Oil cooler

An oil cooler and cooling oil technology, applied in heat exchanger shells, lighting and heating equipment, heat exchange equipment, etc., can solve problems such as low cooling efficiency, improve cooling efficiency, smooth oil paths, and ensure oil cooling area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

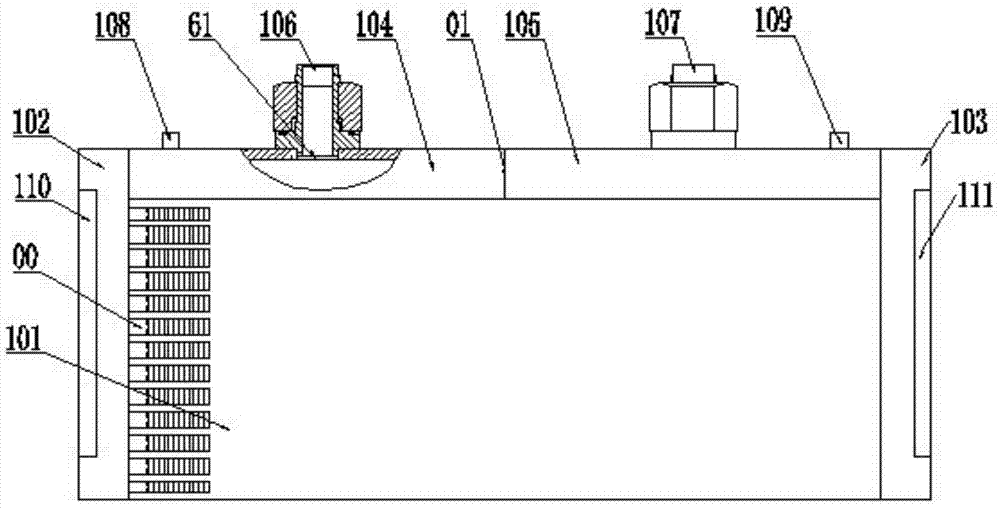

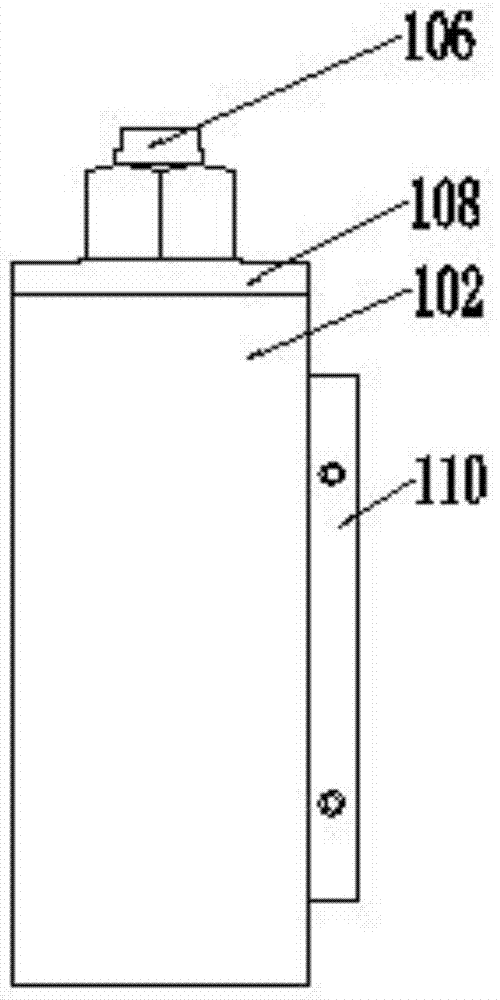

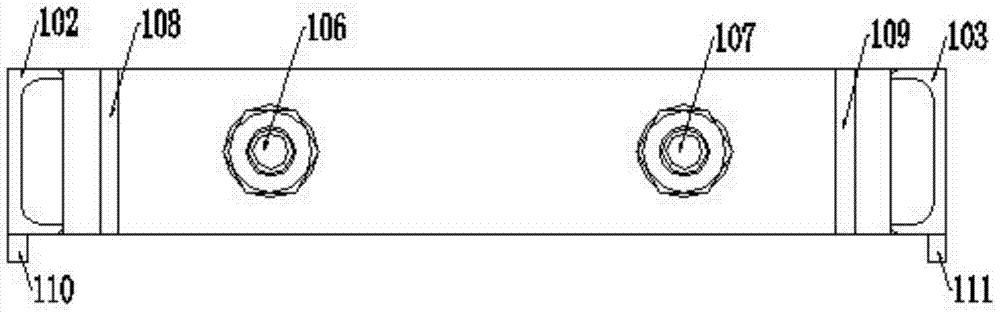

[0028] figure 1 It is the front view of the oil cooler provided by Embodiment 1 of the present invention; figure 2 It is the left side view of the oil cooler provided by Embodiment 1 of the present invention; image 3 It is a top view of the oil cooler provided by Embodiment 1 of the present invention; Figure 4 It is a cross-sectional view of the oil inlet pipe in the oil cooler provided by Embodiment 1 of the present invention; as shown in the figure, the oil cooler provided by Embodiment 1 of the present invention includes: a cooling body 101 with a cooling core 00 for cooling oil built in, cooling The top of the body 101 is packaged with an upper head, the left and right sides of the cooling body 101 are respectively packaged with a left head 102 and a right head 103, and the upper head is separated into a left upper head 104 and a right upper head 105 by an inner sealing plate 01, The upper left head 104 is provided with an oil inlet pipe 106, and the upper right head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com