A method for hot-melt lamination of clothing edges seamlessly without slits

A technology of seamless edge and hot-melt paste, which is applied to corsets, sewing tools, clothing, etc., can solve the problems of high production cost, waste of materials, irreparable problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

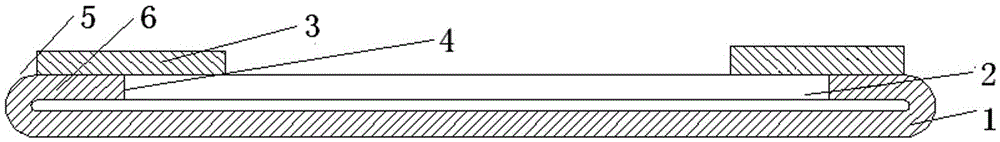

Image

Examples

Embodiment 1

[0022] A method for seamlessly slit-free hot-melt bonding of clothing edges, characterized in that it comprises the following steps:

[0023] Step 1: Select two elastic fabrics as the lining and fabric of the clothing;

[0024] Step 2: Use the cutting machine to cut the lining and fabric by 0.8cm around the actual size, and the surrounding of the fabric is 1.4cm wider than the lining;

[0025] Step 3: Make a mold according to the shape of the hot-melt joint of the clothes and the size of the flanging. The flanging size is 4MM. The knife edge of the mold is upward, and the front edge is less than 0.1MM. The trajectory of the knife edge is consistent with the shape of the hot-melt bonding place of the clothes ;

[0026] Step 4: Place the fabric, pressing plate, lining and paper on the mold in turn. The thickness of the pressing plate is 8MM, and its outer contour just coincides with the trajectory of the mold knife edge. Put a panel with pits on the paper. The panel is divided ...

Embodiment 2

[0030] A method for seamlessly slit-free hot-melt bonding of bra flank edges, characterized in that it comprises the following steps:

[0031] Step 1: Choose two elastic fabrics for the lining and fabric of the bra flanks;

[0032] Step 2: Use the cutting machine to cut the lining and fabric by 0.8cm around the actual size, and the surrounding of the fabric is 1.4cm wider than the lining;

[0033] Step 3: Make a mold according to the shape of the hot-melt joint of the bra flank and the size of the flanging. The flanging size is 4MM, the knife edge of the mold is upward, and the front edge is less than 0.1MM. The track of the knife edge and the bra flank need to be hot-melt bonded. Consistent shape;

[0034] Step 4: Place the fabric, pressing plate, lining and paper on the mold in turn. The thickness of the pressing plate is 8MM, and its outer contour just coincides with the trajectory of the mold knife edge. Put a panel with pits on the paper. The panel is divided into The s...

Embodiment 3

[0038] A method for seamlessly slit-free hot-melt bonding of clothing edges, characterized in that it comprises the following steps:

[0039] Step 1: Select two elastic fabrics as the lining and fabric of the clothing;

[0040] Step 2: Use the cutting machine to cut the lining and fabric by 1.0cm around the actual size, and the fabric is 1.5cm wider than the lining;

[0041] Step 3: Make a mold according to the shape of the hot-melt joint of the clothes and the size of the flanging. The flanging size is 5MM. The knife edge of the mold is upward, and the front edge is less than 0.1MM. The trajectory of the knife edge is consistent with the shape of the clothes that need to be hot-melted ;

[0042] Step 4: Place the fabric, press plate, lining and paper on the mold in turn. The thickness of the press plate is 10MM, and its outer contour just coincides with the trajectory of the mold knife edge. Put a panel with pits on the paper. The panel is divided into The second layer, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com