Shot blasting machine comprehensive improved derusting method

A shot blasting machine and fan technology, which is used in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc. Market prospects and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

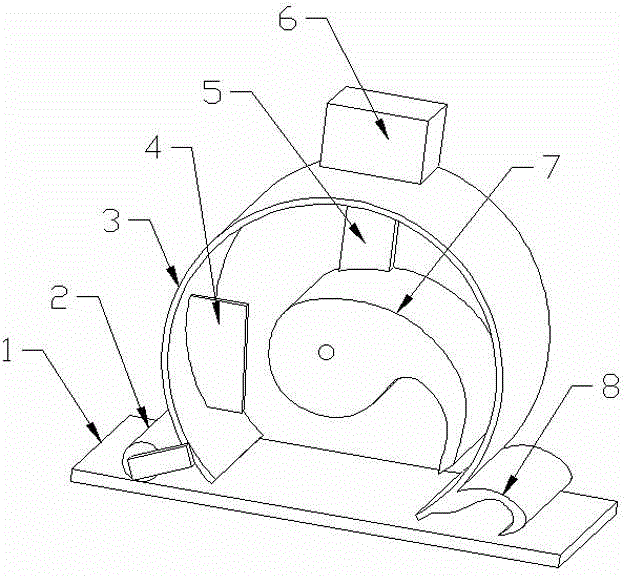

[0018] The shot blasting machine comprehensively improves the rust removal method, including steel plate 1, power wheel 2, casing 3, guide piece 4, fixed rod 5, material box 6, fan 7 and scraper 8, including the following steps:

[0019] A Place the equipment on the steel plate 1, and load the shot blasting raw materials in the material box 6;

[0020] B and then turn on the power wheel 2 and the fan 7, the power wheel 2 moves with the entire shell 3, and at the same time the shot blasting raw materials enter the shell 3, and under the blowing of the fan 7, the contact surface of the steel plate 1 is continuously rolled back and forth. 3 is attached to the steel plate 1, so it will not leak out;

[0021] C. When there is a protrusion on the steel plate 1 during the movement, it can be scraped off by the scraper 8 at the rear, which greatly improves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com