Dielectric barrier fuel charge device

A charging device and medium barrier technology, applied in the charging system, combustion engine, internal combustion piston engine, etc., can solve the problems of weak connection, leakage, oil pipeline falling off, etc., to achieve good atomization and distribution uniformity, The effect of reducing pollution emissions and increasing flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

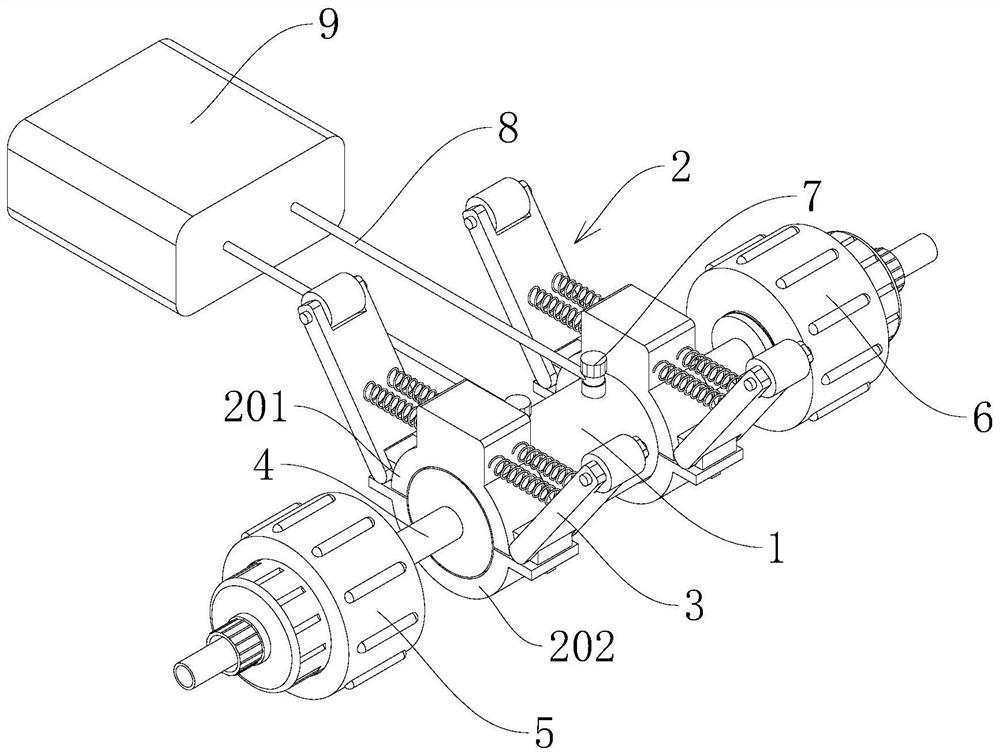

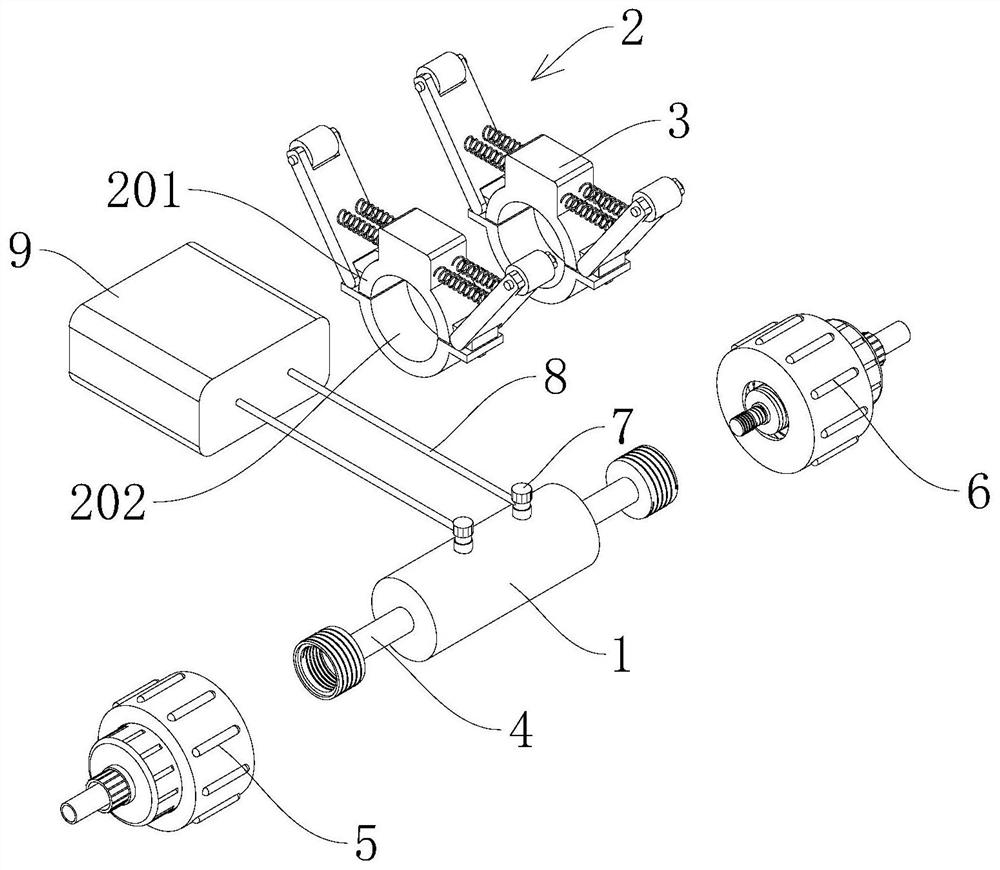

[0032] see Figure 1-3 , a dielectric barrier fuel charging device, including a fuel charging mechanism 1, the fuel charging mechanism 1 is connected with a shock absorbing device 2, the mounting shock absorbing device 2 includes a connecting mechanism, and the connecting mechanism includes an upper connecting half ring 201 and the lower connecting half-ring 202, the upper connecting half-ring 201 is connected with the shock absorbing mechanism 3, the lower connecting half-ring 202 is fixedly installed on the upper connecting half-ring 201 by fixing bolts; the two ends of the fuel charging mechanism 1 are connected with communicating pipes 4. The end of the connecting pipe 4 away from the fuel charging mechanism 1 is respectively connected with a first fuel filter device 5 and a second fuel filter device 6 .

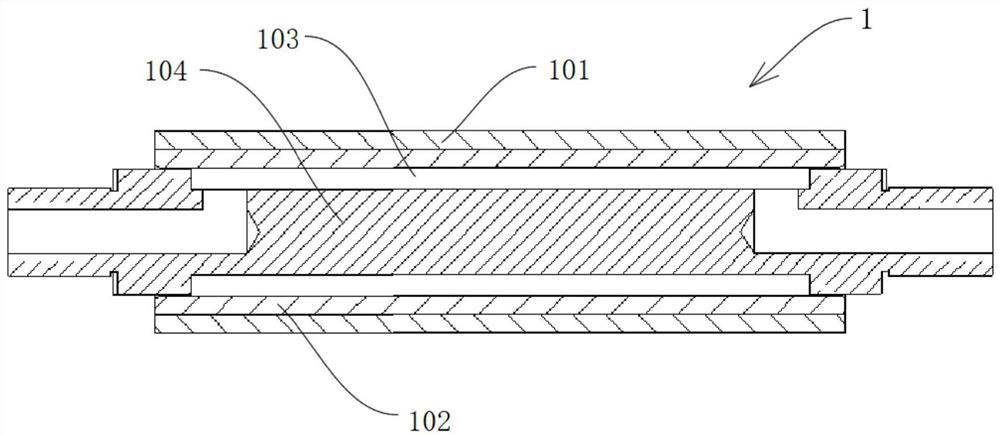

[0033] The fuel charging mechanism 1 is installed on the fuel inlet pipeline of the engine. The fuel charging mechanism 1 includes a high-voltage electric shaft 103, a m...

Embodiment 2

[0037] see Figure 4 , based on Example 1 but differing in that,

[0038] The damping mechanism 3 includes a support rod 301 and an auxiliary fixing block 303. One end of the support rod 301 is rotatably connected to the side end of the upper connecting half-ring 201, and one end of the supporting rod 301 away from the upper connecting half-ring 201 is rotatably connected to a roller 302. The roller 302 A limiting groove is arranged above, and the limiting groove is matched with the roller 302, and the limiting groove is installed on the installation surface close to the engine oil inlet pipeline; the auxiliary fixing block 303 is fixedly connected on the top surface of the upper connecting half ring 201, supporting A damping spring 304 is disposed between the rod 301 and the auxiliary fixing block 303 , and both ends of the damping spring 304 are fixedly connected to the side walls of the supporting rod 301 and the auxiliary fixing block 303 respectively.

[0039] The presen...

Embodiment 3

[0041] see Figure 5-6 , based on Examples 1-2 but differing in that,

[0042] Both the first fuel filter device 5 and the second fuel filter device 6 include a first connecting pipe 501 and a filter body 502, the first connecting pipe 501 is fixedly connected to the communicating pipe 4, and the first connecting pipe 501 is far away from the communicating pipe 4. One end is fixedly connected with the first connecting seat 503, the inner wall of the first connecting pipe 501 and the outer wall and the inner wall of the first connecting seat 503 are provided with thread layers, the filter body 502 is fixedly connected with the second connecting seat 504, the second The second connection seat 504 is fixedly connected with an extension tube 505, the front end of the extension tube 505 is fixedly connected with a first sealing ring 506, the second connection seat 504 and the outer wall of the extension tube 505 are provided with a connecting thread layer, and the extension tube 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com