeline system through two flanges 10, 11; the tubular piezoelectric ceramic actuator 2 is connected with the upstream pipe section 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com