Forest fire prevention pump

A technology for fire pumps and forests, which is applied to pumps, liquid displacement machinery, transmission parts, etc. It can solve the problems of large space structure, heavy overall weight, inconvenient transportation and transfer, and achieve convenient portability and practical efficiency. The effect of heightening and reducing the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

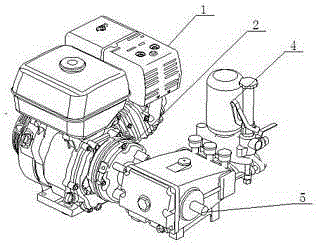

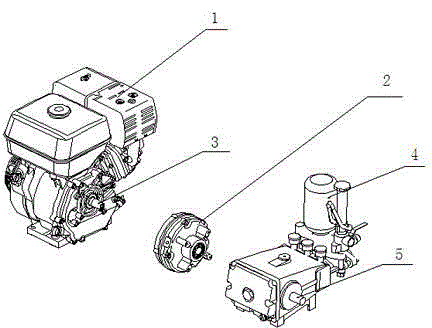

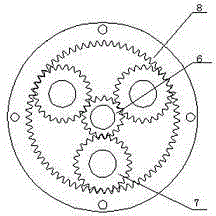

[0016] like figure 1 , 2 , shown in 3 and 4, a kind of forest fire pump comprises engine 1, reduction box 2 and high pressure plunger pump 4, engine 1 is connected with reduction box 2 one ends, reduction box 2 other ends are connected with high pressure plunger pump 4, high pressure The plunger pump 4 is provided with a plunger pump pump shaft 5 passing through the pump body. The engine 1 is connected with the sun gear 6 in the reduction box 2 through the engine crankshaft 3. The sun gear 6 cooperates with the planetary gear 7, and the planetary gear The gear 7 is mated with the ring gear 8, and the planetary gear 7 rotates around the planetary gear shaft 9 on the planet carrier 10;

[0017] The connection mode between the engine crankshaft 3 and the sun gear 6 is taper fit.

[0018] The number of the planetary gears 7 is three, which are uniformly fixed on the planetary gear shaft 9 .

[0019] The planet carrier 10 is fixed on the reduction box back cover 12 through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com