High temperature resistant feed nozzle

A technology of feeding nozzles and nozzles, which is applied in the direction of spraying devices, spraying devices, etc., can solve the problems of increasing equipment investment, achieve the effect of strengthening cooling effect, improving economic benefits, and reducing the number of parking maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

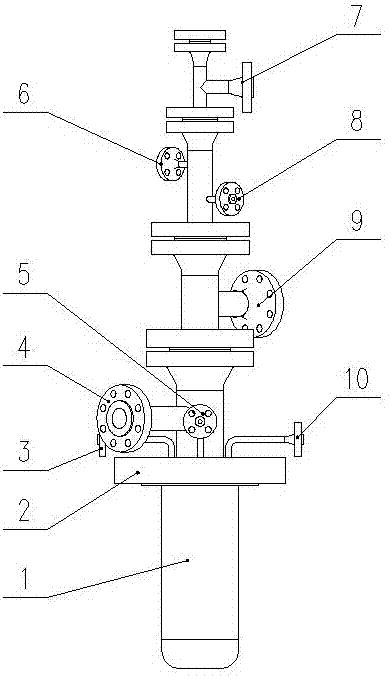

[0029] A high-temperature-resistant feed nozzle, which consists of: a nozzle 1, the nozzle is connected to a connecting flange 2, and the connecting flange is respectively connected to an outer jacket cooling water inlet pipe 3, an outer layer oxygen inlet pipe 4, The nozzle head cooling water inlet pipe 5, the nozzle head cooling water outlet pipe 19, and the outer jacket cooling water outlet pipe 10 are connected, and the outer jacket cooling water outlet pipe is connected to the material inlet pipe 9 through a connecting flange. The material inlet pipeline is respectively connected to the inner cooling water inlet pipeline 8 and the inner cooling water outlet pipeline 6 through connecting flanges, and the inner cooling water outlet pipeline is connected to the central oxygen inlet pipeline 7 .

Embodiment 2

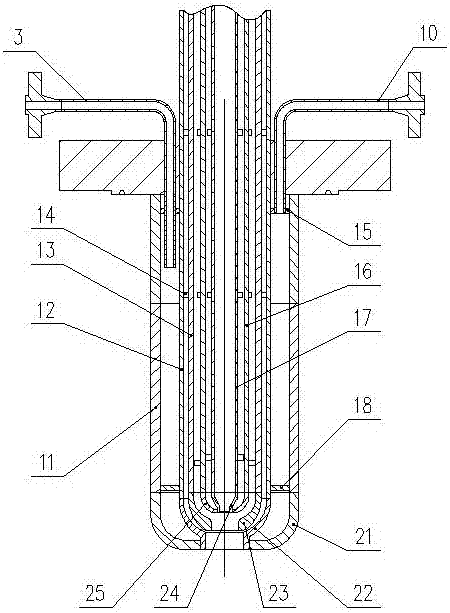

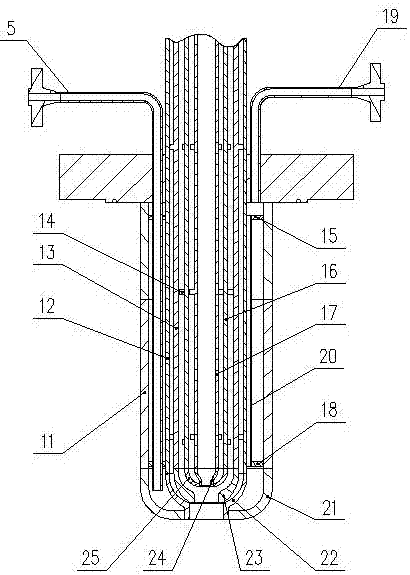

[0031] According to the high temperature resistant feed nozzle described in embodiment 1, the exterior of the nozzle is composed of the outer nozzle head 21 and the outer nozzle cylinder 11 respectively.

Embodiment 3

[0033] According to the high-temperature-resistant feed nozzle described in embodiment 1 or 2, the inside of the outer layer nozzle head is respectively equipped with a sub-outer layer nozzle head 22, an intermediate layer nozzle head 23, an inner layer nozzle head 24, and a secondary layer nozzle head. Inner nozzle head 25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com