Composite pipe inner weld grinding machine

A composite tube and grinding machine technology, which is applied to the parts of grinding machine tools, machine tools and grinding machines suitable for grinding the edge of workpieces, etc., which can solve the problems of affecting product delivery efficiency, affecting finished product delivery efficiency, and low manual grinding accuracy. problems, to achieve the effect of convenient grinding, fast grinding speed and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, technical features, invention objectives and technical effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

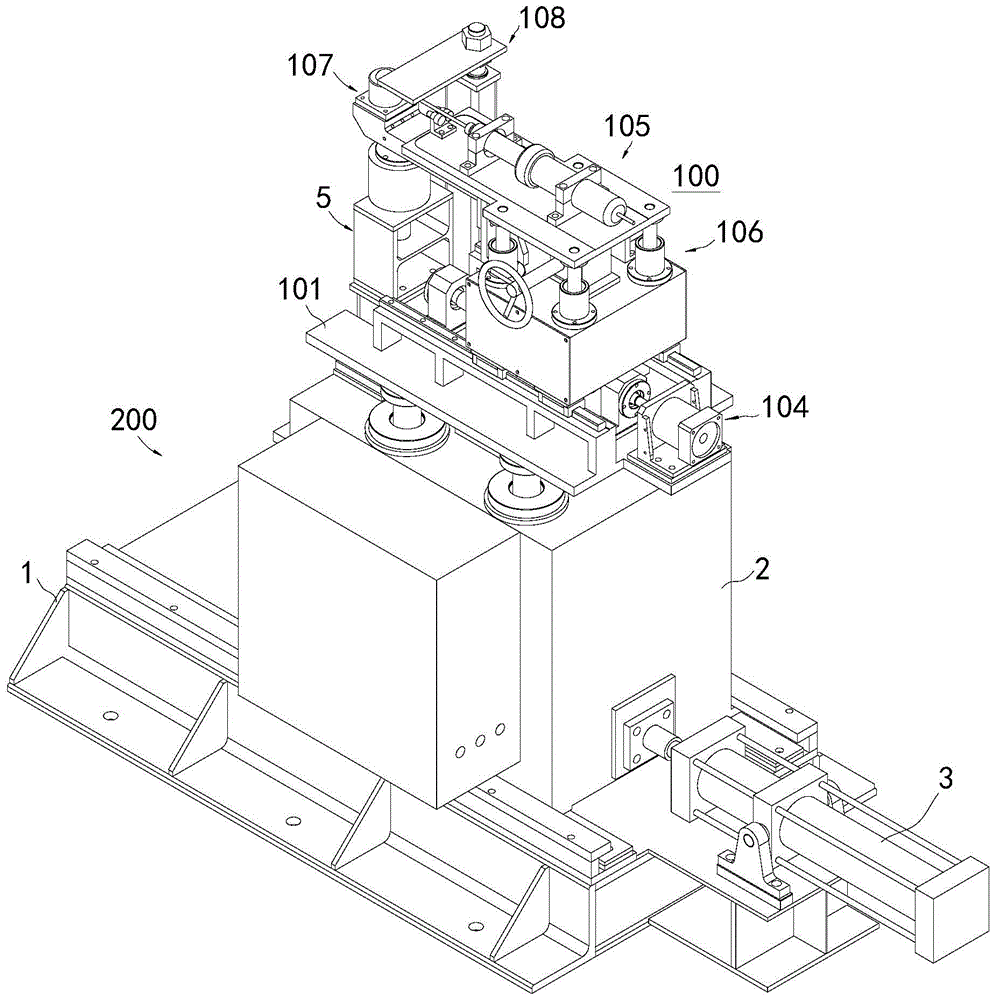

[0030] like figure 1 Shown is a compound pipe internal weld grinding machine of the present invention, including a grinding feeding mechanism 100 , a metal pipe follower mechanism 200 and a retaining wheel mounting seat 5 .

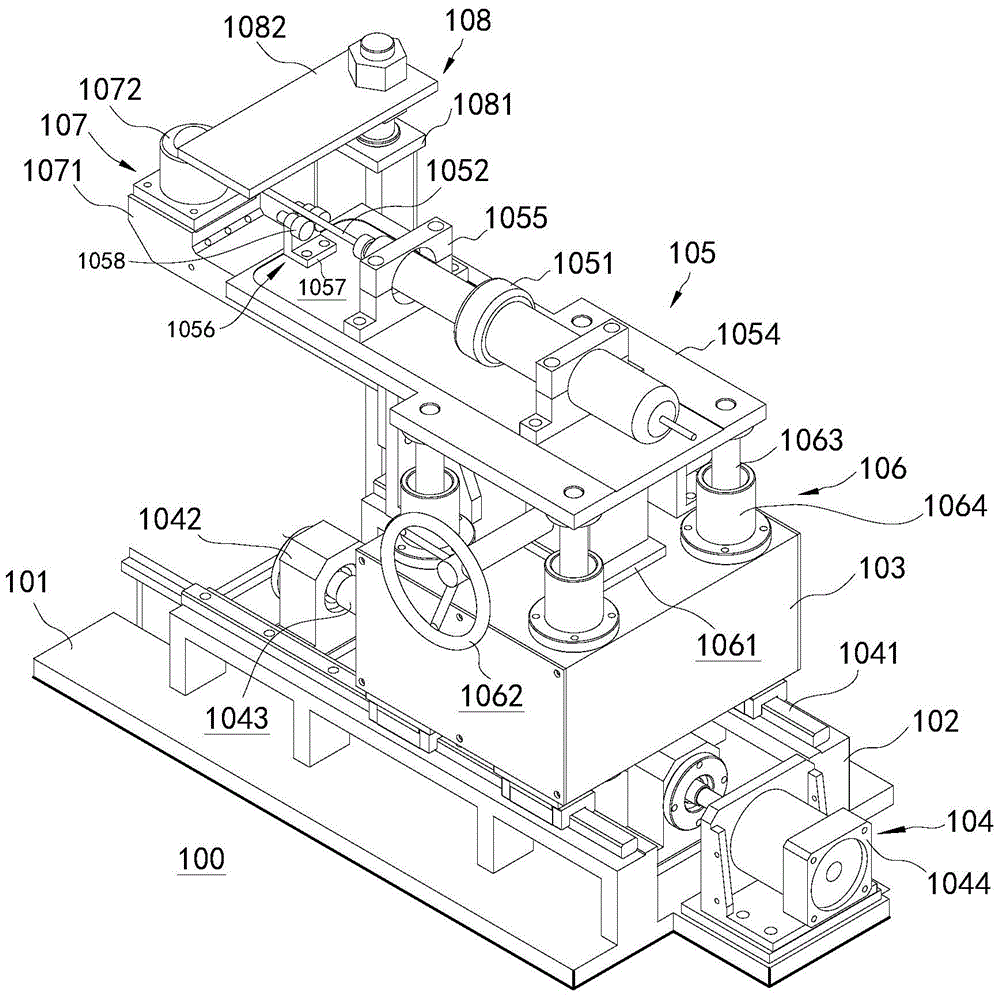

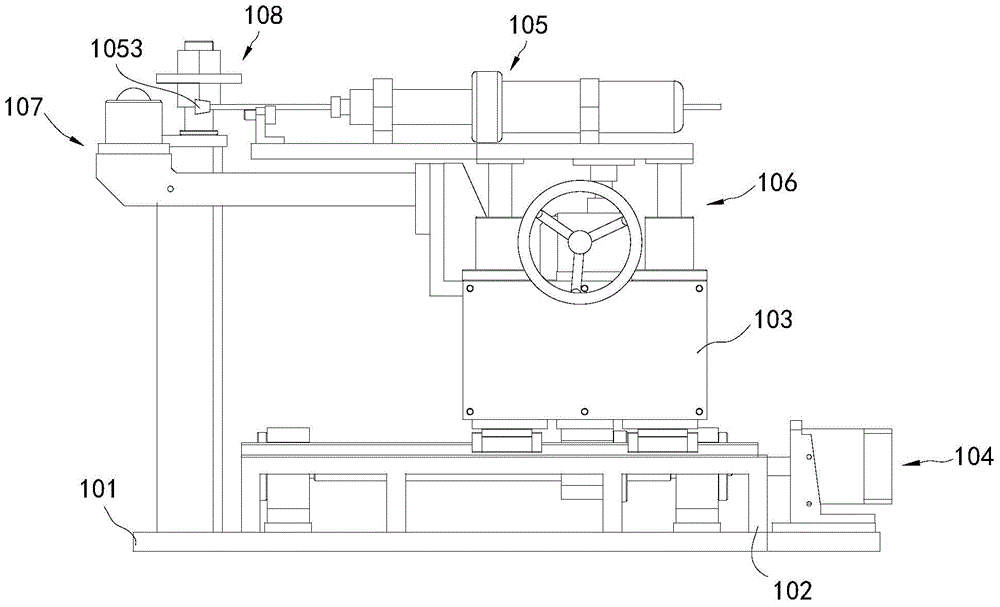

[0031] like figure 2 , 3 The grinding feeding mechanism 100 of the present invention shown includes a mounting base 101 and a mounting bracket 102 provided on the upper surface of the mounting base 101 .

[0032] The grinding and feeding mechanism 100 of the present invention also includes a moving seat 103 , a moving mechanism 104 , a feeding mechanism 105 and a grinding head lifting and fine-tuning mechanism 106 . The moving base 103 is installed on the mounting bracket 102 through the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com