Double-cavity coupling Helmholtz silencer and control method

A muffler and control system technology, which is applied in the direction of sound-emitting devices and instruments, can solve the problem that the noise reduction effect of the resonator is not greatly improved, and achieve the effects of increased transmission loss, improved flame stability, and improved noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

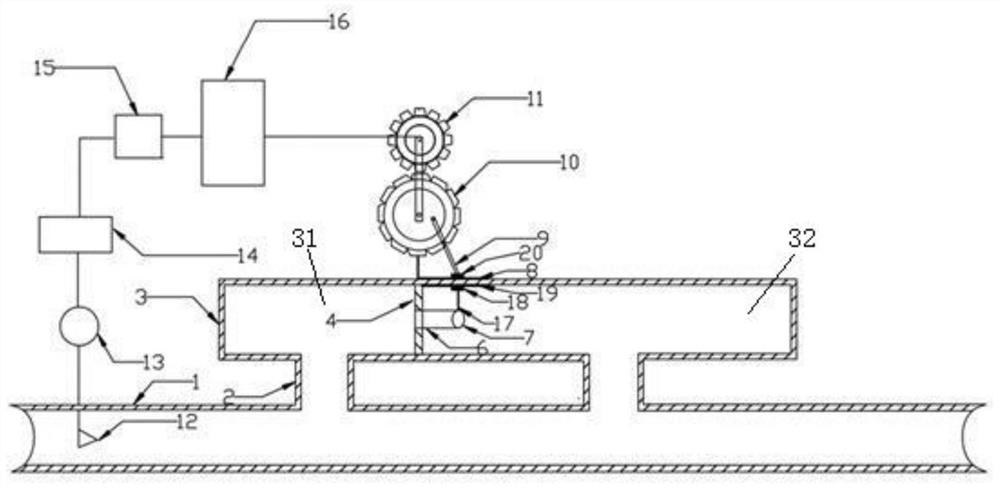

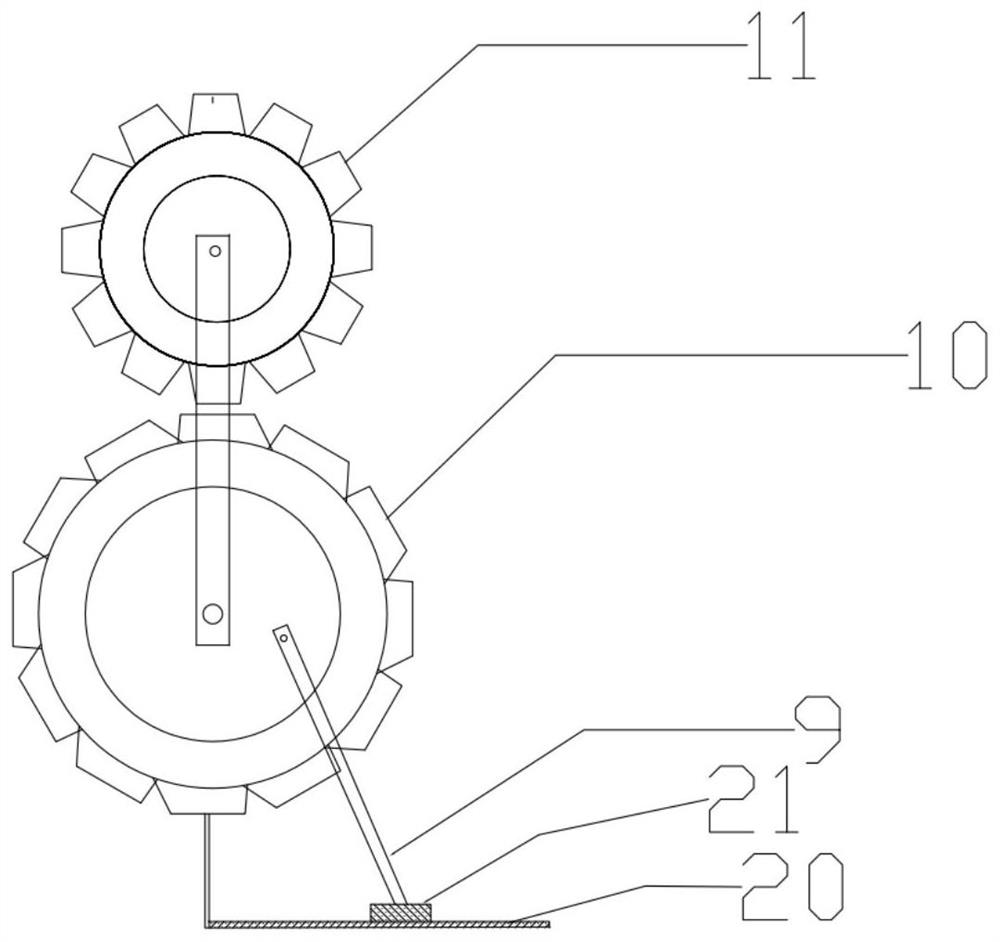

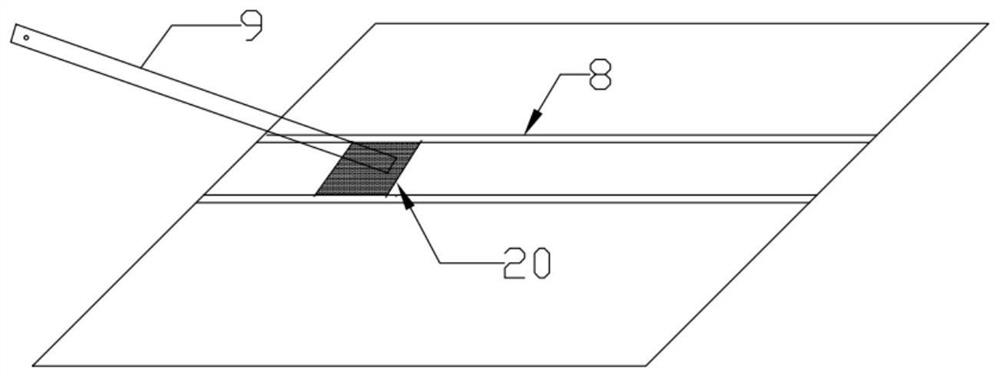

[0030] Such as Figure 1-5 As shown, the present invention provides a dual-cavity coupling Helmholtz muffler and a control method, including a main pipe 1, a short neck pipe 2, a resonance chamber 3, a control system, a gear transmission system, and a telescopic extension pipe assembly; the resonance chamber 3 is provided with a baffle plate 4, and the resonant cavity 3 is divided into a first cavity 31 and a second cavity 32, and the neck short tube 2 is provided with two, respectively connecting the first cavity 31 and the second cavity 32 with the main cavity The pipeline 1 is connected, and the seal between the three is good. The telescopic extension tube assembly is arranged in the second cavity 32. The first cavity 31 and the second cavity 32 are two cylinders placed horizontally. The second cavity 32 The volume is greater than the volume of the first cavity 31; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com