Mechanism for laying down seat back and unlocking seat sliding rail

A seat back and seat technology, which is applied to movable seats and other directions, can solve the problems of scattered structure, low integration, and reduce the assembly efficiency of the whole chair, and achieve the effect of reducing assembly difficulty and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

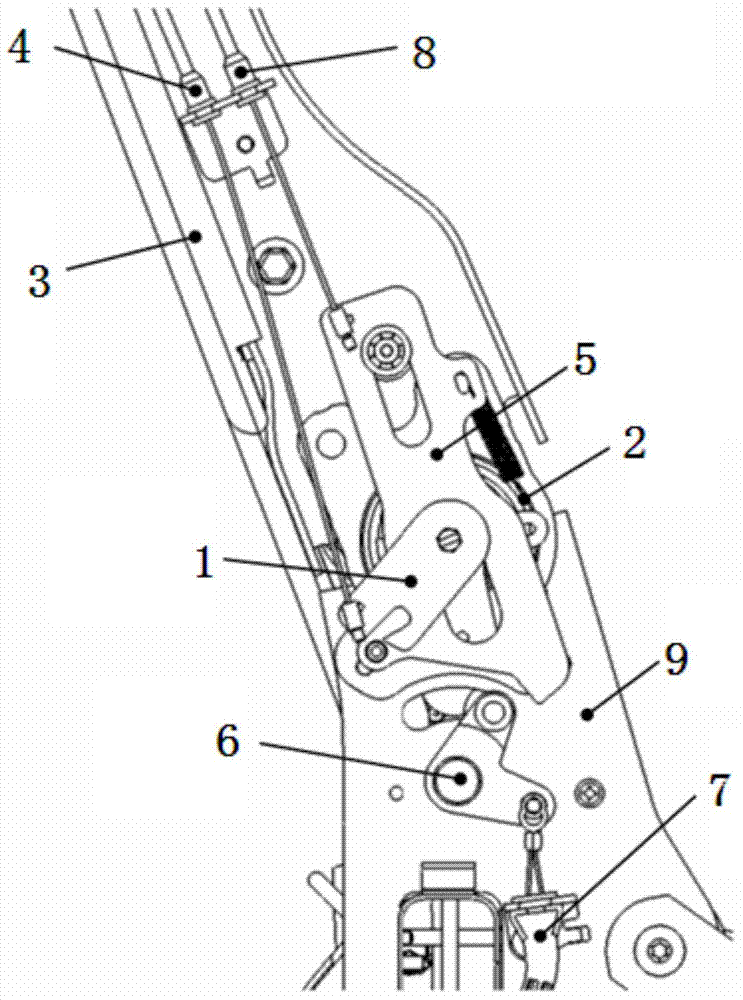

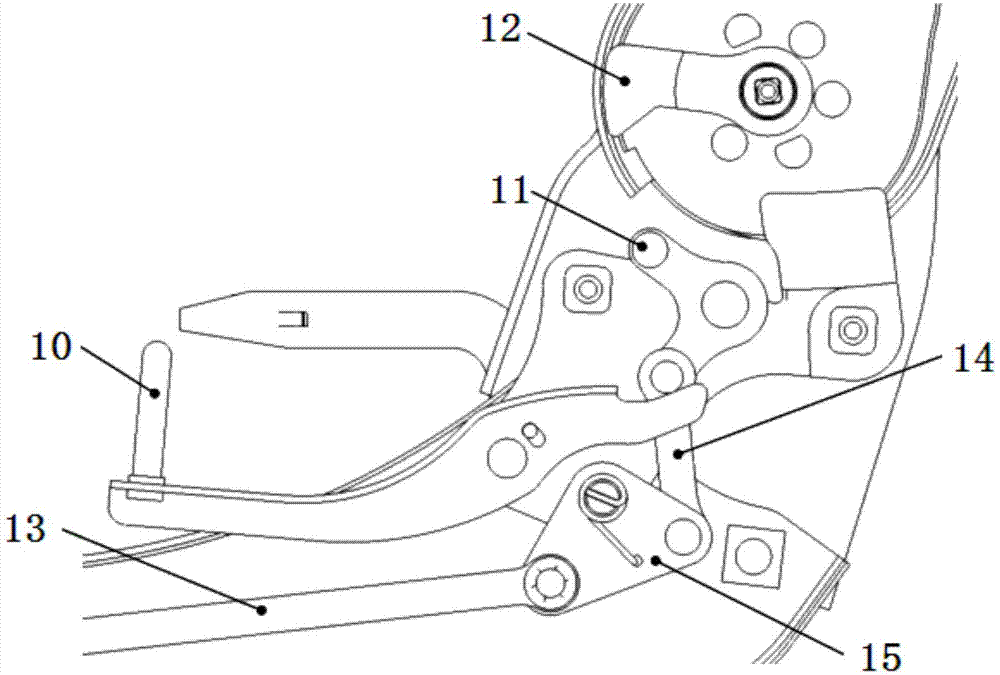

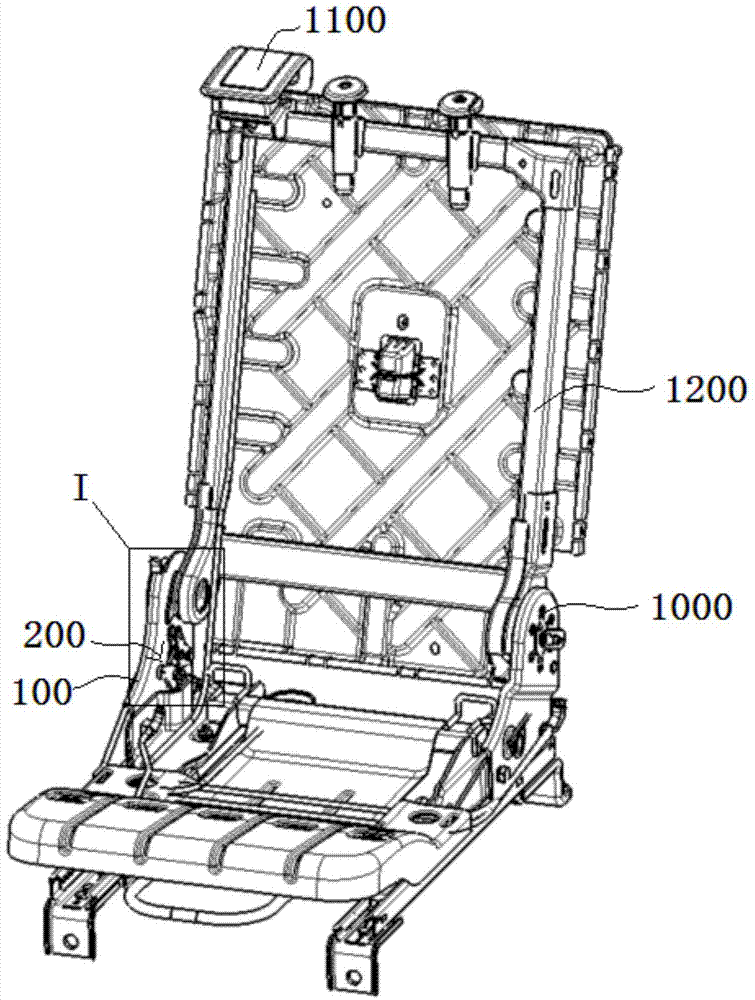

[0065] see image 3 with Figure 4 , a mechanism 200 for laying down the seat back and simultaneously unlocking the seat slide rail is provided in the figure, which is installed on the lower connecting plate 100 of the backrest on one side of the seat. The operating handle 1100 of the mechanism 200 for controlling the reclining of the seat back and unlocking the seat slide rail at the same time is installed on the seat back 1200 , which is convenient for rear passengers to operate. The operating handle 1100 is connected with the recliner unlocking cable.

[0066] see in conjunction Figure 5 to Figure 8 as well as Figure 23 , Figure 24 , the mechanism 200 for laying down the seat back and unlocking the seat slide rail at the same time includes two lower trigger sheet metal parts 210, 220 with the same structure, and the two lower trigger sheet metal parts 210, 220 are configured with A pair of coaxial first holes 211, 221, a pair of coaxial second holes 212, 222, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com