Balancing or measuring device

A measuring device and balancing technology, applied in the direction of manufacturing tools, mechanical equipment, chucks, etc., can solve the problems of manufacturing the rotor with the precision of the receiving hole of the base body, sensitive to wear of the centering parts, and crushing of the coupling rod, etc., to achieve high elasticity , Stable rotation centering, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

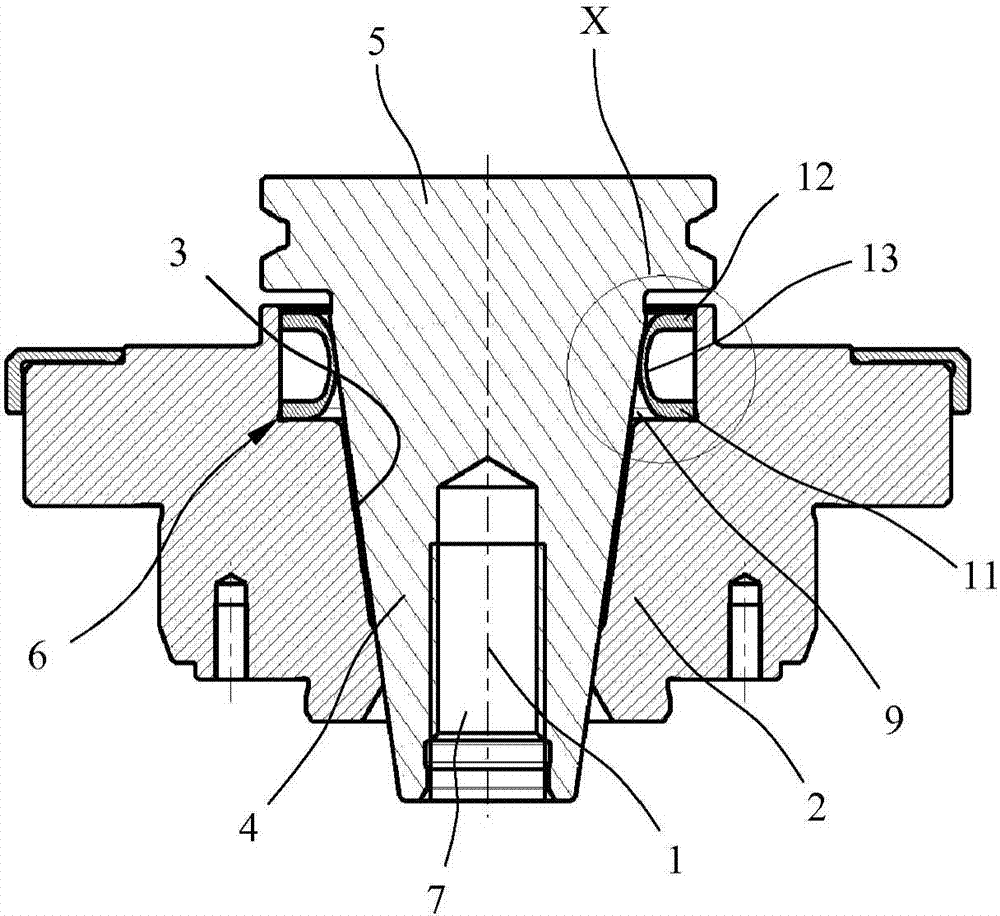

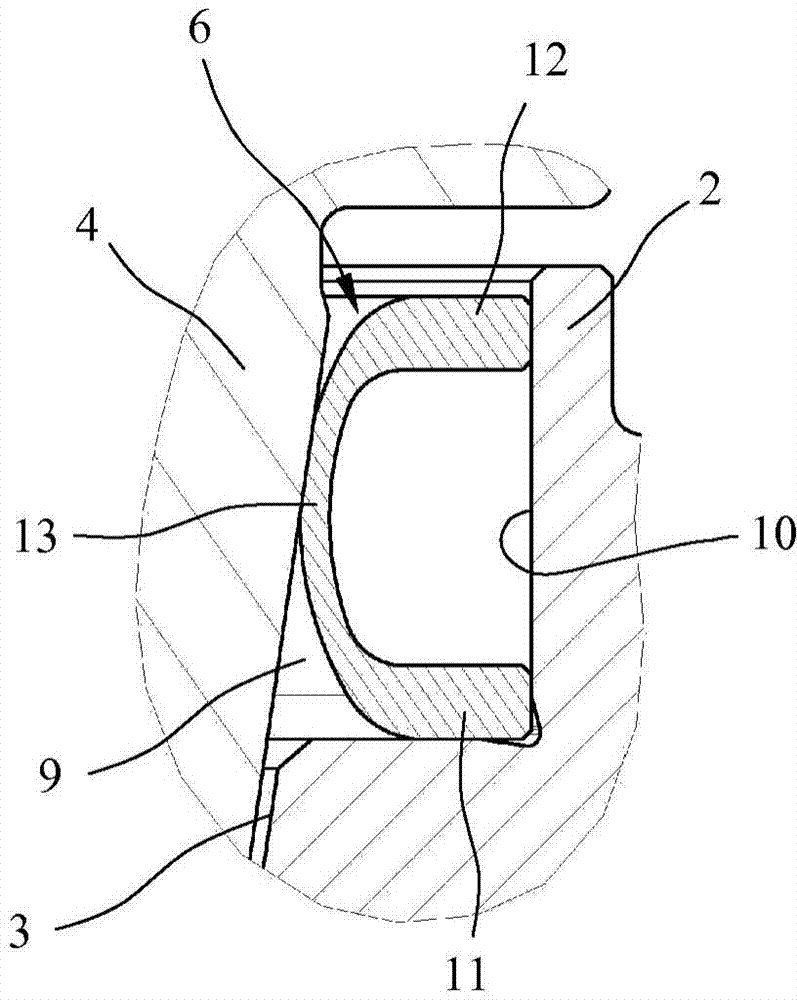

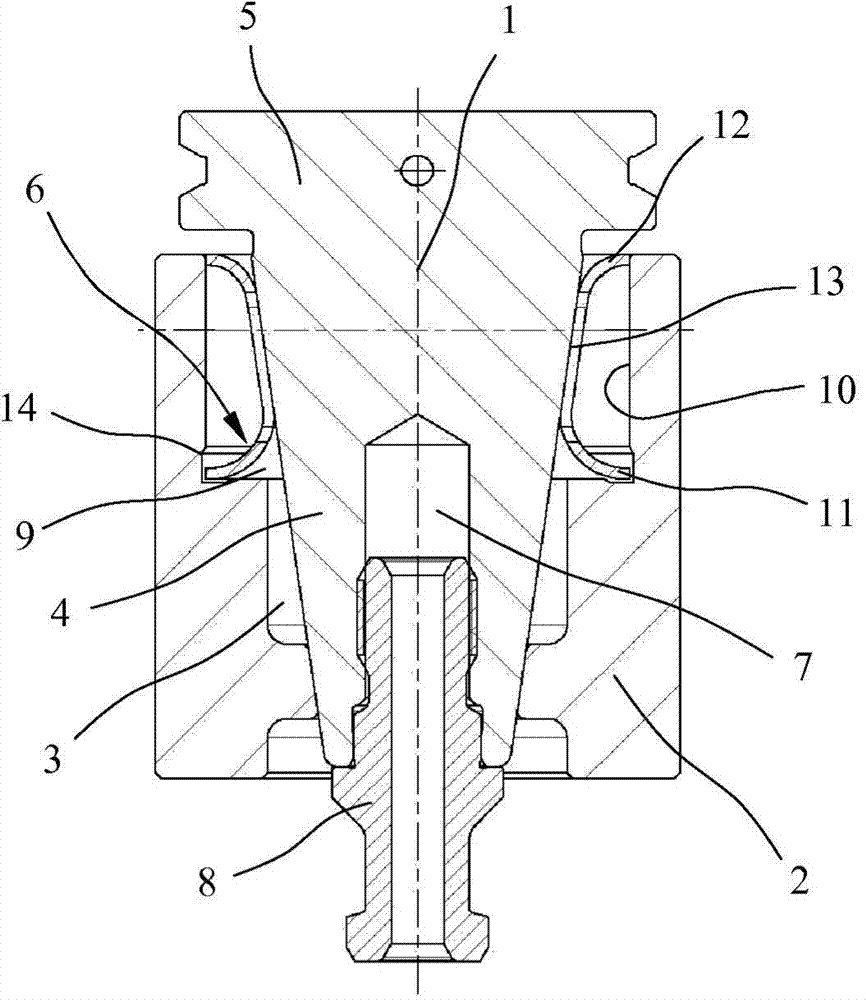

[0037] figure 1 Shown is a base body 2 rotating about an axis of rotation 1 , which includes a conical receiving hole 3 for receiving a coupling rod 4 of a rotor 5 . The rotor 5 can be, for example, a tool holder, a tool or another component to be balanced or measured. Arranged in the base body 2 is an annular centering element 6 for pivotally centering the tool holder 5 within the receiving opening 3 of the base body 2 . The base body 2 and the centering part 6 are components of a balancing or measuring device which are installed in a balancing or measuring machine for balancing or measuring rotating components. In the exemplary embodiment shown, the base body 2 is designed as an adapter for fastening to a machine spindle. As a result, the balancing or measuring device can be adapted relatively quickly and easily to different types of coupling rods on the tool or tool holder. However, base body 2 can also be the motor-driven machine spindle itself.

[0038] The rotor 5 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com