Metal energy dissipation damper

A damper and metal technology, which is applied to building components, building types, earthquake resistance, etc., can solve the problems of complex damper structure, unfavorable popularization and application, and increased project cost, so as to achieve good market promotion and application prospects, clear energy consumption mechanism, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A metal energy dissipation damper of the present invention will be further described in detail below in conjunction with the accompanying drawings.

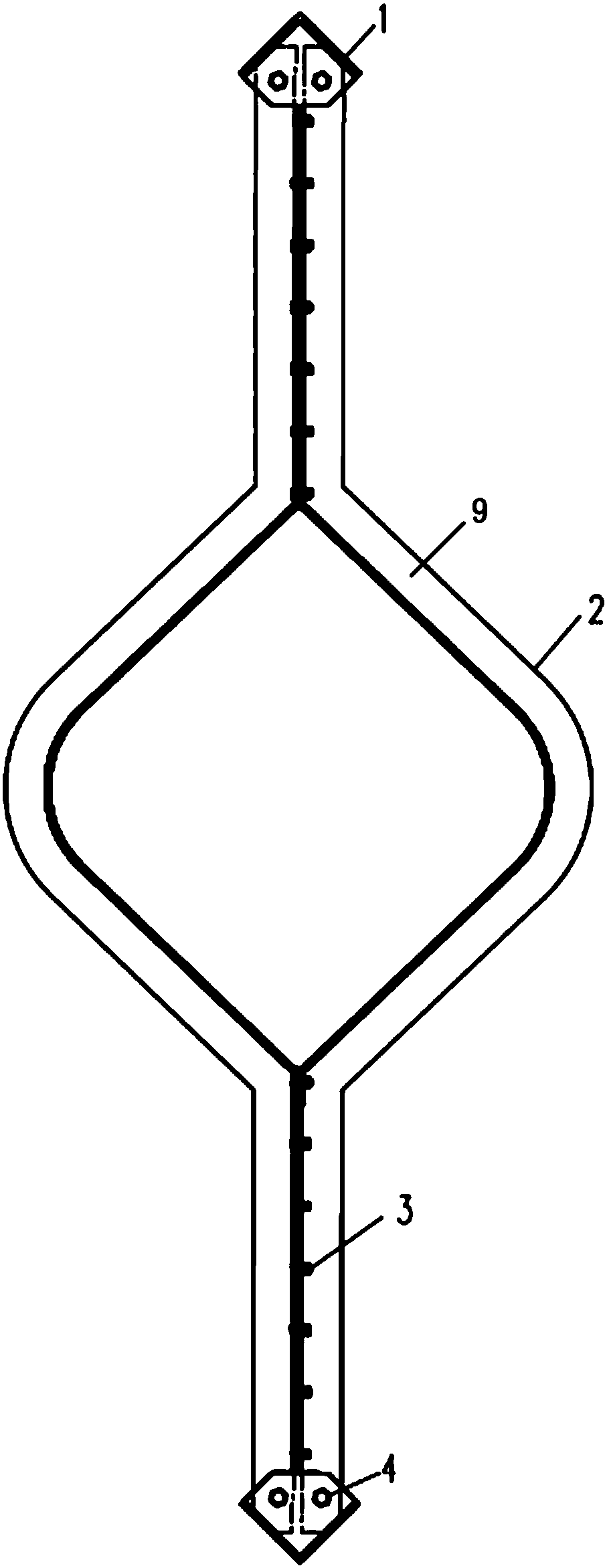

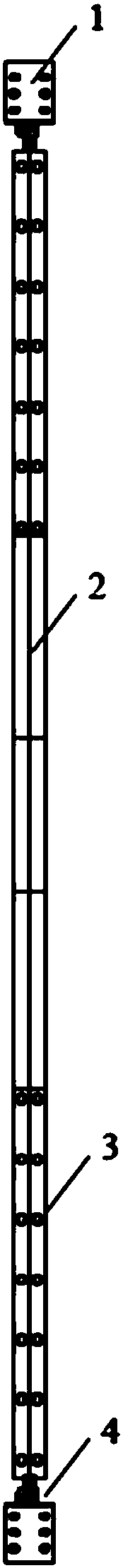

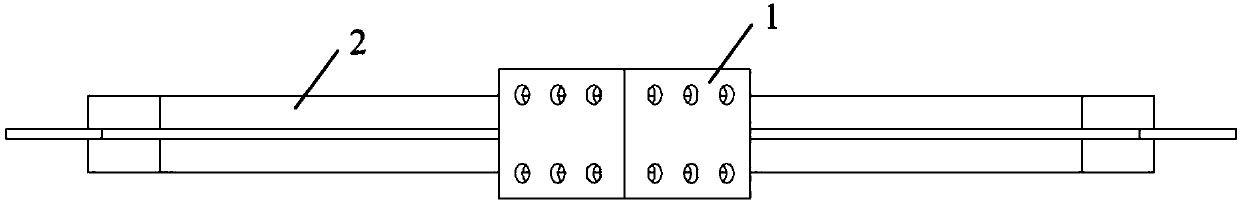

[0027] like Figure 1 to Figure 5 As shown, a metal energy dissipation damper of the present invention includes a connector 1 and a metal energy dissipation element 2, the connector 1 is fixedly connected to the building, the metal energy dissipation element 2 is connected to the building through the connector 1, and the metal energy dissipation element 2. It consists of a pair of T-shaped cross-section steels, which are relatively bent in the middle and then bolted and welded. The metal energy dissipation element 2 is divided into a straight line segment and an arc segment, and the two ends of the arc segment are respectively connected to the building through the straight line segment and the connector 1 . A plurality of first bolts 3 are arranged on the straight section of the metal energy dissipation element 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com