Low-noise pneumatic tire tread pattern

A technology for pneumatic tires and tread patterns, applied to tire treads/tread patterns, tire parts, vehicle parts, etc., can solve the problems of small number of resonators, large size, and no consideration of secondary split peaks of resonators , to achieve the effect of widening the anechoic frequency band, strengthening the attenuation effect, and small feature size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

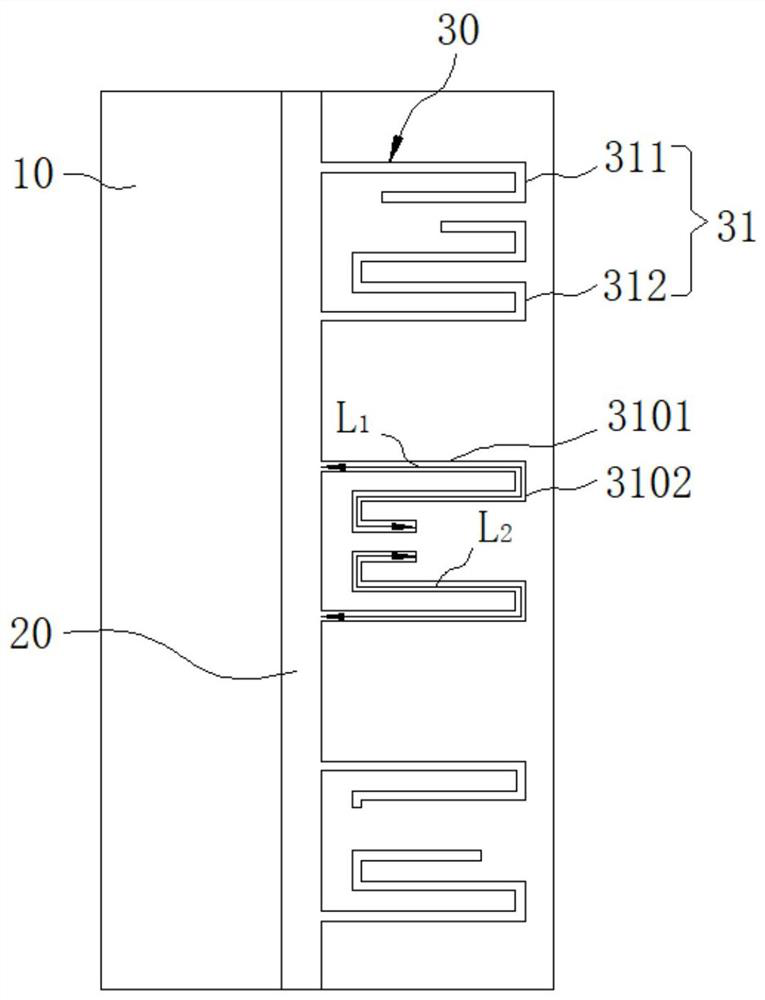

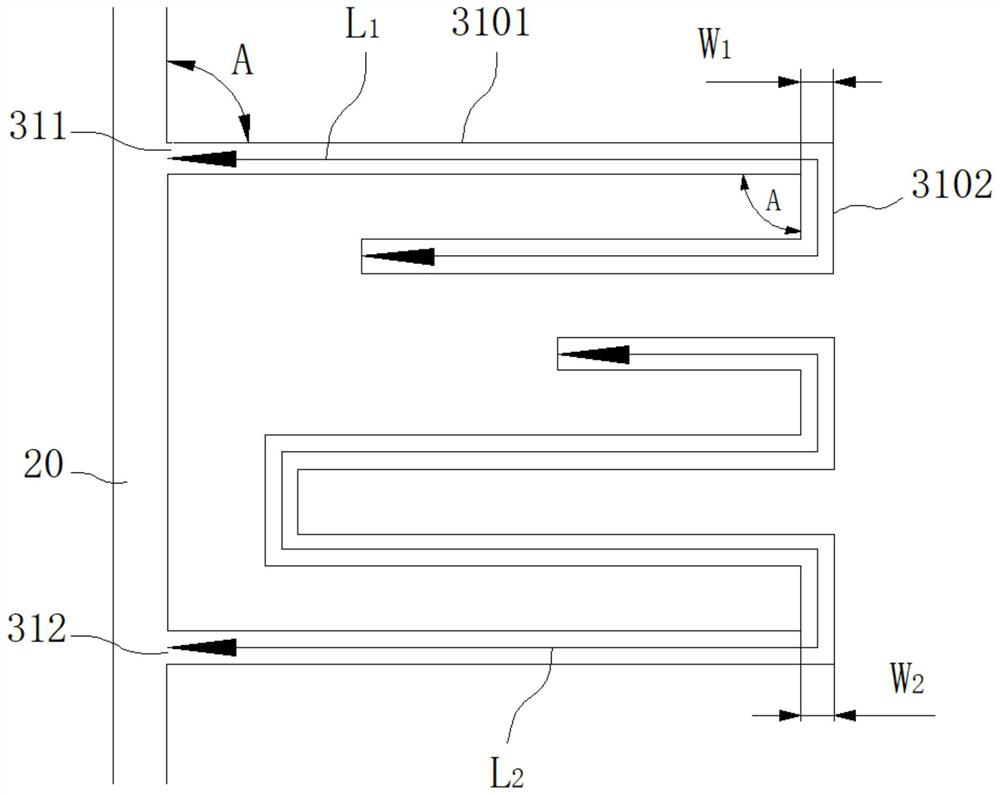

[0032] refer to figure 1 , figure 2 , Figure 6 , Figure 7 , a tread pattern of a low-noise pneumatic tire, comprising a longitudinal groove 20 extending circumferentially along a crown 10 and a plurality of resonators 30 spaced apart from each other and connected in parallel on one side of the longitudinal groove 20, each resonator comprising:

[0033] Two adjacent narrow grooves 31, each narrow groove extends along the crown surface away from the longitudinal groove to form a plurality of end-to-end transverse passages 3101 and vertical passages 3102, and the angle between the first extending transverse passage away from the direction of the longitudinal groove is A, in this embodiment A is 90°, and the vertical channels are distributed parallel to the longitudinal grooves, and the adjacent horizontal channels are arranged in parallel;

[0034] Wherein, the number of end-to-end contact points between the transverse channel 3101 and the vertical channel 3102 is at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com