A power device junction terminal structure

A technology of power devices and junction terminals, which is applied in the field of power semiconductors, can solve problems such as limited withstand voltage capability, complex overall structure and applicable conditions, and multi-device area, so as to reduce the drop of withstand voltage and improve the ability to resist total dose radiation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the drawings

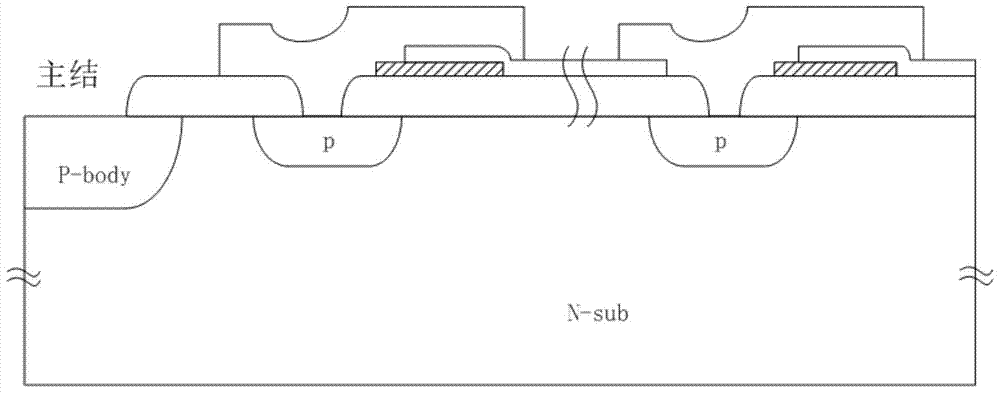

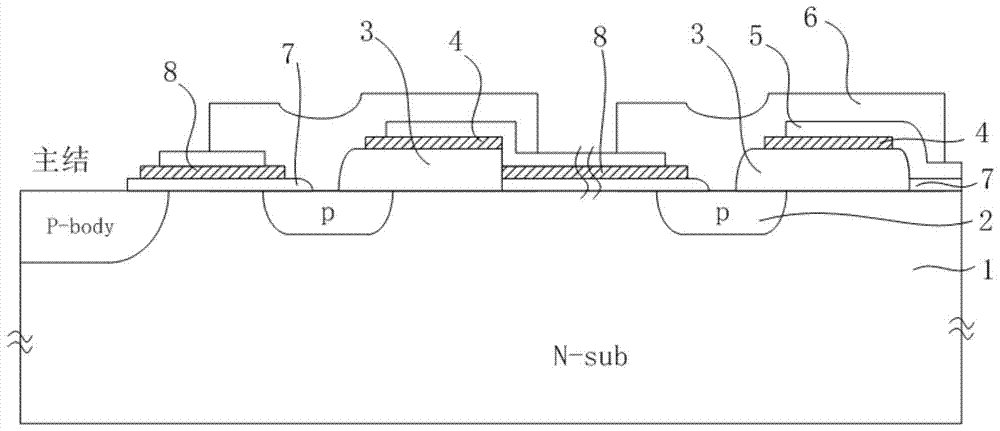

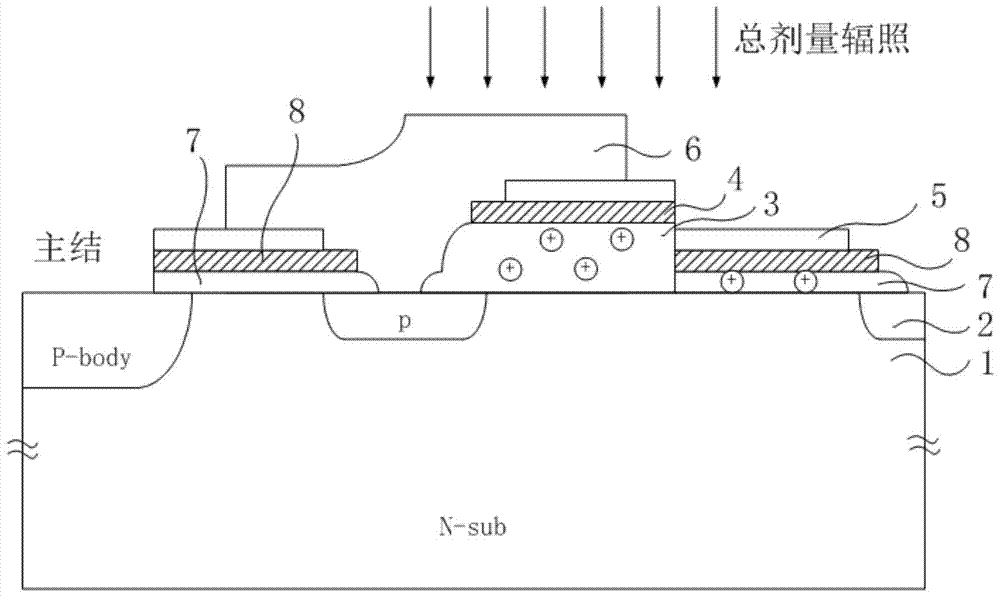

[0018] Such as figure 2 As shown, the power device junction termination structure of the present invention includes a substrate 1 and a plurality of field limiting rings 2 spaced apart on the upper layer of the substrate 1; the upper surface of the field limiting ring 2 is connected to the first field on the side close to the main junction The oxide layer 7 is connected to the second field oxide layer 3 on the other side of its upper surface; the thickness of the second field oxide layer 3 is greater than the thickness of the first field oxide layer 7; the upper surface of the first field oxide layer 7 has a A polysilicon field plate 8; the upper surface of the second field oxide layer 3 has a second polysilicon field plate 4; the first polysilicon field plate 8 and the second polysilicon field plate 4 have upper surfaces The dielectric layer 5; the upper surface of the dielectric l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com