Technical method for improving precision of RV reducer

A process method and reducer technology, applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult to eliminate assembly gaps, troublesome implementation, and lack of accuracy, so as to eliminate gaps, eliminate manufacturing errors, The effect of accurate research and combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

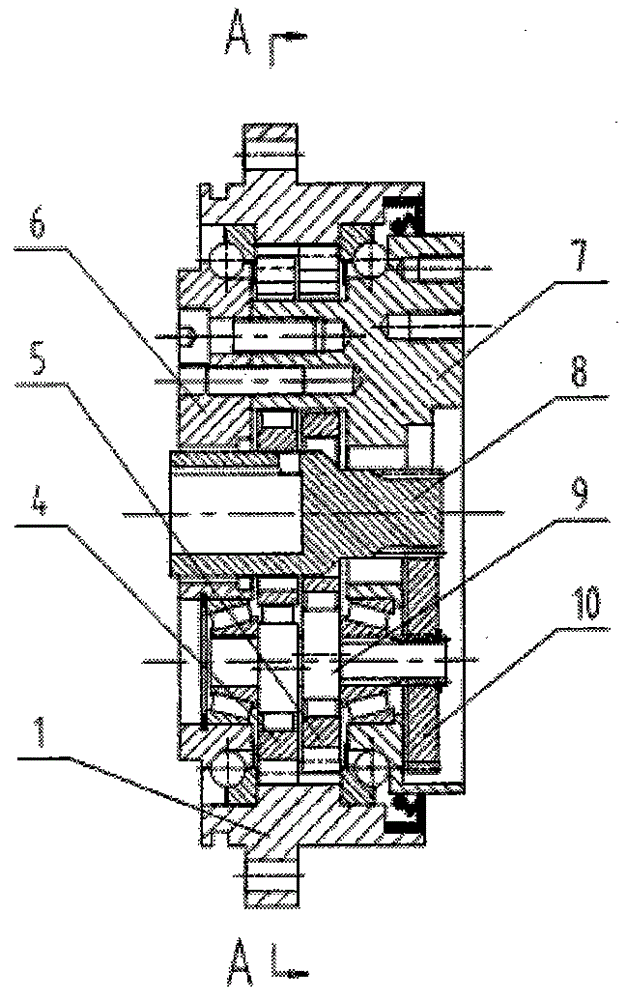

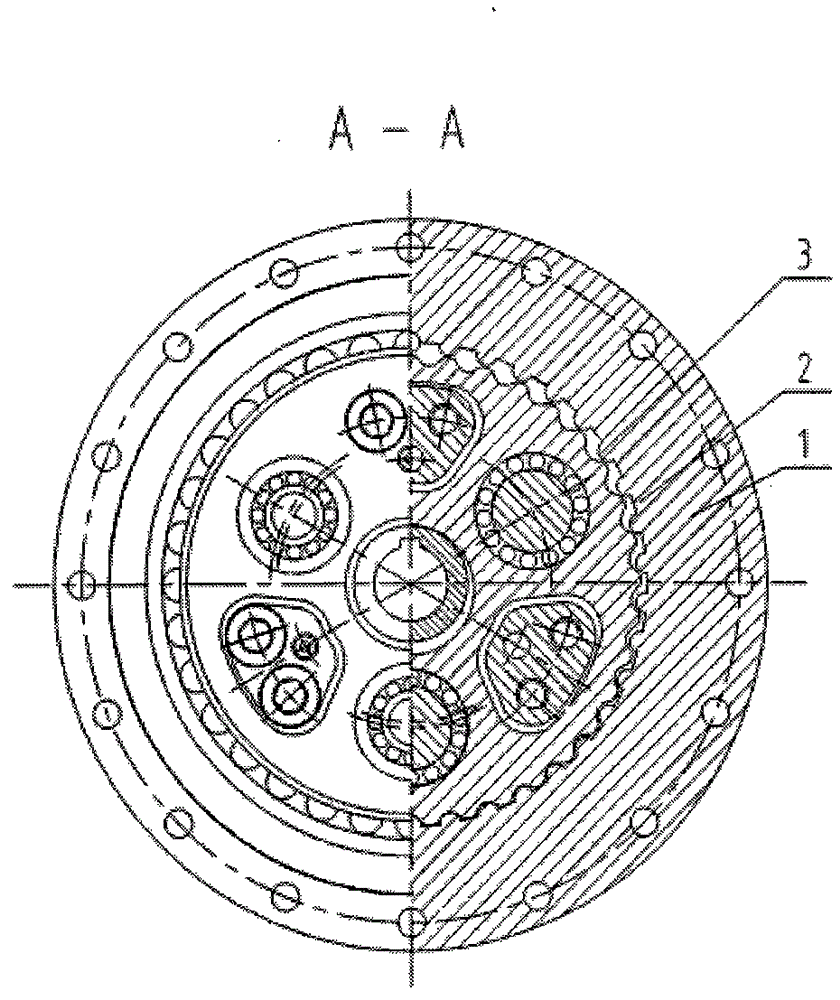

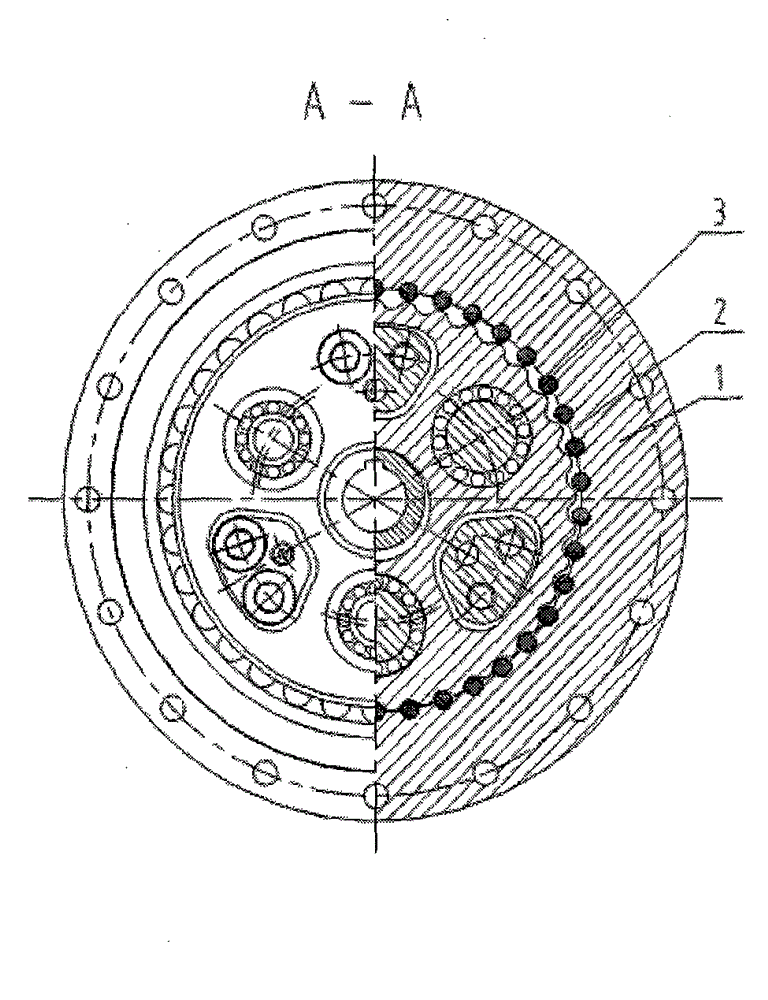

[0036] According to Embodiment 2 of the present invention, the implementation steps of the process method for improving the precision of the RV reducer include:

[0037] 1. Manufacture the components of the RV reducer according to the requirements, and make the size of the RV gear 4 and 5 slightly larger than the required size;

[0038] 2. During assembly, the RV gears 4 and 5 are cooled to reduce their diameter, so that the slightly larger RV gears 4 and 5 can be assembled with the internal gear 2;

[0039] 3. Add grinding agent at the junction of RV gears 4, 5 and internal gear 2;

[0040] 4. Through the temperature control of the housing 1, in the case of keeping the RV gears 4, 5 and the internal gear 2 in close contact but still able to rotate, the reducer is driven to run, and the RV gears 4, 5 and the internal gear are realized by means of the grinding agent. The self-adaptive grinding between the two until the temperature reaches the ambient temperature of the RV redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com