Automatic sealing exhaust equipment for solar vacuum pipe

A technology of automatic sealing and exhaust equipment, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of high labor intensity and low efficiency, and achieve reduced labor intensity, simple equipment structure, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

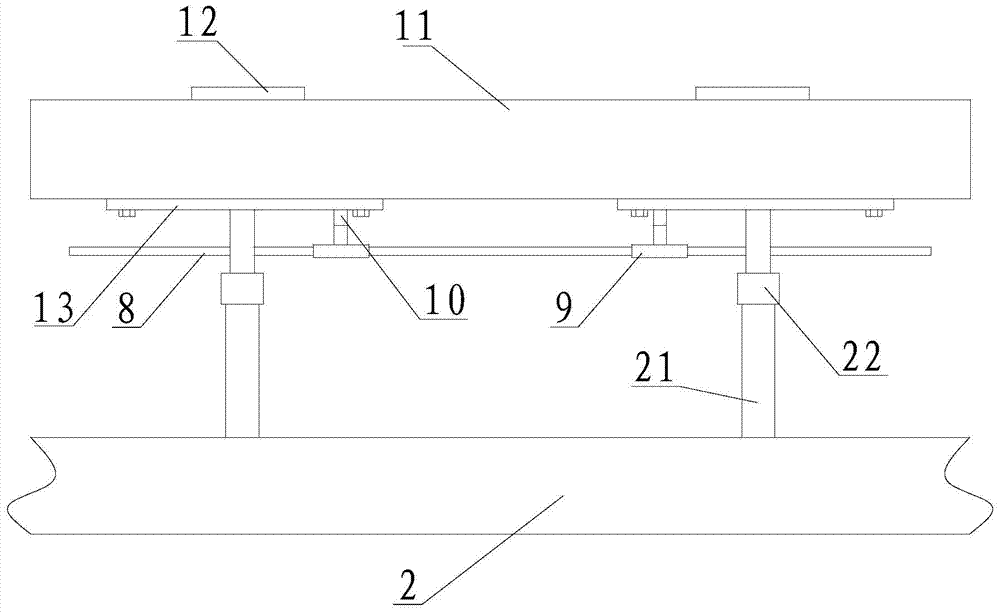

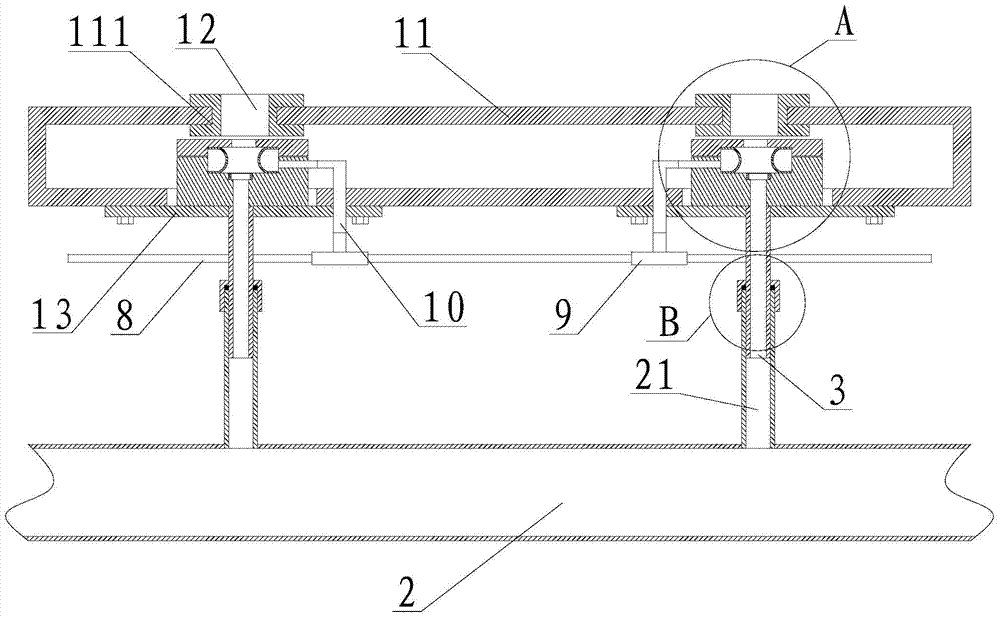

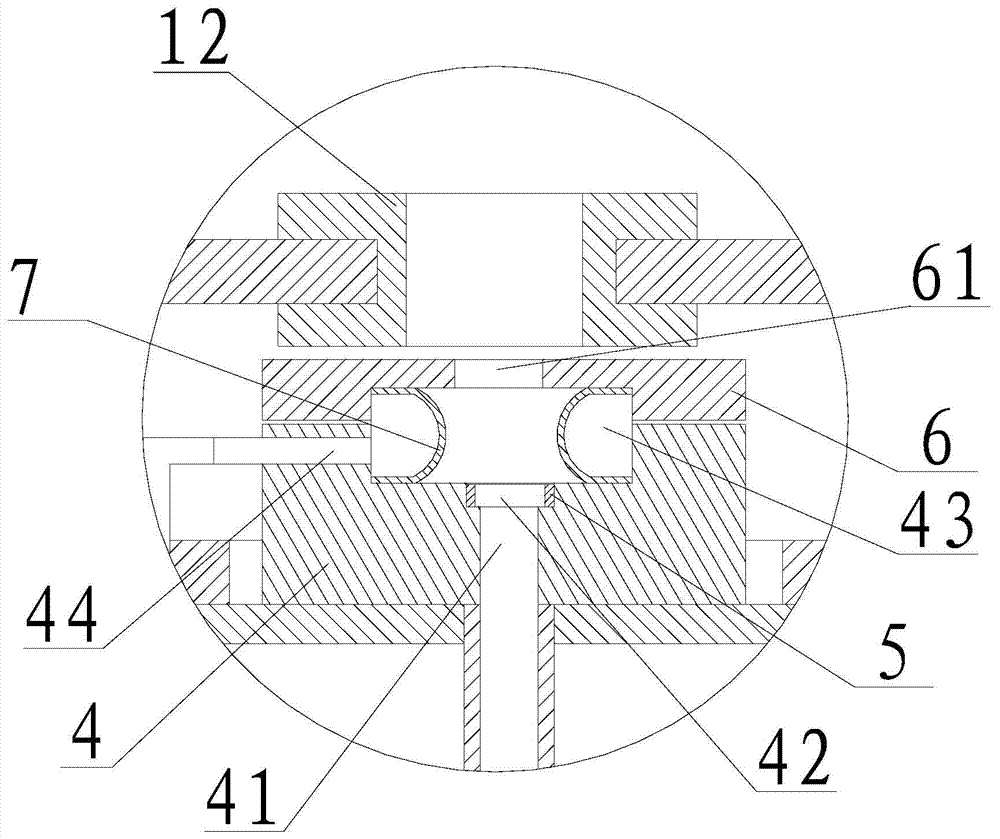

[0020] refer to figure 1 , figure 2 , image 3 and Figure 4 , a solar vacuum tube automatic sealing and exhausting device of the present invention, comprising a main vacuum pipeline 2, a joint connecting pipe 3, a joint seat 4, a buffer ring 5, a joint cover 6, an air pressure shrinkage ring 7, an air pressure main pipe 8, a tee 9, an air pressure In charge of 10, workbench 11, protection ring 12 and lower cover 13, the upper part of the workbench 11 is provided with a material insertion port 111, and the protection ring 12 is installed on the described material insertion port 111, and the lower part of the workbench 11 passes through 2 The lower cover plate 13 is fixedly installed by ~6 bolts, the joint seat 4 is installed on the cover plate, and the joint seat 4 is provided with a negative pressure channel 41, a buffer groove 42, a clamping chamber 43 and an air injection channel 44, A joint connection pipe 3 is installed on the negative pressure channel 41, a buffer ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com