Magnetic induction switch and manufacturing method thereof

The technology of a magnetic induction switch and a manufacturing method, which is applied in the electronic field, can solve problems such as poor solder joints, poor reliability of magnetic induction switches, and difficult operation, and achieve the effects of long service life, stable fixation, and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment proposes a magnetic induction switch with convenient manufacture and high reliability and a manufacturing method thereof.

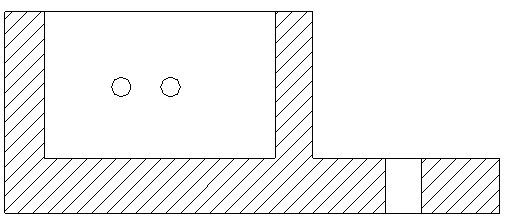

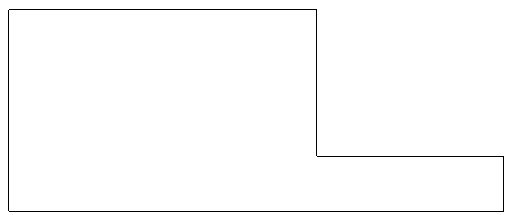

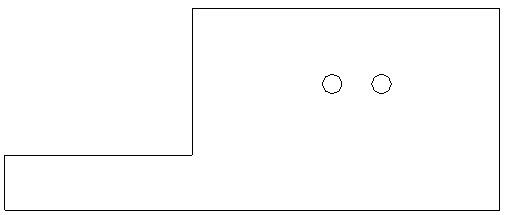

[0025] Such as Figure 4-8 As shown, the magnetic induction switch of this embodiment includes a sensor 1 and a housing 2 formed by injection molding. The housing 2 is a cuboid. One side of the housing 2 is provided with a protruding support plate 3, and the support plate 3 is provided with a magnetic induction switch for fixing. The housing 2 is provided with a sensor accommodating cavity 5, one end of the sensor accommodating cavity 5 is open, and the side of the other end is provided with a glue injection port 6 communicating with the outside; the sensor 1 is located in the sensor accommodating cavity 5 , the wire 13 of the sensor 1 is led out from the open end of the sensor accommodating cavity 5 , and the sensor accommodating cavity 5 is filled with glue 12 . The above-mentioned glue can be hot-melt glue or the like, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com